First of all if you ever hear of me wanting to do this again please send me a self addressed envelope and I will send you a plane ticket to come down here so you can kick me in the nads. Holy moly what a chore. I spent 5 1/2 more hours on it after my last update. It really ended up being a test of will. The barrels were still riding high so I kept at it and had to work on about 7 areas simultaneously to end up with what I hope is a good fit. There is at least 85% breach face contact and the barrel flats are almost 50 contact with the tightest being over the pin. I polished the barrel face with 320 grit. Any reason to go finer?

The extractor fitted just fine and operates properly but I did note that one of my shot shell brands did fit tight but I tried about 5 others and they were fine. I will forgo messing with rim depth cutting for now. I have not checked hook/lever contact yet but it feels pretty smooth with some good travel.

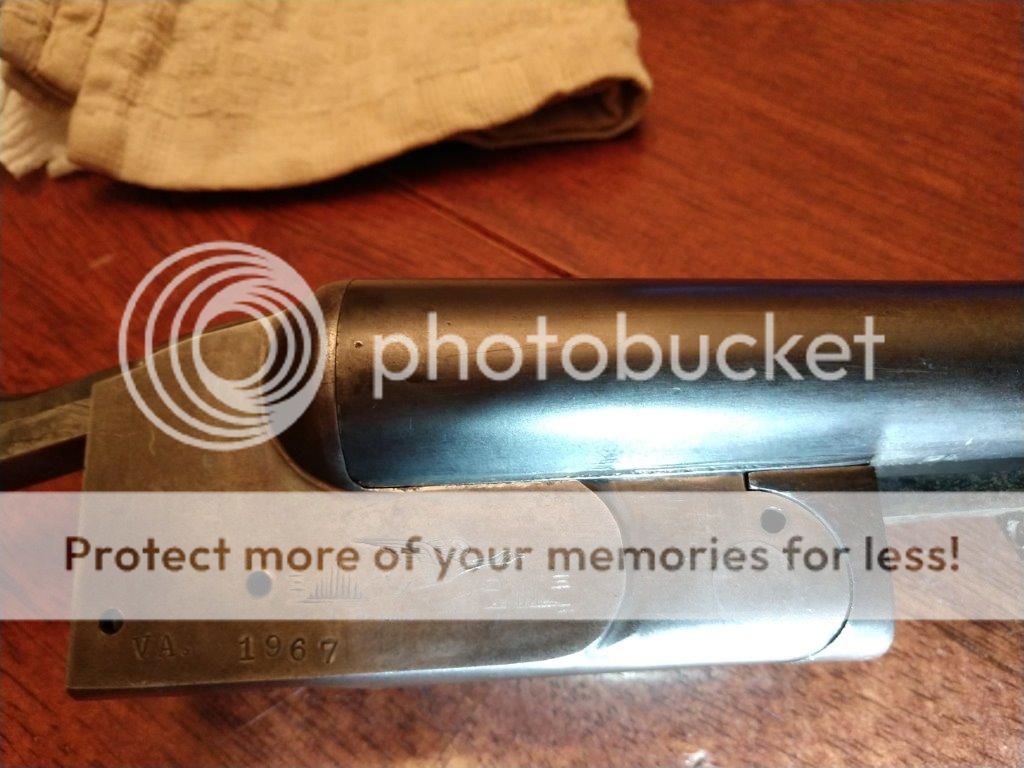

Many thanks for the input and direction. Pics of what I hope is the final product. At the risk of jumping off a bridge, if you see something that needs attention I guess go ahead and tell me

Thanks again