|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,465

Posts545,070

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Jan 2002

Posts: 707

Member

|

Member

Joined: Jan 2002

Posts: 707 |

Jack, SAAMI maximum average working pressure for 12 gauge is 11,500 psi (as stated above).

A proof pressure for SAAMI loads of 1.5 x working is between 17,000 - 18,000 psi, hence proof loads of ~ 18,000 psi, as you surmised. This is also essentially equal to the 1,200 kg/sq cm "heavy" proof used optionally in Spain and similar levels available in France and other countries.

Fred

|

|

|

|

|

Joined: Jan 2006

Posts: 9,416 Likes: 313

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,416 Likes: 313 |

I think it's reasonable to view the 3 Ton/650 bar/10,730 psi pressure as the maximum service/using pressure rather than the standard/recomended service pressure. The Gamebore loads run below 8500 psi but are 'approved' for use in 3 ton/650 bar service/850 bar proof guns.

Last edited by revdocdrew; 04/03/07 02:36 PM.

|

|

|

|

|

Joined: Jan 2002

Posts: 11,377 Likes: 105

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 11,377 Likes: 105 |

Straight from the Birmingham Proof House, which is the most reliable source I know of when it comes to questions about proof, service pressure etc on British guns:

"The equivalent transducer values that should be used for comparison with SAAMI transducer values are 740 bar service and 960 bar proof, i.e. 10,730 psi (service) and 13,920 psi (proof)."

This was in responce to my post stating the "Older" 3 ton service pressure had been shown by "Simultaneous" crusher & tranducer readings to give an "Actual" reading of about 8960psi. ""IF"" the actual pressures used have not changed then I read that as saying those old pressures were in fact 10,730 "Actual" psi's. Peresonally I need a litle more proof to show they were. I did state verbatin where my figures relating 3 ton to 8960psi derived from. You strongly implied they were all wrong & you had the final word from the Birmingham Proof House. However everything you quoted was for post 80's "Metric" figures. I do not believe these to be totally applicable to the earlier proofs, but could possibly be proved wrong. If so then 10,730 it is. Miller, I'm a writer. I do this stuff for a living. A review of my previous post--the one you quoted--shows no references at all to anything about guns marked with "tons". However, the paragraph preceding the one you quoted does, in fact, refer specifically to guns with the bars proofmarks. But just to make clear, the only thing I'm certain of is that the 10,730 and 13,920 psi figures are the transducer equivalents for service pressure and proof pressure, respectively, of guns proofed under the CURRENT system. Thus, you may have INFERRED something from my post, but it was nothing that I IMPLIED. I made that clear in my most recent post, when I said that I would contact the Birmingham Proof House to clarify proof and service pressures for guns from the "tons" and earlier eras. I have done so; currently awaiting a reply.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

...It seems like the guage would impact pressure, and a 16 ga at 3 tons and a 12 ga at 3 tons would need to take different pressures, or the 16 ga would need thicker or stronger barrels?

Pressure does not equal recoil, because recoil is measured in foot pounds.

U.S. manufacturers are not as concerned with pressure because they are trying to meet a different standard i.e. FPS, and change powders from time to time resulting in different pressures, but the same FPS.

....It sounds like there is a mimimum standard the Brits are trying to meet for all guns. For that matter same goes for U.S. guns, and maybe guns imported for use in U.S.? Ok, 1st, I am not going to even touch the CIP/BAR/TON/PSI/PIEZO/CRUSHER discussion...the relationship is a curve so a simple linear expression will not be accurate in all instances. Recoil and pressure are related. However, the relationship is complex. The calculation to arrive at chamber pressure includes many more variables. Perhaps a definition of pressure is needed. From the SAAMI website: PRESSURE

In a gun or cartridge, the force imparted to various components that is developed by the expanding gases generated by the deflagration of the propellant when fired. So you press the trigger and a lot of energy is released. Where is going? Up the barrel? Well only to a degree, few things are 100% efficient. WHERE DID IT GO?

A pound of single-base rifle powder has an energy content of about 1,246,000 ft-lbs of energy or about 178 ft-lbs per grain of powder. In actual practice only a fraction of this energy is available to accelerate the bullet. Julian Hatcher in HATCHER'S NOTEBOOK reported the energy distribution for the Browning Machine Rifle as follows:

Heat to cartridge case 4%

Kinetic energy to bullet 29%

Kinetic energy to gases 19%

Heat to barrel 22%

Heat to gases 19%

Heat to bullet friction 7%

Total = 100%

You will note that the energy imparted to the bullet is only about 29% of the total powder energy available. While this is typical of many small arms cartridges, actual efficiencies may range from 17 to 37 percent or more. The actual efficiency is basically a function of expansion ratio and charge weight to bullet weight ratio. As you can see, one event causes multiple responses. Gun powder is burnt. Gases are released. The load begins to move. The barrel starts to flex in 3 dimensions. Heat is generated. Part of this is measured in recoil. A simple law of Newtonian physics, "For every action there is a reaction". But something more complex is occurring. In part the burn rate of the powder, not just how many grains you used, plays a role in determining pressure. Think of it this way. If you are lighting a BBQ and all you have is some paper, the flame takes a while to get going. Soak a little starter fluid on the paper and it burns at a very different rate. With gun powder the size, shape and detergent coatings play a role in determining the burn rate. Did you ever look a burn rate chart? They are very informative: http://www.reloadbench.com/burn.htmlhttp://www.reloadersnest.com/burnrates.aspAmmunition manufacturers use very precise calculations to determine the loads they develop. Then they do a lot of pressure tests and chronographing of the projectile. They walk a thin line. Their goal is to produce a load with a certain muzzle velocity while keeping the pressure within SAAMI standards. They are dealing with a working pressure that has been established, requiring that the powder burning rate (relative quickness) be matched to load acceleration to produce optimum velocity. For a given pressure the optimum velocity can only be obtained by maintaining the accelerating force for a longer or shorter period of time. To think that the British companies have a different objective than American, than Italian, than German is not true. They are all relying on the same buyer. What is true is a relatively small percentage of shooters choose to shot a 100 year old gun with 2 barrels that was proofed using methods no longer in use. Most prefer a semi-automatic and Wally World Wonder Shells. Pete

|

|

|

|

|

Joined: Jan 2006

Posts: 9,416 Likes: 313

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,416 Likes: 313 |

Just heard back from B&P regarding their speed/pressure chart:

"The B&P Pressure chart has nothing to do with SAAMI. Those are the actual PSI( pounds per square inch ) for the actual Baschieri & Pellagri loadings that we import into the United States."

Looks like their psi is CIP/LUP (which explains why their bar to psi conversions fit the formula) and we need to add 1000 for a rough approximation of SAAMI pressure.

Last edited by revdocdrew; 04/04/07 12:01 PM.

|

|

|

|

|

Joined: Aug 2006

Posts: 322

Sidelock

|

OP

Sidelock

Joined: Aug 2006

Posts: 322 |

From a separate post it sounds like RST will tell folks the PSI for various loads they offer.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,416 Likes: 313

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,416 Likes: 313 |

I had no problem getting the pressure infro from RST, Polywad, Fiocchi, Kent, Gamebore, or the Bismuth folks. Federal responded but was vague "It generally runs between 9000-10,500 psi" Remington, Eley, and Winchester never responded to my requests, and I intend to purchase shells from those that did.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

"Those are the actual PSI( pounds per square inch )"

Note that if these are LUP pressures then they "Are Not" actual psi. We poor peons will never sort all this out until the makers & proof houses decide to use correct terminology. 1 actual psi should be 1 psi whether measured by SAAMI, CIP or whoever. Some 40 yrs ago we of the US quit using the psi term except on those pressure recorded by the tranducer method which repotedly gives correct readings. Others are listed as LUP's or CUP's depending upon the crusher metal. The 14.503 conversion factor between psi & bar is based upon "Actual Correct" pressure readings, not crusher pressure.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Jan 2002

Posts: 11,377 Likes: 105

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 11,377 Likes: 105 |

"Those are the actual PSI( pounds per square inch )"

Note that if these are LUP pressures then they "Are Not" actual psi. We poor peons will never sort all this out until the makers & proof houses decide to use correct terminology. 1 actual psi should be 1 psi whether measured by SAAMI, CIP or whoever. Some 40 yrs ago we of the US quit using the psi term except on those pressure recorded by the tranducer method which repotedly gives correct readings. Others are listed as LUP's or CUP's depending upon the crusher metal. The 14.503 conversion factor between psi & bar is based upon "Actual Correct" pressure readings, not crusher pressure. Precisely! What B&P is doing--quite easy to see, from their charts--is a straight conversion from bars to psi. What we know, from the Birmingham Proof House, is that the bar readings are not always transducer measurements. If they're crusher measurements, then the formula does not yield the answer in REAL psi. That's why our reloading manuals specify pressures in either psi or, occasionally, in LUP. If it's in LUP, then we know that figure was arrived at under the crusher rather than the transducer system, and about the best we can do is a "ballpark" conversion to psi by adding 1,000. Build in something of a fudge factor to be on the safe side and that's good enough for reloading purposes. But as we've seen from the Brits, if we assume crusher bars to be transducer bars and attempt to do the math, we're going come up with a psi total that's quite a ways off--although at least it's off on the safe side. Still awaiting a reply from the Birmingham Proof House. I'll post it as soon as I hear. I think all of us that play with older Brit guns would like to have some more definitive answers.

Last edited by L. Brown; 04/04/07 04:36 PM.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

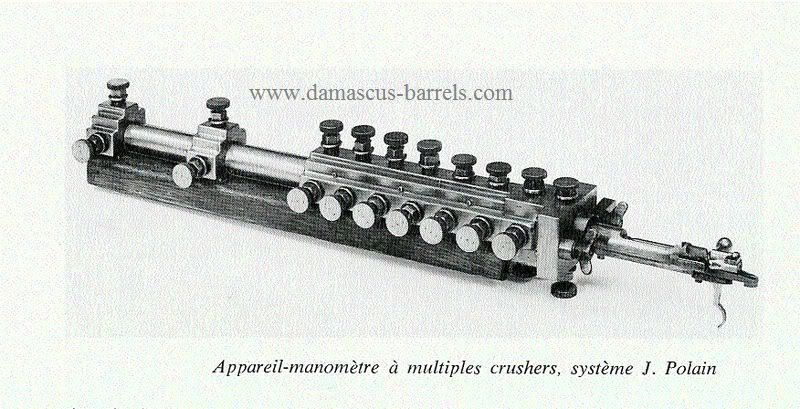

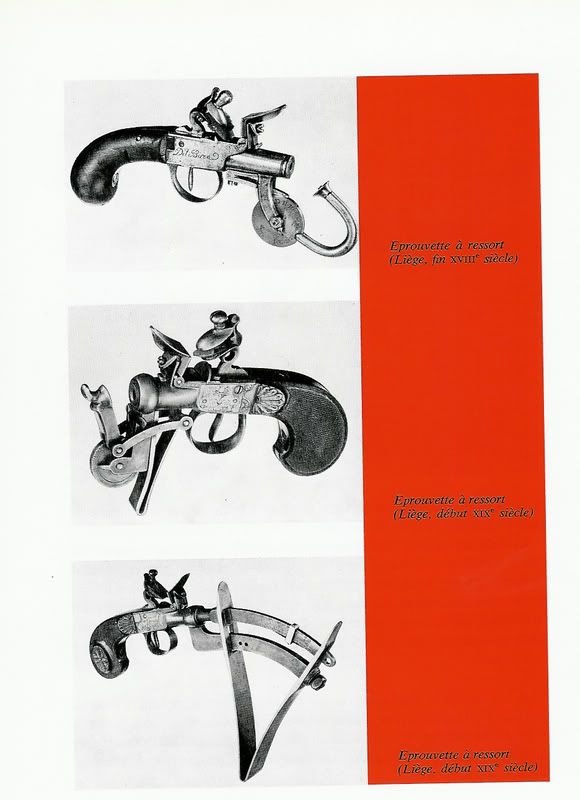

I thought these might be interesting to see. From a recently acquired book... 1895 Crusher jig - Liege  circa 1900 multiple crusher test setup - Liege  Various powder testers - Liege  Pete

|

|

|

|

|