|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

|

7 members (battle, rocky mtn bill, bigblock, ClapperZapper, Roundsworth, 1 invisible),

1,012

guests, and

5

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,504

Posts545,552

Members14,416

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Dec 2001

Posts: 6,994 Likes: 402

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 6,994 Likes: 402 |

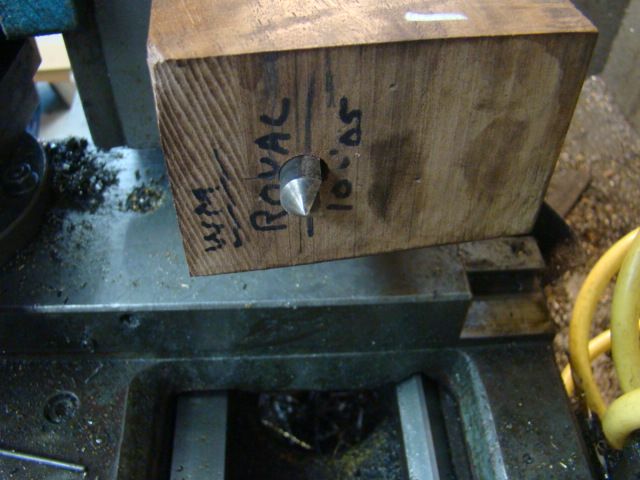

This topic comes up from time to time so I thought I would post my method. Slow feeds and speeds, continually checking alignment are key to getting things to come out properly.The stock blank is clamped in a milling vise attachment, lined up using the tail stock center on one end and the tip of the gun drill bit on the other. You can not rush this operation as heat will build up and if you are not careful you can twist the blank in the milling vise. Patience is your friend on these type of holes.    You can see the bit has now emerged from the blank in exactly where I had planned it. Bushing are now made for both the stock blank and the pattern stock with the through bolt hole being the center for both. Steve

|

|

|

|

|

Joined: Jan 2004

Posts: 6,727 Likes: 417

Sidelock

|

Sidelock

Joined: Jan 2004

Posts: 6,727 Likes: 417 |

Nice work. Any idea how to do this for a muzzleloader where the hole is deep but there is no outlet or way to target between points? One of these days I have to get back to building a pistol-grip Hawken and that hole is the single biggest problem.

Why did you not use a brad point bit? I understand they are a bit more likely to go straight, but I have no experience.

_________ BrentD, (Professor - just for Stan) ![[Linked Image from i.imgur.com]](https://i.imgur.com/qclHjMQ.jpg)

|

|

|

|

|

Joined: Dec 2001

Posts: 6,994 Likes: 402

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 6,994 Likes: 402 |

That is gun drill, designed for deep straight holes, sold by TOW for drilling ram rod holes. The premise is the same but even more careful measurement is required. Additionally a simple jig can be made to keep the hand drill in line. The drill is about .405" in diameter. The jig is simply a hardwood block with a corresponding U shaped notch milled in to it. The block is then clamped to your stock blank giving you the line you desire. I saw pictures of the set up in one of the better books on building muzzle loaders. If I can remember I'll see if I can dig it up.

Steve

|

|

|

|

|

Joined: Feb 2009

Posts: 7,464 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,464 Likes: 212 |

Thanks for the additional comments on the drill bit Steve. It must be a little different to clear chips after it gets in there a way.

|

|

|

|

|

Joined: May 2007

Posts: 66

Sidelock

|

Sidelock

Joined: May 2007

Posts: 66 |

Not to hijack this but I pretty much do it the same. I chuck up the gun drill in the headstock and start the hole with a short hole the same diameter as the gun drill, mount the stock blank against the tailstock center and push it into the the gun drill. I only go about half way, clear out the chips often and turn the stock around to finish. It never ceases to amaze me how the holes meet in the middle. The secret is in the gun drill, I make my own with a piece of drill rod. For the head of the screw, oversize, I have a 7/8" twist drill, 1/2" shank, with a pilot ground to the tip to match the gun drill.

Jim

Jim

Member American Custom Gunmakers Guild

|

|

|

|

|

Joined: Sep 2011

Posts: 150 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2011

Posts: 150 Likes: 2 |

Brent,

The thimbles will work as a guide for a Hawken.

Might have to bush them if oversize, But check, double check and re-check alignment.

Use a flat pointed drill made from drill rod. Scrapes (cuts) only on the front and cannot wander. Plenty of Paraffin on the shank. Slow, maybe, but works.

Chuck

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

3/8" gun drill with extension for ramrods or through bolt holes.  Another view  Flat counterbore with swivel pilot for bolt head & washer, big enough for the socket wrench

There are instructions and pics on my web site showing how to drill a magazine tube hole for a lever action forend essentially the same way.

Last edited by SDH-MT; 04/29/16 12:38 AM. Reason: edit

|

|

|

|

|

Joined: May 2007

Posts: 66

Sidelock

|

Sidelock

Joined: May 2007

Posts: 66 |

Steve, what advantage do you have using a left hand twist on the gun drill? And, don't you need to clear it quite often with the short flute?

Jim

Member American Custom Gunmakers Guild

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

It is not a "left-hand twist", the 90* face does the cutting. Yes, the short flute has to be cleared often. Drills dead straight. I also drill half distance from each direction.

Half-stock ramrod holes are drilled using two under-rib and thimble guides, or fullstock in a perfectly aligned ramrod channel. Approximate ramrod location is confirmed with a small hole drilled under the barrel breech.

I've drill dozens of each with this drill.

|

|

|

|

|

Joined: May 2007

Posts: 66

Sidelock

|

Sidelock

Joined: May 2007

Posts: 66 |

You are correct, I looked at mine and they are the same, right hand twist, yup, they just work

Member American Custom Gunmakers Guild

|

|

|

|

|