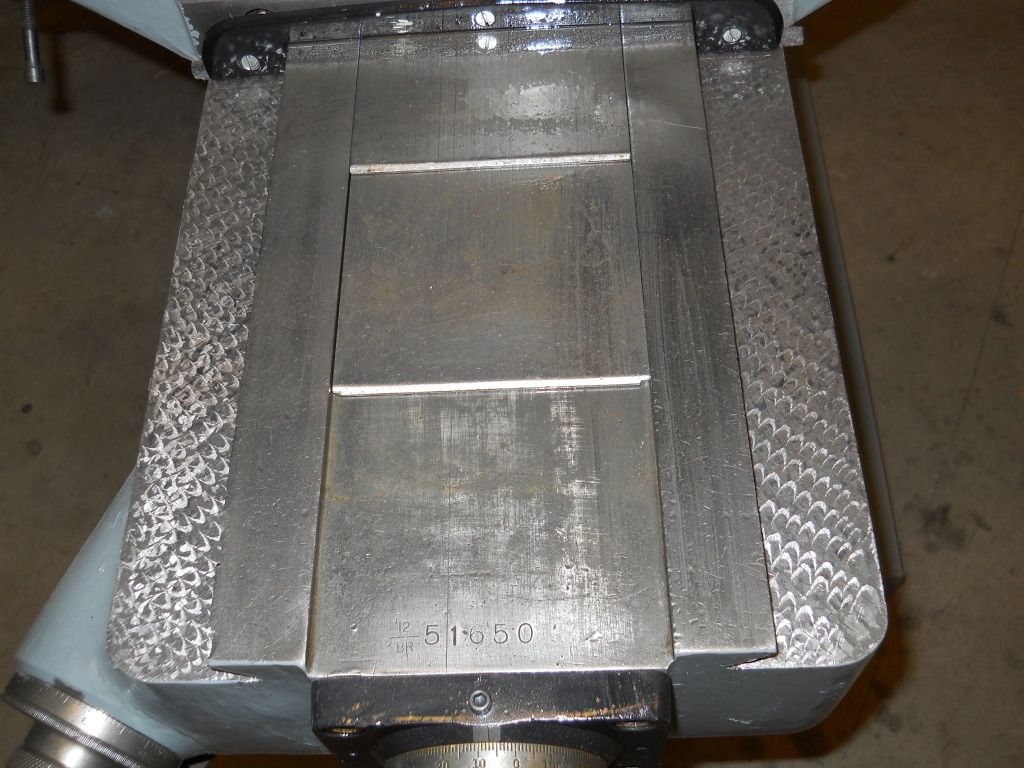

Recently, I picked up a sporterized Mauser. I won't say

custom because the quality isn't that great. It was on

an all matching WWI Mauser action with a pre-64 Winchester

Model 70 barrel. But what I did find interesting was the treatment of the bolt, it wasn't jeweled, I don't think this

is scraping. I think I know what was done to it but I'd like

to read the opinions of others. Here are two pictures.

Looks like it has been "scraped" somewhat like a lathe bed is scraped to get a flat and parallel surface. It has been done in the past to help the bolt hold lube. Michael's book, I believe, remarks on this treatment in one of the chapters. I suspect it could have been done better.

The treatment goes by various names. It was common on Neidner rifles, and Tom Shelhamer continued the practice for as long as he continued building rifles. I would be interested in seeing the rest of the rifle.

Thanks for posting.

John

At first, I thought it was scraped too. But I think

I am conditioned to believe that if it isn't jewelling then it is

scraping. Now I think it is something different. Any other

thoughts. I will take some pictures of the rifle tonight, but

trust me, it is nothing special.

This surface treatment looks like a different process than G&H used on their bolts, which was truly a scraped finish. This type can be done with a pointed stone chucked in a drill press and simply run over the lightly oiled bolt surface under light pressure. It takes a while to get much "coverage", but it's easy to do and has a nice visual effect.

Looks like some sort of etching to me, but I can't understand why it doesn't end evenly toward the rear or go all the way back to the bolt handle. That makes me wonder if it was even intentional.

IMO...leaving a bunch to be desired. Thank god someone figured out jeweling.

I think I see a little bit of pitting? Has the look to me like someone tried to clean it up with a small abrasive rubber wheel or point on a dremel. After a while, they probably realized it wasn't working like they imagined, and figured, do a quick even up all over. I haven't seen many scrape surfaced parts, but I think scraping appears much cleaner.

I will give you my opinion when I see a picture of the complete rifle.

It looks scraped to me.

Mike

Bill has the answer,the operator quit too soon.I think it would look nicer with a little more coverage.

well, things are busy here, we have 2.5 year old twins.

So here is a link to the rifle on the auction site

Mauser 30-06 On one hand having high resolution images tends to make

things look worse, on the other hand, I do believe the pictures

show clues to how it was done. I still don't believe it was scraping. But I will give people some more time before I offer my opinion.

You could not go wrong, if the Lyman Alaskan scope is decent they usually go for around $200 on ebay.

The scraping looks like the work of John Oberlies or similar. Unfortunately, the rifle was not built by Oberlies.

looks like good scraping to me, function is whats important.the idea is for a smooth bolt travel.jeweling is an easy and inexpensive way to do the job.mc

This is slightly off the beaten track, but is this scraping and jewelling truly effective or is this just part of the gun-culture mystique? I can't see why making something rougher is a good way to make something smoother. I don't see this being done to bearings for instance.

I apologize for side tracking a little here, but this has always mystified me. Makes no sense at all that I can see.

jeweling or scraping not only holds oil better reducing friction, but it also reduces surface area contact reducing surface tension/drag.

Kind of along the lines of the hulls on race boats. Most racers will scuff up the hull where it meets the water, not polish it smooth and wax.

Bearings don't apply to this theory as they roll instead of drag.

gunmaker, I know that is the reason given for jeweleing, but does it actually work? Again, I never see such surfaces in other friction-reducing applications such as a bearings or rails made for sliding metal against metal. I can't feel any difference either. But I don't have any particularly objective data to offer in support of anyone's claim one way or the other.

very common on the ways of a milling machine....

It is not neccesary for proper function. In the great majority of cases, it is for appearance. John Oberlies scraped large, non functional areas like Hi Wall breech blocks, levers, hammers, safeties, you name it. It was a beautiful treatment, but largely decorative, not functional. In conversations with posters on this board, no one has seemed to be able to figure out how Oberlies did it.

Yes, that's sort of what I have always figured. It is for form, not so much function with the latter being sort of lamely ascribed to oil-holding capabilities.

If anyone has pictures of a large scraped area, I would love to see them. Scraping a whole breach block can only be for looks as very little of it rides against the receiver and smoothness is not particularly important up to a point.

Remington used to jewel the bolts on factory Model 700's. Not sure if they still do or not. Jeweling or scraping on surfaces that don't make a friction contact is obviously decorative. But on friction surfaces scraping or jeweling is very functional, and works well to reduce surface area and friction.

I would suspect jeweling and this style of 'scrape' finish on the bolt body is for appearance. Aren't these treatments very thin. I'd think if metal surfaces bear against each other the pattern would rub right off.

One maker that regularly uses jeweling is Westley Richards. Over the summer on their blog, they commented about some new four bore locks, and the jist of it was about the effort it took getting the appearance right. The coverage is clearly on non bearing areas. Similar comments about their bolt rifles. It just struck me as a current example of a builder using the effect as part of their embellishment decision, rather than functional.

Steve, wouldn't machine tool ways be scraped to increase the surface area contact?

Ways on machines are scraped for different reasons. Older machines are scraped to bring things back true and remove wear. The type of scraping I was referring to is similar to the bolt pictured in that it is meant to reduce friction.

It doesn't take much depth to reduce friction, and it takes decades of shooting to wear even very minor depth off. I've got an old Rem. 700 varmint rifle that has the jeweled bolt. I haven't a clue how many thousand rounds have gone through it, and the jeweling on the bolt barely shows wear on friction surfaces.

Maybe there is far less actual contact area than you think. The breech bolt on a Pigeon Grade Model 12 Winchester shows contact in a very thin stripe to nothing at all, depending on the particular gun.

Besides the decreased surface area and lubricant retention for friction, a textured surface (by whatever method) would retain oil for rust prevention. Manufacturing metal parts which will make contact with other parts with given tolerances still leaves a lot of guess work of how the pieces will fit and bear against each other in use. If a machinist only textured the area he thought would rub against another in use, the textured area would look strange, thus texture the entire area or part and make it more aesthetic. Imagine how a bolt would look with only the areas that rubbed jeweled.

Besides the decreased surface area and lubricant retention for friction, a textured surface (by whatever method) would retain oil for rust prevention....

Just for me, I'd back up and look at the original bolt picture or another example of a jeweled bolt. There are surfaces that I see that would benefit more from rust prevention than are typically covered.

I could see where reducing the surface area might decrease friction, but I'd think the high points were already well fitted and the dips done in a controlled manner. Less surface area to me would mean quicker wear, and the texturing never seems to be on the surfaces that're designed to bear.

I have seen instructions that generally comment about friction reduction and retaining lube, but then warn about keeping the abrasives away from lugs, cams, sears, pivots, etc. These are only thoughts, maybe I'm biased because I don't care for the appearance overall.

the "less surface area" argument doesn't make much sense to me.

Consider a file.

I think of it as aesthetics and nothing more. But it is interesting to see the different perspectives. I would really like to see more examples of scraping.

Fred, isn't it time to offer up your explanation?

I brought up a Michael Petrov thread that pictures some chasing, both on bearing and non bearing surfaces.

.

Fred, isn't it time to offer up your explanation?

Hi Brent,

With everyone saying it was scraping, I've lost a bit of confidence in

my explanation. I had hoped to do an experiment today, but instead

the day was spent doing home and car repair.

Ok, when I look at the pictures of the bolt, I sometimes think I see dots

and that some of the lines look like overlapping dots. I have a copy of

Clyde Baker's book "Modern Gunsmithing", my edition is copyrighted 1928.

Near the very end of Chapter 19, Engraving and Ornamentation, he talks about using

an "Ark-O-Graph", basically an electropencil and even tells how to make one.

He writes "that by moving the point rapidly over any metal surface it is matted

quickly and without fuss". I hope to try to reproduce this stuff sometime soon.

Fred,

I think what Clyde Baker is talking about will give you a much different surface.

Mike

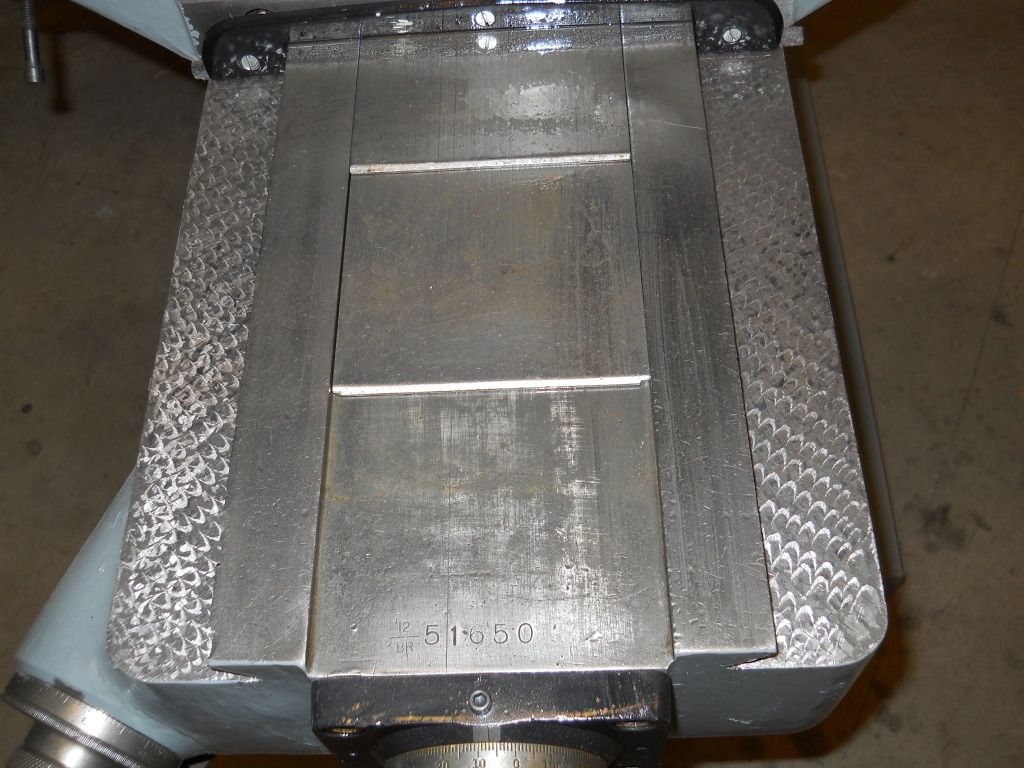

this is the type of scraping I was referring to.

....this is the type of scraping I was referring to.

Steve, that appears to have the tooling marks of scraping, while the original bolt picture looks to be a rotary bit, maybe like rm bill said, a pointed stone.

Can I ask, did you do that? Do you know the whys and what fors of that amount of coverage? Just curious. The machine way scraping I was thinking about just skims high spots on ways and doesn't really show as tooling marks.

Craig,

I did not do that treatment to the metal. It is very common on Bridgeport mills. I believe that surface is done by hand and that the reason is that it reduces friction and gives the lubricant a place to go.

Steve

Thanks Steve. I notice they didn't want to do the dovetails. I suppose, a tiny scraper, good magnification and a really practiced hand could create an interesting effect on a gun part, but I'm not so sure about sort of random looking squiggles. It's probably just me.

The visible pattern on the Bridgeport knee is flaking, not scraping. It is done on the finished surface to aid lubrication and reduce stick/slip. The actual scraping can be seen beneath the flaking, it appears as wider, straight marking.

Scraping is an iterative process on machine tools to produce precision surfaces. Flaking is a secondary operation.

The finish on the bolt in the OP appears to have been done as RM Bill described, for purposes unknown.