Another Drilling to be Identified - Help Welcome - 07/14/10 09:42 PM

Friends,

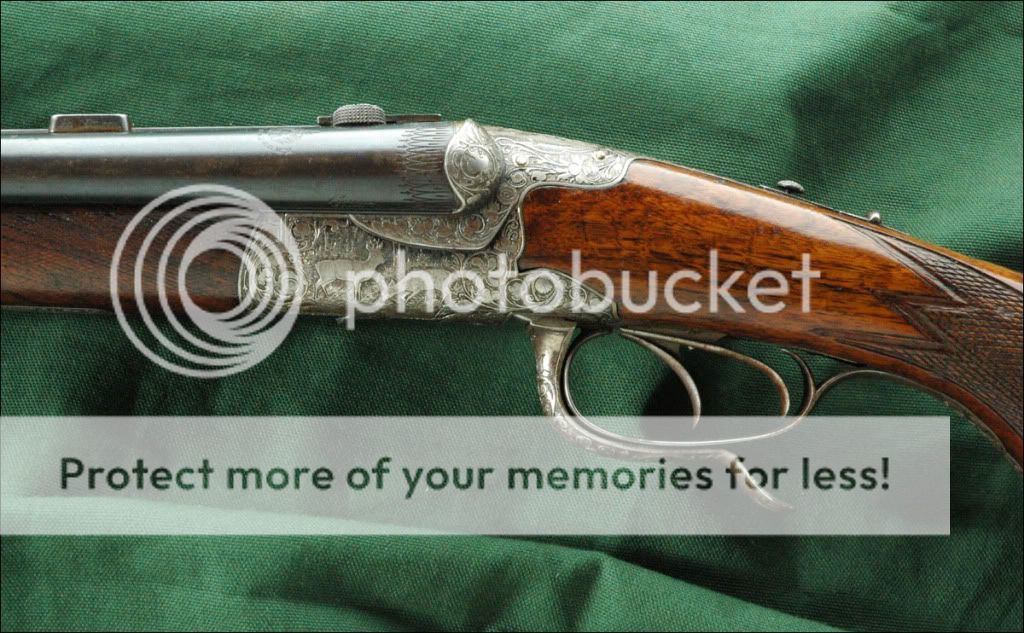

I have another drilling similar to the one I posted all the pictures of in the other thread, only this one is in my opinion, "better".

I do not have photos of it but I have all the details an expert would need to give advice on the gun and to answer the questions I have.

The questions I have are as follows:

1. When was the gun made?

2. Was this gun proofed in Suhl or elsewhere?

3. What can I learn about the maker - A. Strover, Nordhausen (the O in strover has uhmlauts over it)

4. What pressures / types of loads are safe for the rifle?

5. Value? (obviously for that you'll need pictures to be provided at a later date)

6. I was told the gun is a .318 bore 8x57J rimmed cartridge and NOT a .323 bore 8x57JS. I believe this to be true because the gun is so light I would be uncomfortable using the higher power loads. If I do a bore cast and verify it is .318, does this give us any hints to the gun's age?

The facts as dictated by the proofs are as follows:

The shotgun barrels are proofed with the crown over S, W, and U respectively. (also Nitro proofed)

They are proofed with "circle 16" and an additional 16 which I believe is 16 gauge, Full choke for each barrel.

The rifle barrel has crown over N.

The rifle charge is listed as:

StmG

-----

13gr

The cartridge is listed as:

7.8mm

------

57

The two most interesting proofs on the gun that I do not understand are as follows:

-On the belly of the shotgun barrels, an outlined letter M is present on each barrel.

-On the rifle barrel, a fraction stated 1/29 is listed at the very bottom of the barrel near the breech. (could this be manufacturing date?)

-W.K. is stamped to the bottom of rifle barrel which I believe is the initials of the barrel maker.

-Barrels are labeled Krupp Laufstahl

-Serial number is 10402

-Maker or seller's name is found on the top of the barrels (not on the rib). "A. Strover" on one barrel and "Nordhausen" on the other.

-There are numerous duplicate stampings all over the proof area of the eagle shape that was used from 1912 onward.

***Those are all the markings and proofs on the entire gun. I won't be able to add pictures for weeks but that should be enough to describe the gun accurately. It is a Henri Roux type breech that looks nearly IDENTICAL to the other gun I provided photos of with the exception being that this one has a Greener style safety and is in much better condition.

I have another drilling similar to the one I posted all the pictures of in the other thread, only this one is in my opinion, "better".

I do not have photos of it but I have all the details an expert would need to give advice on the gun and to answer the questions I have.

The questions I have are as follows:

1. When was the gun made?

2. Was this gun proofed in Suhl or elsewhere?

3. What can I learn about the maker - A. Strover, Nordhausen (the O in strover has uhmlauts over it)

4. What pressures / types of loads are safe for the rifle?

5. Value? (obviously for that you'll need pictures to be provided at a later date)

6. I was told the gun is a .318 bore 8x57J rimmed cartridge and NOT a .323 bore 8x57JS. I believe this to be true because the gun is so light I would be uncomfortable using the higher power loads. If I do a bore cast and verify it is .318, does this give us any hints to the gun's age?

The facts as dictated by the proofs are as follows:

The shotgun barrels are proofed with the crown over S, W, and U respectively. (also Nitro proofed)

They are proofed with "circle 16" and an additional 16 which I believe is 16 gauge, Full choke for each barrel.

The rifle barrel has crown over N.

The rifle charge is listed as:

StmG

-----

13gr

The cartridge is listed as:

7.8mm

------

57

The two most interesting proofs on the gun that I do not understand are as follows:

-On the belly of the shotgun barrels, an outlined letter M is present on each barrel.

-On the rifle barrel, a fraction stated 1/29 is listed at the very bottom of the barrel near the breech. (could this be manufacturing date?)

-W.K. is stamped to the bottom of rifle barrel which I believe is the initials of the barrel maker.

-Barrels are labeled Krupp Laufstahl

-Serial number is 10402

-Maker or seller's name is found on the top of the barrels (not on the rib). "A. Strover" on one barrel and "Nordhausen" on the other.

-There are numerous duplicate stampings all over the proof area of the eagle shape that was used from 1912 onward.

***Those are all the markings and proofs on the entire gun. I won't be able to add pictures for weeks but that should be enough to describe the gun accurately. It is a Henri Roux type breech that looks nearly IDENTICAL to the other gun I provided photos of with the exception being that this one has a Greener style safety and is in much better condition.