Sometimes things just happen, while all the Black Friday madness was happening, my wife and I decided forgo that drama and hit some antique & second hand shops.

At one of these, I stumbled across a 4 ½ inch Wilton “Bullet” vise, with swivel base. The vise had been well used, and frankly abused, but it worked…. And the price was right $35. Figured that was not too much to spend to satisfy my curiosity on what makes these Wilton vises so special.

A little about the vise: It has C-1 cast in the side of the jaw; a little Google searching: The C-1 is a 4 ½ inch Combo Pipe and Bench Vise (MFG part# 28826), MSC lists it at $1790….ouch !!

I put the 4 ½ inch Wilton next to a 3 1/2 Inch Reed (not quite a fair comparison), for some quick comparisons. I used the 3 ½ because my 4-inch Reed is bolted to a bench, the 3 ½ was just sitting on the shelf.

The Wilton slide is 2.5-inch round tube, the Reed is 2 x 2.5 square. The Wilton has a ½ inch key stock in the slide to keep the ram straight & square.

The Reed has 2 oil holes in order to oil the leadscrew & nut, the Wilton has no provision to oil the screw or nut. This would bother me, as the screw/nut takes quite a bit of friction/stress, I put a squirt of way oil in my vises weekly.

Both the Reed and Wilton have 4 bolt holes to mount the swivel base. The Reeds swivel base is 50% thicker (1.5 inches) than the Wilton (1 Inch), and is heavier by 2 1/2 lbs. (Reed 8 ½ lbs., Wilton 6 lbs.). The mounting flanges are also thicker on the Reed, ¾ vs 5/8 for the Wilton.

The Reed uses a ¾ x 1 1/2-inch shoulder bolt in the center to secure the vise to the swivel base and to provide a pivot for swiveling, the clamping nut just keeps the vise from turning.

The Wilton uses a small ½ inch dia x ½ inch long pin as a swivel point, it relies on 2 modified ½ carriage bolts to both secure the vise to the base and to keep the vise from turning.

The Reed utilizes a toothed cam style to securely keep the vise from rotating, teeth engage corresponding teeth in the swivel base, ½-3/4 turn to positively lock in place.

The Wilton relies on 2 modified carriage bolts, but instead of a positive cam locking system, it’s based on friction to keep the vise from turning, a lot of the imported low cost vises utilize this system.

Initial impression is that the Wilton’s swivel base is definitely a weak point, it has less mass, Most of the swivel base has been machined away, and adding insult to injury, it relies on friction (clamping force) to stop the vises rotation, if the operator cranks down on these bolts, it puts a tremendous amount of force on a very thin area of the swivel base. It also relies on these bolts to hold the vise to the base. If that base cracks there aint nothing holding that vise on.

As I get more into the disassembly of the Wilton, I’ll post more… lead screw size etc.

That was a good buy, if the abuse wasn’t too substantial.

Best,

Ted

That was a good buy, if the abuse wasn’t too substantial.

Best,

Ted

And a good report, Mike. Thanks.

SRH

Ok, now that I’ve had a chance to partially disassemble:

Wilton dated their vises, this one is dated 3-47 so, fairly early for a Wilton (Wilton started building vises in 41).

The vise is definitely cast not forged, lots of casting lines; the ram and movable were cast as one piece.

Metal thickness on the tubular ram is .400, I was somewhat surprised that the moveable jaw is not solid, but hollow about the bottom 2/3. The best that I can tell, the fixed jaw is solid.

Reed vises I believe were forged, and have solid moveable jaws.

The lead screw measures .860, so pretty good size. Also surprising is the nut, it’s about 6 inches long. Longest nut I’ve seen on any vise. Probably designed to never wear out, as it would be a royal PITA to replace it.

Most other vise manufactures treated the nut as a sacrificial part, easily replaced.

So anyway, a good oiling and greasing of the lead screw, it’s back together. I’ve got to replace the jaw inserts, they are pretty beat, and gonna drill a small oil hole in the ram so I can squirt oil on that leadscrew occasionally.

My take is that there is nothing "magical" about a Wilton Bullet vise, and some components are actually built weaker/cheaper than other period vises. The shape is fairly novel as is the round ram. But a $1700 vise it isn't..at least not in my mind.

For those looking for a decent gunsmith bench vise, take a good look at the Reeds, Parker's, Rock Island etc. The Wilton are good, but not worth the premium.

Pictures?

This one is my 6" that I have used for 50 years

in my reloading room

The nut on your Wilton is easily serviced, easily replaced, and, available new, to this day:

https://www.ereplacementparts.com/vice-nut-p-729439.htmlDo yourself a huge favor. Clean it up, wipe the seal on the bar down, put a gob of Mobile 1 Universal synthetic grease on the nut, and the screw, put it together and forget about drilling anything or lubricating it, ever again.

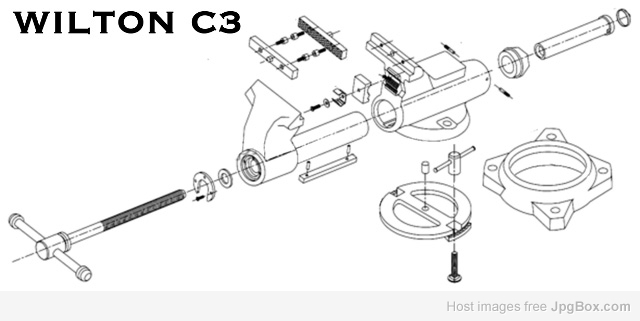

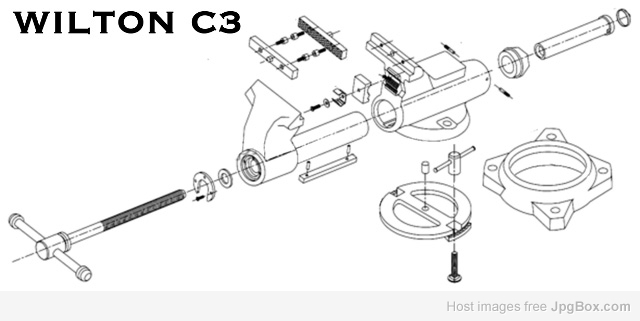

Generic exploded view of a Wilton bullet:

Where does all the oil you squirt on your other vises end up over the years?

There are forged steel vises out there, but, they are not Reeds.

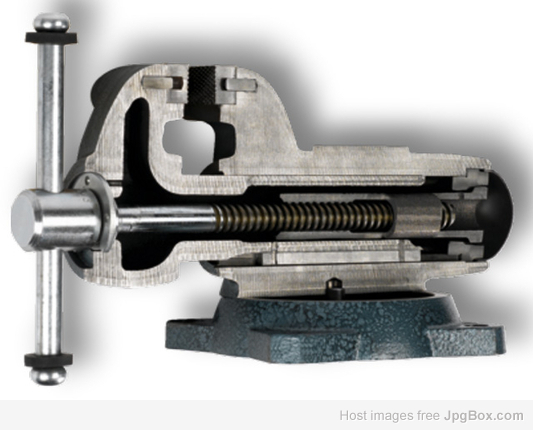

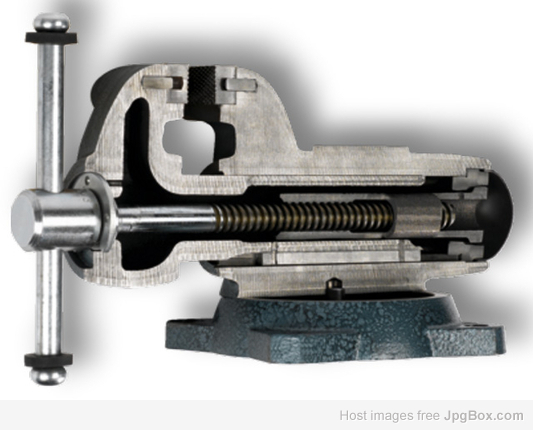

Another image. Pictures are worth a thousand words:

Just curious, is this the style of lock on the Reed you are talking about?

Best,

Ted

I oil the leadscrews on my vises just like I oil the leadscrews on my mills, lathes, etc. it’s a loss system, but keeps fresh oil there. Wipe up excess with a rag.

Couple of reasons I don’t use grease much at all in the shop:

Grease mixed with dirt, grit, chips, swarf etc.… makes a wonderful lapping compound. That’s why one should never use grease on mills, lathes, surface grinders, even though they have felt/neoprene wipes, stuff will get in there and quickly ruin your machine. Oil on the other hand, does a great job of flushing out the crap, and lubricating.

Grease is an emulsion of oil for lubrication and binders/thickeners/plasticizers. Generally, grease has a working/shelf life of 1-2 years before the oil either evaporates or separates out. We’ve all dealt with old hardened grease, that’s the stuff left over after all the oil has gone, very little lubricating qualities.

Ted, Thanks for posting the Wilton exploded diagram, as they say “a picture is worth a thousand words”.

At the back of the vise there are two pins, those hold the nut in place.

As far as the nut, “easily replaceable” is a relative term; most conventional vises, all you do is remove the moveable jaw/ram assembly by unscrewing, loosen the small set screw on the back of the nut and slide the nut out.

Looking on the web, those pins are not thru pins, and need to be removed by backing them out, lots of discussion about making special tool for their removal, and some have had to resort to drilling them out.

Great pic of the swivel lock, that pic next to the beer can gives a good idea of size, on my 4-inch reed, that bolt is ¾ inch. So, a good size bolt. It also shows that a ham-fisted workman can break an anvil with enough force.

Unfortunately, you didn’t show the caming teeth on the other side, that engage corresponding teeth in the base, this provides a significant amount of holding power with light hand tightening. Full swivel to full lock is one revolution.

As the picture shows, the wilton vise relies on friction to keep the vise from swiveling, think two plates sliding against each other, the only way to get it tight is by clamping harder, that’s a lot of force on that ring which is less than ½ inch thick cast iron. It's also the reason that Wilton uses two bolts, while vises utilizing the caming system only need one.

That cut away of the Wilton vise confirms my examination of mine, the moveable jaw is mostly hollow, while the fixed jaw is solid; wonder why they did it that way, would like t have seen them both solid.

Respectfully

Mike

Mike,

What is stronger, solid round, or tube?

I think the beauty of the friction system comes when it is designed to let go at a level that protects the components of the vise. And, that can be done, but, it assumes someone won’t put a cheater on the hold down bolts. Having the vise locked, mechanically, might seem like a good idea, until Bubba shows up. For some reason, Bubba has been around most of the used vises I have looked at.

The modern, synthetic greases run far longer than old, white, lithium. The Wilton’s are sealed far better than any other vise I have had a chance to look at, keeping whatever is in the air out of the lead screw. Not sure if your fairly old Wilton example has the rubber seals in it, as the newer Wilton’s do. But, the lead screw stays remarkably free of whatever I happen to be putting in the air and on the bench in the shop on my example. You can make dandy valve grinding compound out of either oil or grease, but, if either is sealed away from the grit right to begin with, you are ahead of the game.

Up your grease game:

https://www.exxonmobil.com/en/aviation/products-and-services/Products/Mobilgrease-28I like the shelf life and the useful temperature spread on all the Mobile synthetic products.

Probably comes down to personal preference at the point where you are debating merits of two, big, high quality vises. There is more than one way to compress and remove valves from the head of an engine, but, I still use a Blue Point tool that is early 1950s vintage for that task. The old tool works, and, as long as it does, there is no need for me to replace it. Couple people have asked if they could buy it.

But then I’d have to find another.

Let’s see the Wilton when you get it all cleaned up.

Best,

Ted

This Wilton "bullet" vice was my dads and I have had it for 50 years. The jaw width is 3 1/2" and they are hardened. It weighs 37 lbs. I have used it for everything, wood working to filing a straight line with it flush to the jaws. It is mounted now on a 5/8" plywood base that I can secure to my wood working bench using bench holdfasts to hold it secure.

[img]

https://i.imgur.com/6w3i8Td.jpg?1[/img]

[img]

https://i.imgur.com/UnYRDQj.jpg?1[/img]

Mike,

What is stronger, solid round, or tube?

Best,

Ted

Ted… Seriously?

Quick science experiment, take a can of Coke, empty it, now stand it up it on a hard surface and step on it. Then repeat the test with a 2 ¼ inch x 4 inch solid round aluminum bar. Which one failed quicker?

HAHAHA!!!!

Cherry pick your testing procedure much?

Seriously, when side loaded, which will deflect or bend, tube or solid, and which will break without either happening, assuming equivalent dimension, material, and force applied?

I also want to throw out the fact that almost all of the Wilton’s were built of nodular iron, and few of the Reeds were. That said, when I see a broken vise, it is never the mobile jaw that is broken. A lot of things probably break on the way to the jaw breaking, and you are long into abusing the tool at that point.

You brought up the jaw is hollow on the Wilton. I’m going to guess the engineer knew how much strength he needed there, knew the limits of the material he was using, knew he wanted the vise hollow there for one reason or another, likely related to manufacturing, and tested until he had a profile that got him what he wanted. And then went on to produce them for 75 + years, right up to today.

Are there bunches of broken mobile Wilton jaws out there? You bring up a fair point, but, observation doesn’t seem to validate it.

Best,

Ted

Looks like the Wilton vise was born out of WWII

I suspect that the other vise makers, with more mature casting, forging, and machining capabilities focused on the war effort; just like Chrysler making tanks, Ford making bombers, Singer – guns etc.

Wilton’s first and only customer from 1941-1945 was the U.S. Government, and we all know how the Government loves the lowest bidder. :)

Yea, the Manhattan project is a great example of WWII bids going to the lowest contractor.

It takes a lot to win a war, but, losing takes everything.

Best,

Ted

Ted,

The Manhattan project wasn't a contract, it was a US Army Corps of Engineers operation, the Manhattan District( named to hide the purpose) Engineer was MG Leslie Groves.

Mike

It wasn’t lowest bid, either. It was the most expensive human endeavor in history to that point in time. I thought it best to approach Mike’s comment with humor.

Mike painted with a wide brush when he made the comment about government, lowest bidder, WWII, and companies who only had the government as a customer for four years. Many, many companies produced no consumer goods during those four years. Wilton was a new company, and likely was told everything they could produce was spoken for, until the war ended. While times likely were as good as they could be, during the war, it is a known fact that the government sold much of what Wilton had produced for pennies on the dollar after the war, and nearly destroyed the Wilton company.

Lay down with dogs, get up with fleas. The biggest dogs are in government.

https://www.wiltontools.com/us/en/company/history/Best,

Ted

I figured the front of it would be solid....anything to save a few bucks.

I figured the front of it would be solid....anything to save a few bucks.

Probably doesn't matter if you are dealing with a guy who can and did break a vise....

Best,

Ted

Best,

Ted

You be drinking too much Ted....

I bet the most fabrication yer Wilton has witnessed is crushing beer cans.

Mike,

What is stronger, solid round, or tube?

Best,

Ted

Ted… Seriously?

Quick science experiment, take a can of Coke, empty it, now stand it up it on a hard surface and step on it. Then repeat the test with a 2 ¼ inch x 4 inch solid round aluminum bar. Which one failed quicker?

I think yOu got him there Mike.

Joe

My intent was not to “get him” or disparage Wilton vises;

Some consider Wilton to be the gold standard of vises, my intent was to provide a fairly honest assessment of Wilton’s “Bullet” vise.

All vises have inherent strengths and weaknesses, Wilton’s are no exception.

All said and done, all vises are just simple mechanisms designed for work holding...

Respectfully

Mike