First, you're all welcome. I knew that engineering degree would come in handy one day.

Now, on to the other points. I think most of what's been said on the thread is correct, so please note I'm

not going after anyone. I am disagreeing in some aspects and giving my reasons.

Chuck, you said:

While I think I understand why you stated " Banging out the dent or bulge can reshape the metal to the original, desired shape, but it does not restore the strength.", I would temper that statement with a more so we don't alarm people unnecessarily about dents and their removal/raising.

The point is, and I think I should have been clearer in the beginning, that once metal is stressed past the yield point into plastic deformation, there are stresses introduced into the metal which are permanently there (and can only be removed by annealing). Reshaping the metal (banging out the dent) is merely adding more plastic deformation to that which got us into the problem in the first place. You are correct that raising dents in barrels is not something to lead them to be alarmed unneccessarily. But they should be concerned nonetheless.

This is because the plastic deformation manifesting as damage to a shotgun barrel happens under uncontrolled conditions. The conditions of starting and ending temperatures, the amount of force and rate, vectors and sharpness of the object(s) imparting the force, and every other thing acting upon the barrels are neither controlled nor recorded. So, any claim to a scientifically precise approach to determining the risk from a dent and from dent removal is pretense.

You continue:

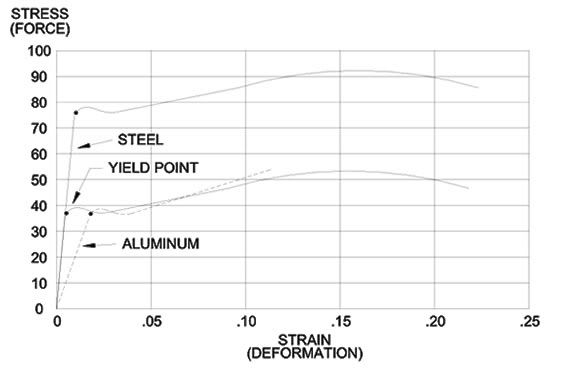

As can be seen in the diagram, any deformation beyond the dip (yield point) results in higher stress required to further deform it. In the example, this higher stress is around 20-22% or so. But all deformation (aka elongation) beyond the yield point results in "necking" (thinning) of the test coupon, yet it still took 20-22% more force before necking reduced the cross section enough to have a negative effect on the strength of the coupon.

All true. But, it elides the problem. Because the plastic deformation manifesting as damage happened in uncontrolled (and un-measured) conditions, we have no way at all of knowing where on the stress-strain diagram the barrel currently lies. We'd have a better chance of being accurate if we were throwing a dart at the diagram. That understates the problem because it's entirely possible that different parts of the dent are at different points on the stress-strain diagram. Again, that's because the conditions under which the damage took place were uncontrolled and un-measured.

You continue:

This shows that even though the metal continued to get thinner as it stretched, it still got stronger up to the crest of the curve where the reduction in cross section (thinning) was so much that it affected load carrying capability of the metal. If we knew what amount of stretching has occurred in the metal, we can use a chart like this to evaluate whether we are near a fracture. We can also measure wall thickness and compare to see if the barrel is weaker due to thinning or if the net effect is insignificant.

Again, true, but also unhelpful. That increase in strength that took place as plastic deformation continued is work-hardening, which is accompanied by an increase in brittleness. So, while the metal may be stronger, it will also be more brittle and break unpredictably. Thus, banging out the dent will both strengthen the metal and make it more brittle. And, as noted above, given the uncontrolled conditions we cannot know the amount of stretching which occurred in the metal and more importantly, how. Measuring the remaining barrel thickness can give a rough index of whether there is sufficient metal and, derivatively, non-brittle strength, remaining. It needs be remembered that, contrary to some uses, the loads applied to shotgun barrels (by firing) are sudden, sharp impulses, i.e., the very kind of stress application that intuition tells us is most likely to shatter something brittle.

You continue:

Also, that portion of the diagram from the yield point to the failure is the basis of why hammer forging barrels makes them stronger. As you can see it also requires close control of the process.

Also quite true. It's the controlled process which distinguishes the plastic deformation that goes on in hammer-forging from denting shotgun barrels and banging out the dent. Moreover, and please correct me if I'm wrong, but I recall that in hammer-forging gunbarrels there are any number of annealing and tempering stages to relieve the internal stresses caused by the hammer-forging. I think if a gunsmith who was going to bang out that dented barrel was to take a torch to it too, he'd likely get a response like that received by the re-colored Parker and the gunsmith/gunseller the other week. The torch-wielding gunsmith might be doing exactly the right thing - trying to relieve stress in the metal - but I wonder who here would go along with him.

I agree that under closely controlled conditions, predetermined and designed by skilled engineers and scientists, plastic deformation is a useful tool in making metal stronger. I also agree that it's entirely possible to dent and later remove dents from shotgun barrels and have them remain safe to use. But the latter do not take place under the controlled conditions of the former and, consequently, caution must be exercised. How much risk of failure remains after a repair is almost impossible to determine and people are notoriously bad judges of risk/probability anyway (One is far more likely to be hit by lightning than win the big prize in the lotto, yet we come in out of thunderstorms and line up at the lotto terminals.). And, even in the most stringent settings, failure may come never, decades from now or, as in the case of Ballistix' pretty 20 ga, 2 weeks after passing proof.

So, using a gun with repaired barrels is an undefined and undefinable risk, and only the user can decide whether it's too much of a risk to accept.