Many fine guns have barrels made of chopper lump, dove tail or demiblock construction. For example, many English guns such as Purdey are of chopper lump. Some American guns such as Winchester 21 are similar to chopper lump, but use a dove tail method. Browning superposed are of demiblock construction. These methods are all very similar and differ from monoblock construction in that with monoblock there is a weld point just anterior to the chamber where barrels are joined to the monoblock. Examples of this sort of construction are many such as beretta, browning citori and Perazzi just to name a few. Certainly, no one would argue that monoblock is a much cheaper method than the others. Sometimes however, cheaper methods can be better. Which methods do you consider better in terms of strength and safety?

About equal in all respects, I'd say

Mike

I really have come to not like the Beretta & others way of making the joint line on Mono construction so very visible,with a ring of "engraving".I would of thought they would be able to do a "seamless" job?

Franc

For a side by side ,choppres are certainly the strongest and with modern production methods on prodution guns I can not see that there sould be any difference in cost .The tubes themself will cost more to produce but this would be compensated for in the,reduction of cost in the assembly,due the the methods used, Cheap Spanish guns are good example . This is not to be confused with hand build barrels for high grade guns . As far as O/U's go ,using a mono block that can be precsision cast will cut machining time down thus reducing the overall cost to the customer. Up untill now there has been very little trouble with mono block barrels ,considering the number that have been produced.They are also expected to stand up to much heavier loads and to more prolonged useage than guns of an earlier generation .But then again manufactureres are not expecting these guns to last for a century.It is not in there interest to do so.

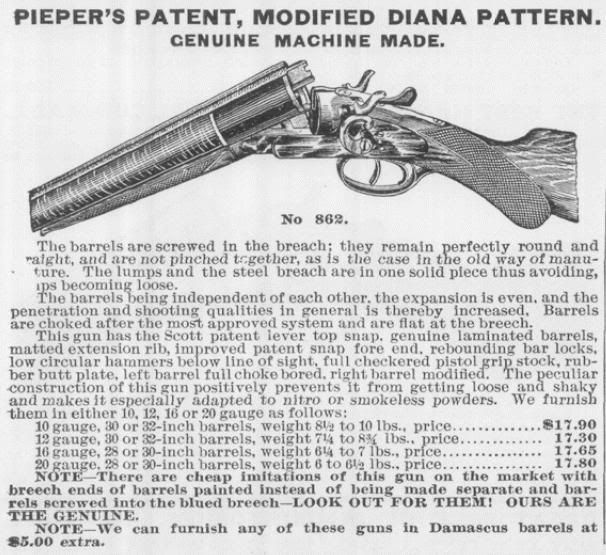

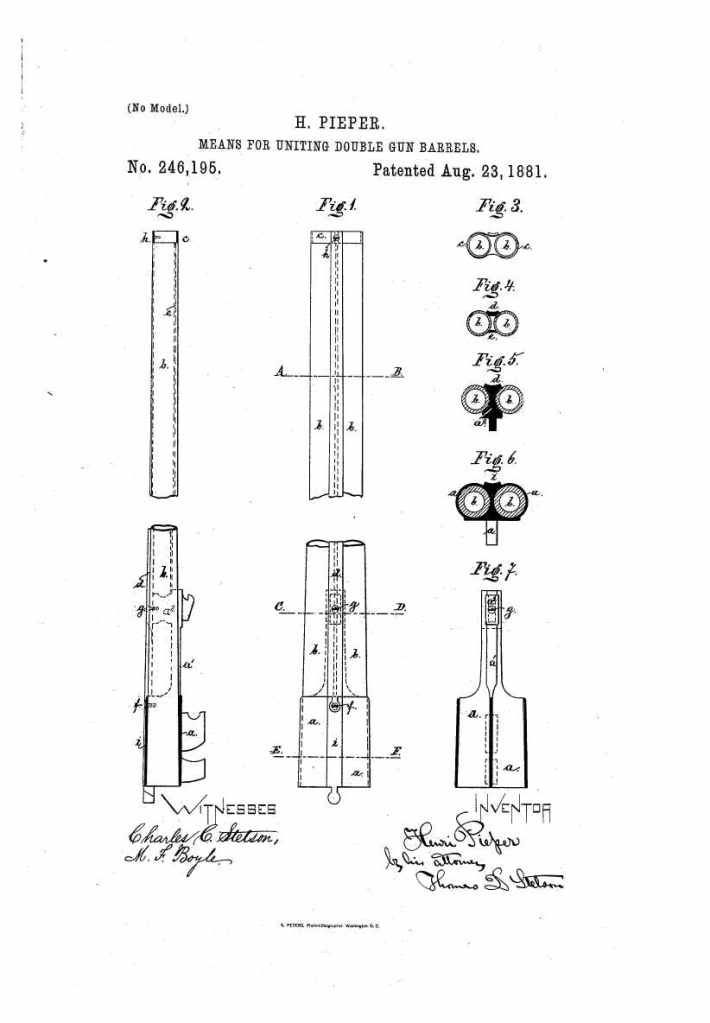

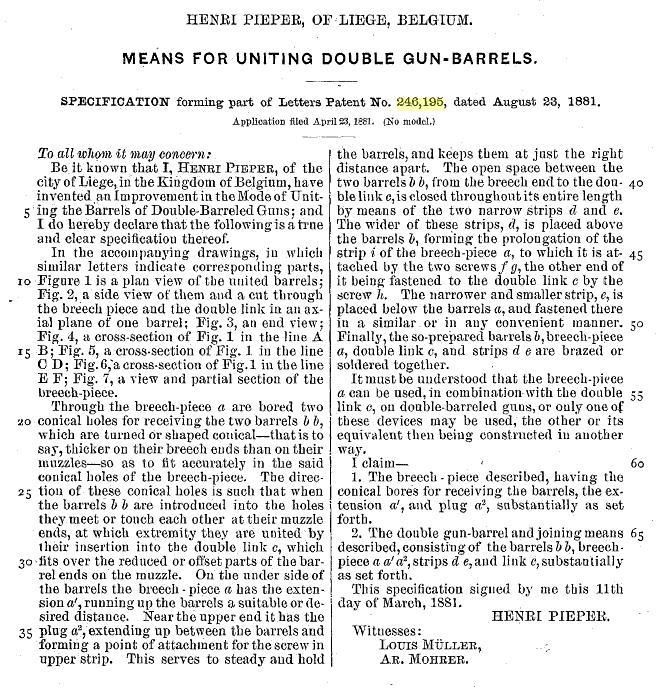

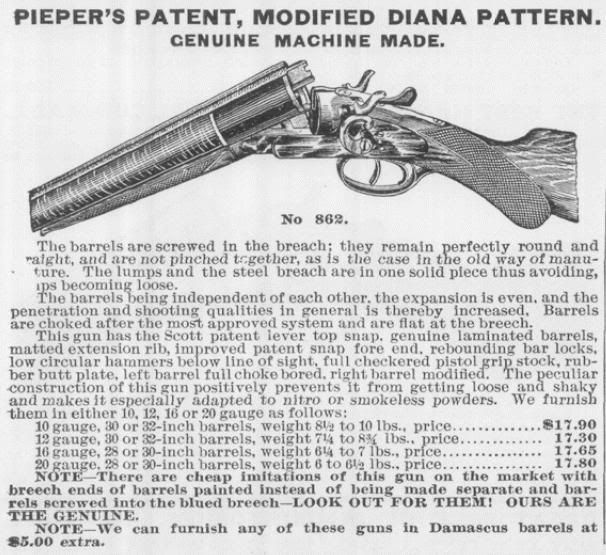

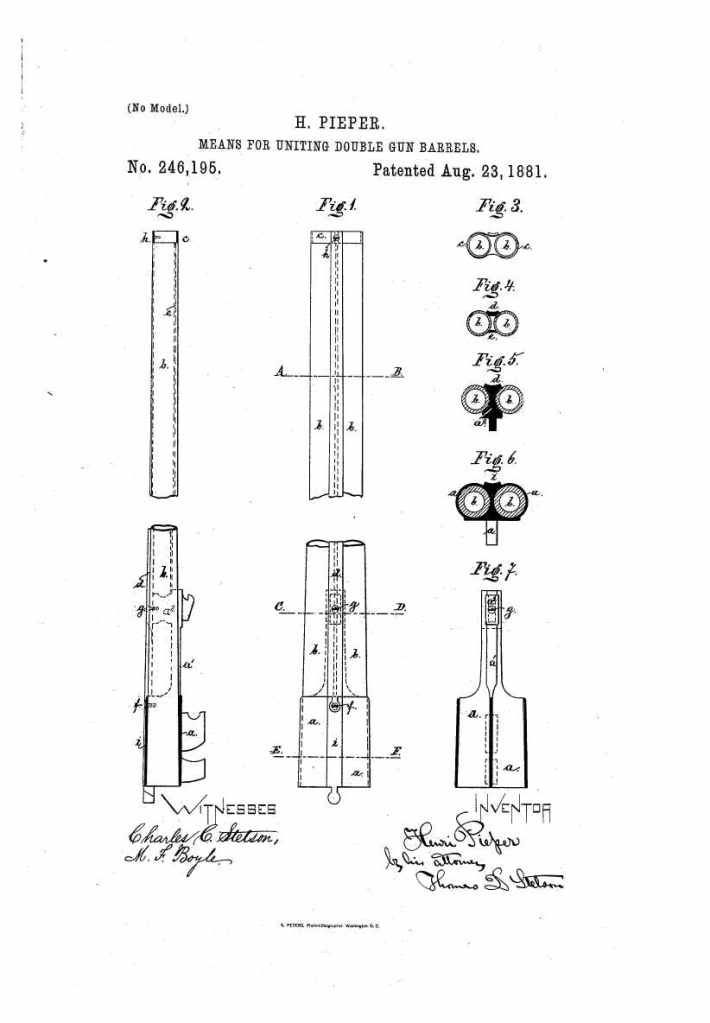

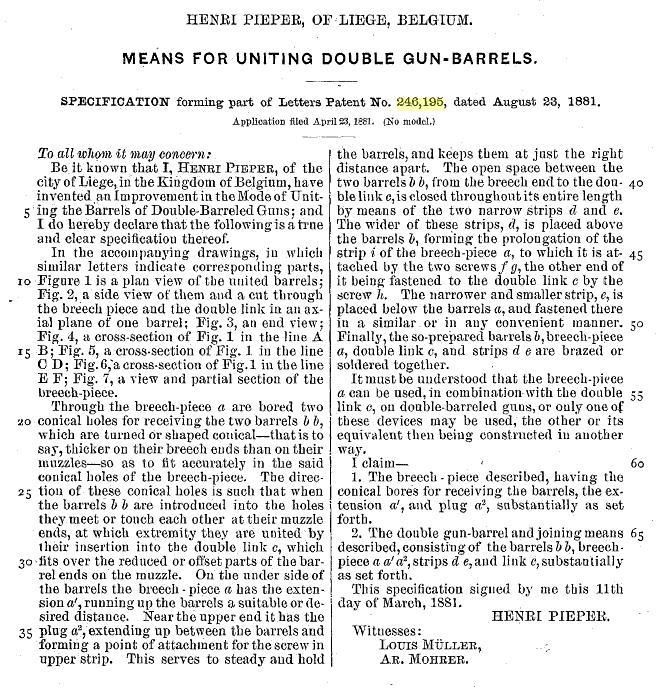

Pieper invented the Monobloc, 1881. The barrels were screwed into the breech. His patent required a band on the muzzles.

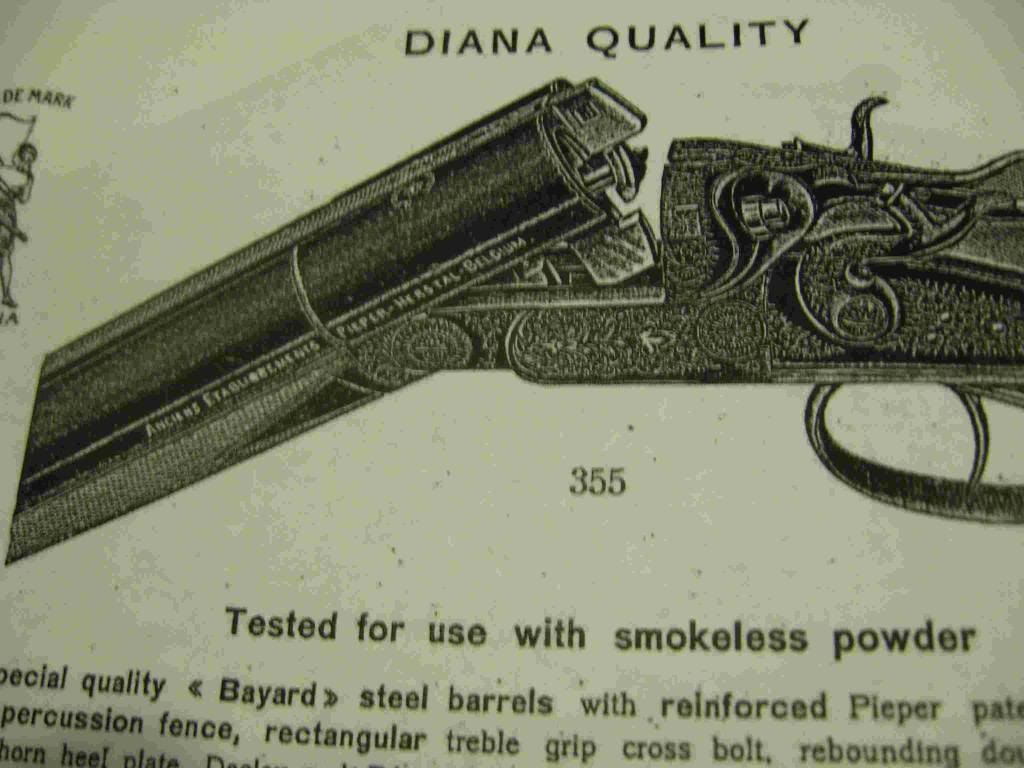

His company moved to the demibloc after his death. I believe at the time, it was the cheaper method. So, by 1900 the demibloc was in use by Pieper.

Beretta adopted the monobloc in 1913, if Wilson is correct. I know there no Beretta guns that use it in a 1910 catalog. Another early user was Darne.

http://damascus-barrels.com/uspatentnom.htmlhttp://www.google.com/patents?id=QiBMAAA...p;q&f=falseSears 1897 catalog.

In this 1932 Beretta catalog, the M1010 is clearly a monobloc.

This is a 1938 Beretta catalog. It appears the barrels are soldered or brazed.

This is not a monobloc, but you get the idea.

Personally, I only care that it has passed proof.

Pete

In Pieper's original patent the bbls were not threaded in to the breech piece (mono-block). The breech piece had tapered holes through it & the bbls were inserted from the rear & seated in the tapers. There was thus a step down at the forward end of the breech piece, or what we generally refer to today as "Fretted". The tubes being turned down & threaded in to the breech piece & giving a smooth joint came at some later point. I do not know who, but suspect someone patented this method.

One of the big "Bragging Points" of the mono-block was it did not require brazing heat to assemble, but was a combination of mechanicl & soft solder, but had far greater strength than a normal assembly would if done with only soft solder. Conventional, Dovetail, Chopper & Shoe lumps all require brazing heats for maximum joint strength. The dovetail chopper lump as on the M21 & some others does not require brazing as the two are mechanically held together & pinned to prevent shifting. They can thus be soft soldered to complete the joint with no fear of bbl seperation.

Note that all of this has only to do with the strength of the connection between the two bbls & does not pertain to strength as regards to handling pressure of firing nor the connection of ribs etc.

Pieper did use a band at the muzzle in his oroginal patent, to say it was a "Requirement" is I think stretching the point. The Pieper hammer gun I have built with the later method of screwing in the bbls does not have a muzzle band. Also on mine the bbls have short stubs which extend only about half way through the breech piece, not all the way as on those pictured. He seems to have used several methods over the years. Mine is marked Modified Dianna.

A 1911 "Alfa" catalog still lists Pieper guns made on the mono-block principal, though they are simply referrd to as having a one-piece steel breech piece. I so far have never seen a reference to Pieper using the term mono-block.

The patent specifies link

C. So if it part of the patent there is no stretching.

The double gun-barrel and joining means as described, consisting of the barrels b1, b2, breechpiece a, a1, a2,strips d e, and link c, substantially as set forth.

Certainly they kept changing the methods after Henri Pieper's death. If they modified the patent when their methods changed as would be usual, I can not tell.

Neither his patent nor the documents he submitted in Paris specify how the tubes are held in place.

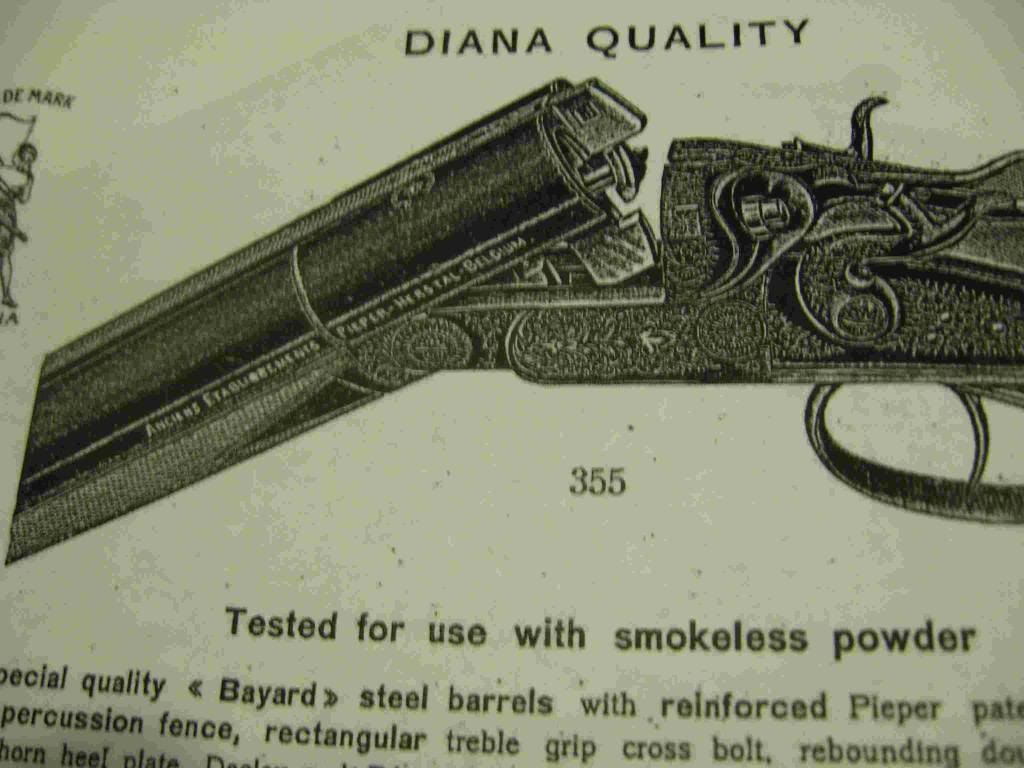

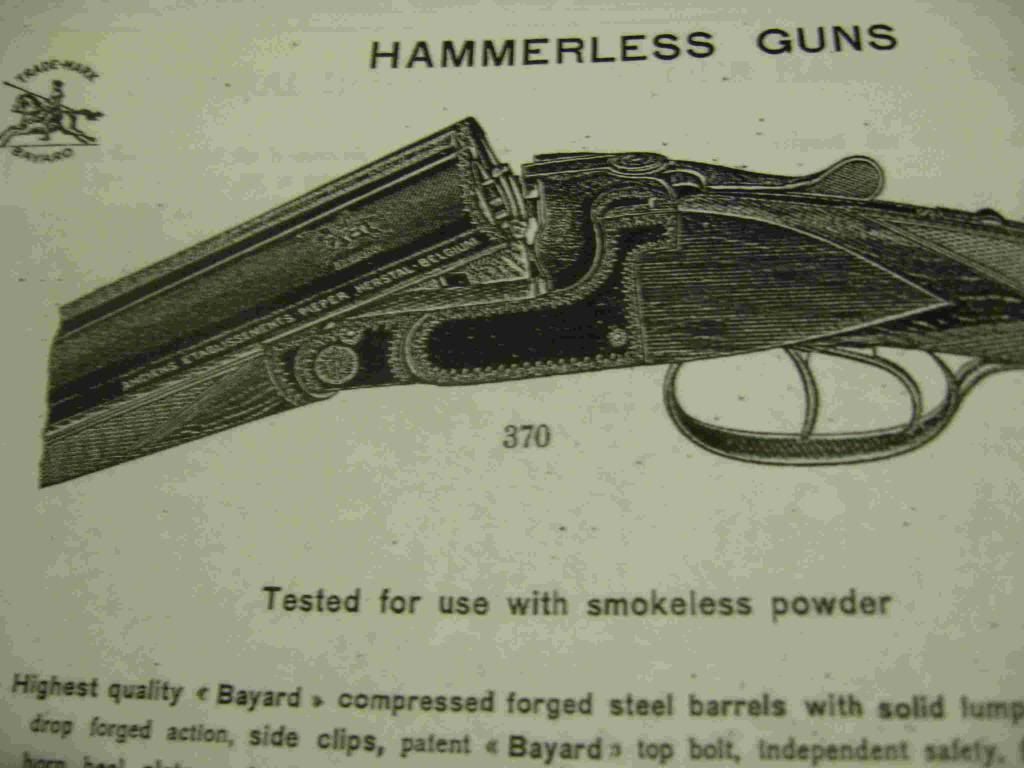

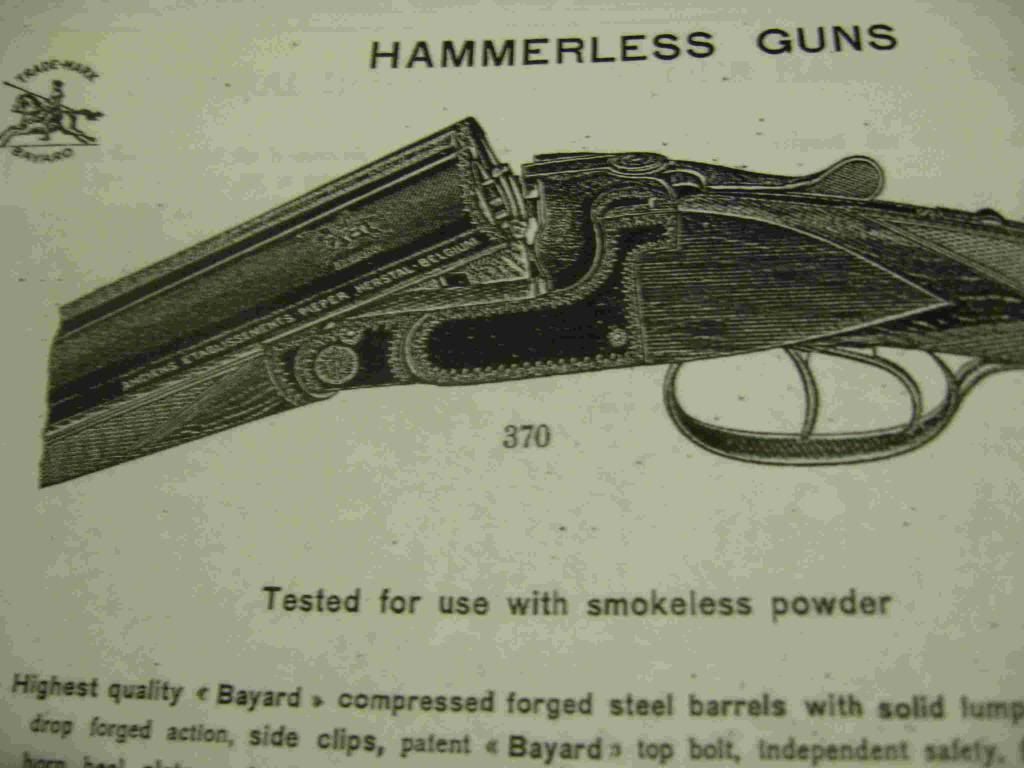

Here are two images from a Société Anonyme Anciens Pieper Establissments (AEP) 1911 catalog

Long after his death, the company is still producing the Diana, the 1881 patent, monobloc

As well as this demibloc model.

I own a Diana (c 1883), a Modified Diana (c 1895), a later demibloc (1925) and a very late (1947) demibloc. When he was alive, Henri Pieper was a bit of a tinker. He was constantly experimenting with means to cut out steps and increase the automation of his factory.

Pete

This is all extremely interesting to me. I was very unaware that monoblock has been around since the late 1800's. The Beretta Monoblock almost appears like that of modern day 'sleeving'. Is there any difference?

Would someone please describe the differences between chopper lump and demi-bloc construction in S x S guns? I thought they were different terminologies for the same thing.

Mr. Miller: You are amazing. There is hardly a subject that comes up that you cannot contribute to in a meaningful way. I am printing your input on this subject and putting it in the file. And Pete from Illinois, your stuff is always interesting too. Thank you both!

The late British gun guru (and engineer) Gough Thomas thought highly of "fretted" barrels. From his "Gun Book":

"With resleeving now thoroughly established, it seems remarkable that no British firm has adopted the fretted barrel, with its possibilities for combining greater strength with a reduction in the cost of producing double guns." He continues the subject for a long paragraph.

Manufrance also used fretted barrels, going back quite some time. Most of their "Robust" guns have the very visible "step" between the monobloc and the tubes. In fact, at least in the States, if you see a gun with that "step", I'd say there's at least a 90% chance that it's a Robust.

The pictures of Henri Pieper's patent of his method of joining bbls is his US patent. Said patent was issued Aug 23, 1881 as US patent #246,195. This patent can be viewed here;

http://www.pat2pdf.org/patents/pat246195.pdfA reading of this patent quite well describes the method of joining. The breech piece & bbls were stated to be turned with mating conical tapers & were further joined by either brazing or soldering. There were no threads in this patent. This did give the "Fretted" assembly.

Miller,

I do enjoy our exchanges. Reminds me of many years ago on the board. The back and forth about patents vs seen examples.

I have been exchanging emails with an international patent attorney based in Europe. He has helped educate me a bit. Seems there were different standards that various countries used regarding intellectual property. In Belgium, "patents by work" and "trade marks by first use in commerce" were the norm. While in the US, changes in method required a new patent to be filed to amend previous patents, this was apparently not the case in Belgium. I don't even pretend to understand all this. If there is a patent attorney reading this, HELP!

It all started when I mentioned the "Paris Convention for the Protection of Industrial Property of 1883".

Gil, thanks.

Buzz, most of what we see today came about by trying to invent the "better mouse trap". Do a search on Google patents for "mouse trap", you will be amazed....

Any how, that is why I put together that patent compendium, as Daryl calls it, for US patents. I am working on a similar one for British patents. Any one care to work on a French or German patent compendium?

http://damascus-barrels.com/uspatentnom.htmlWild Skies,

Here is an excellent site for such things.

http://www.hallowellco.com/abbrevia.htmBe sure to check out the photos for each definition.

Pete

Pete

I've never seen any posting or firsthand account of where any of these various designs failed where a different design would have held together.

Chuck H, I had a Wm. Powell & Son .410 back-action hammergun built in 1886 with drop in lumps that failed...I doubt very much that would have happened had they been chopper lump.

Thank you PeteM for posting that link confirming that chopper lump and Demi-bloc construction are different terminologies for the same thing.

Wild Skies, can you describe the failure ? Was it a converted rifle ? Pretty early for a 410.

The Browning Superposed was originally made with monoblock construction. After the first 1200-1500 guns FN changed to the later style in about 1932. I am unaware of any history on the reason for the change, but the speculation is that it may have been to allow guns to be built more quickly. I believe the monobloc guns have functioned well.

Contrary to what Hallowell says, the demi-bloc (as originally defined by Pieper) is not the same thing as chopper lump. The demi-bloc is a special case of chopper lump - it is a chopper lump in which the two lumps are joined by use of a dovetail. NOTE: That is not the same thing as dovetailed lumps, in which the lumps are attached to the barrels by use of dovetails.

McIntosh discussed the difference between chopper lumps and demi-bloc in his discussion of the Winchester 21 in "Best Guns".

I used to own (wish I still did!) a pretty little Pieper demi-block 28 ga hammer gun. Upon close examination, it did in fact have chopper lumps, and the lumps were joined to each other by a vertical dovetail. The dovetail joint was almost invisible, but I was able to find it with some difficulty.

Jim Cassada, aka Seamus O'Caiside

Pete;

Thanks for posting page two of the 1881 patent. As I have no reference to an earlier one I am taking this as his original patent. From both the illustrations & the description it is obvious this patent did not describe the bbls being threaded in. As to whether this patent was sufficient to protect against a gun being fitted with a one piece breechpiece with bbls joined by some other method in Blgium I do not know.

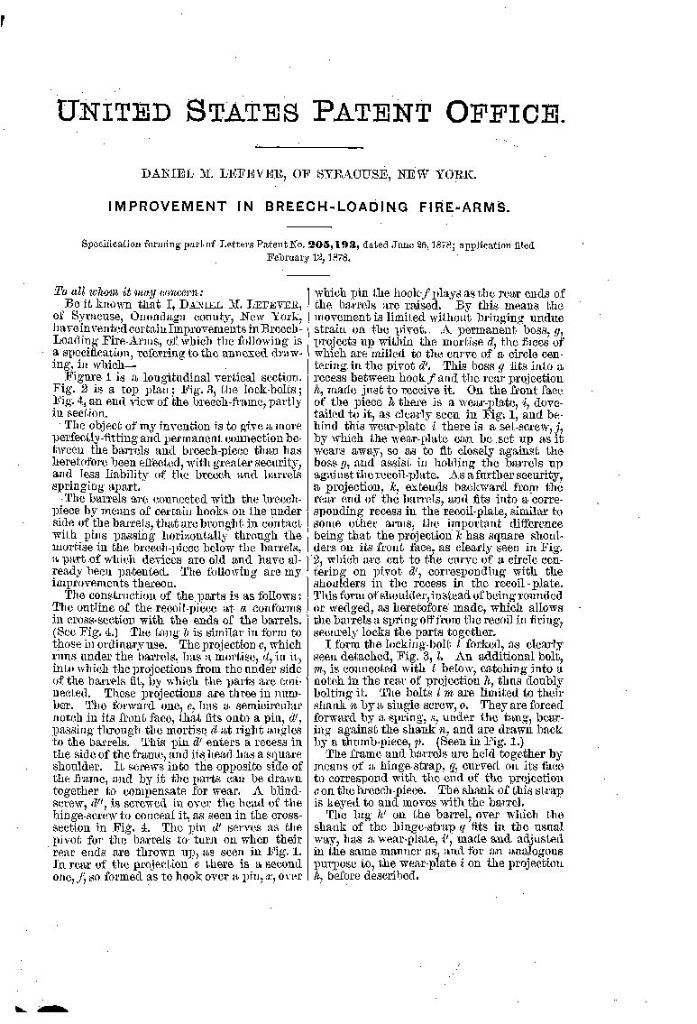

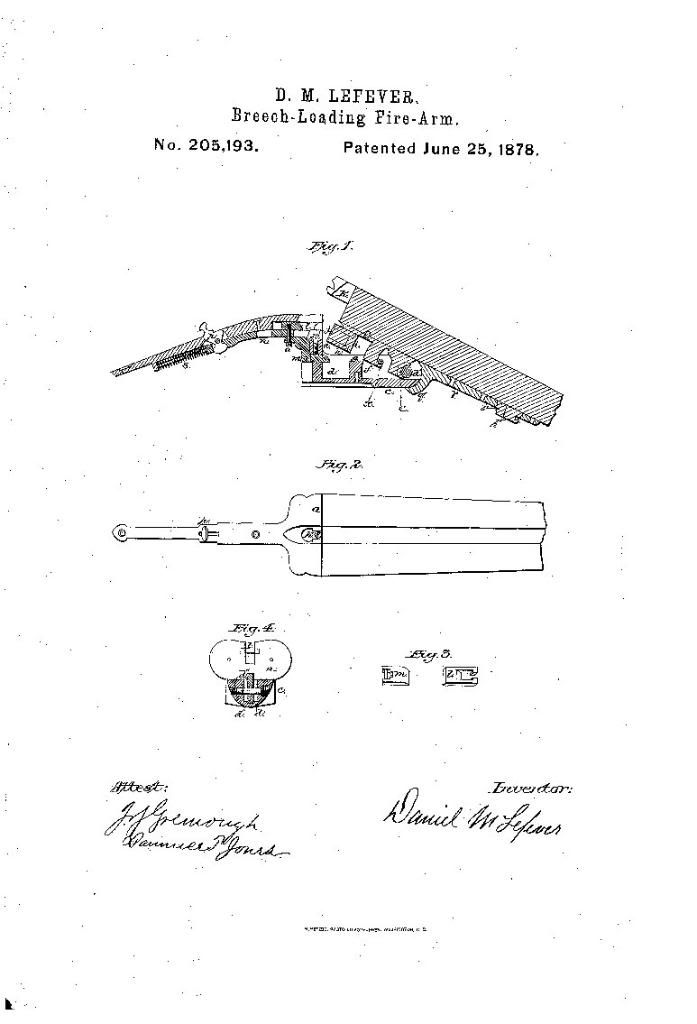

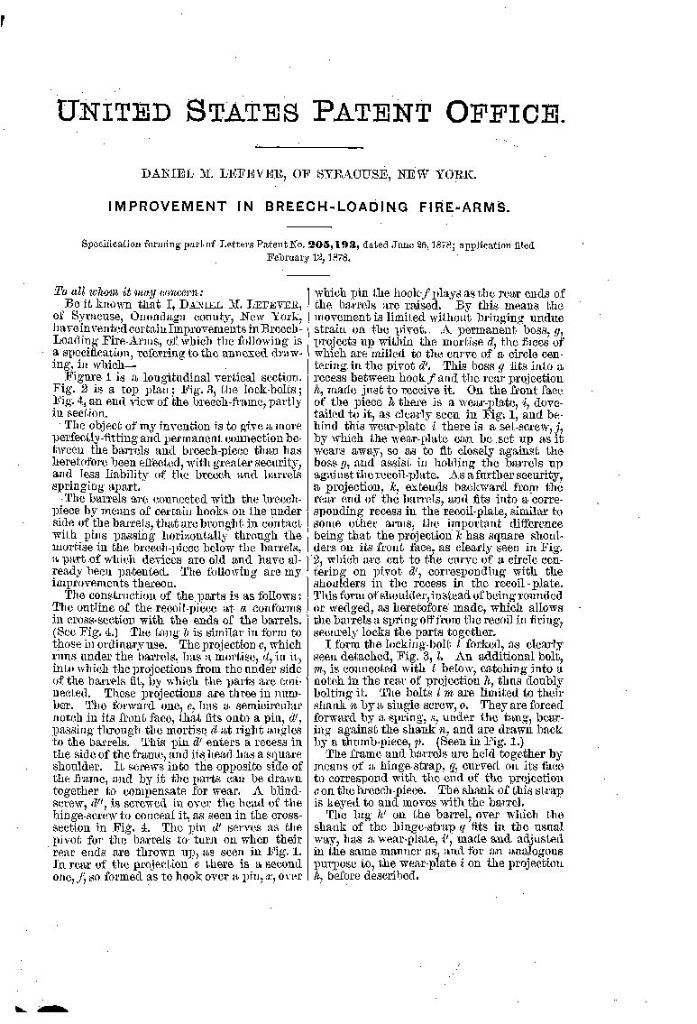

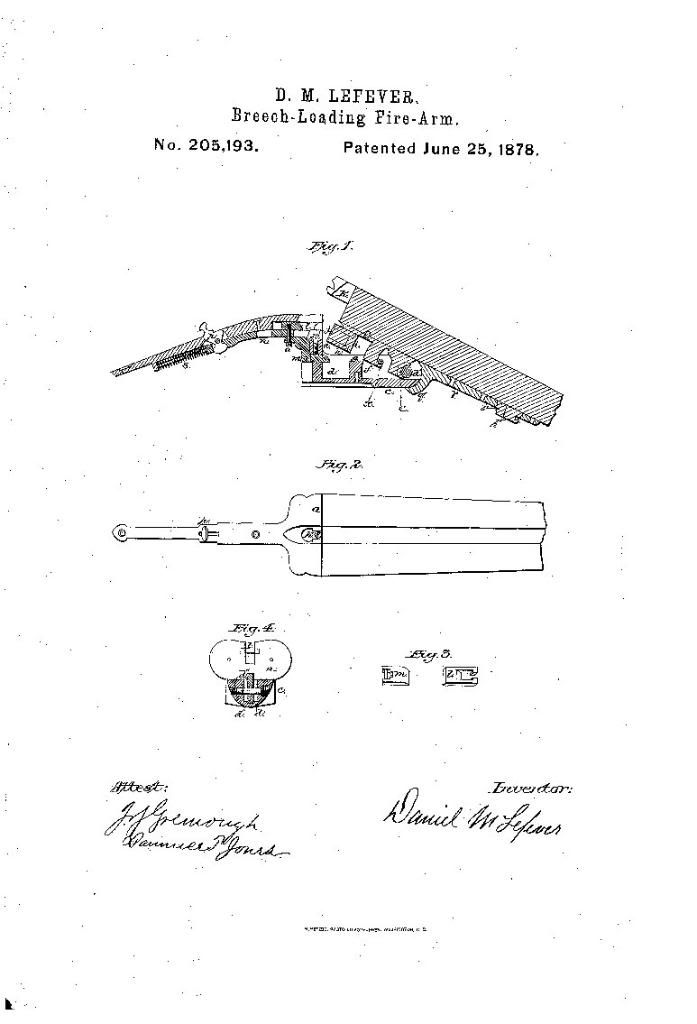

I do not believe it would have done so in the US. Note that D M Lefever was issued patent #205,193 on June 25, 1878 for a Doll's Head rib extension having a sq shoulder rather than the normal curved cone. Some time later Remington Arms began using a sq shouldered doll's Head on their doubles. Lefever sued for infringment & lost the case. The basis of his loss was that he had written the patent stating the mating surfaces of the Doll's Head & the recess in the breech were cut on the Arc of a Circle having the hinge as center. Remington won on the fact they had cut their shoulder on a straight line being tangent to the circle rather than a part of it. Lefever argued that the Sq Shoulders were the basis of the patent, not whether it was cut on a arc or straight, but Rem prevailed.

Jim;

Do you have any dates for the Pieper Demi-Block? This method is also often referred to as a dove-tailed Chopper Lump. It has often been stated this method began with BSA in England. From your info it would seem highly likely that Pieper preceded them with it. I had previously accepted that it was simply another name for the chopper lump, thanks for this additional info.

Wild Skies, can you describe the failure ? Was it a converted rifle ? Pretty early for a 410.

This gun was described to me as being built with "drop in lumps"--which are simply v-shaped, (as opposed to a dovetail lump that is v-shaped with a mechanical lock that holds the lump in place) the drop in lumps broke loose.

I have a copy of the ledger build sheet for this gun, #84XX that I obtained directly from Peter Powell in Birmingham, it was completed Dec. 24, 1886 and was built for H. Payne, the ledger sheet is hand written and states:

"1 Double barrel Collector Gun for a Lady, steel barrels 28 inches long, 70 bor cylinder taking .410 CF Cartridge. Toplever dbl. bolt with extension. Back-action rebounding locks with springs, Hackilt (? sp.) forend bolt, horn buttplate. Threaded engraving in deal. Care with cleaning rod. 200 bleu cartridges."

2-Piper, I have no information beyond what McIntosh said, and I can't seem to find my copy of "Best Guns" right now (1,000 years from now an archaeologist will excavate my filing system and mistake it for a rubbish heap). I seem to recall from discussions on this forum several years ago that Winchester probably got the idea from BSA, who probably got it from Pieper, but all claimed credit for it!

Pete;

Thanks for posting page two of the 1881 patent. As I have no reference to an earlier one I am taking this as his original patent. From both the illustrations & the description it is obvious this patent did not describe the bbls being threaded in. As to whether this patent was sufficient to protect against a gun being fitted with a one piece breechpiece with bbls joined by some other method in Belgium I do not know.

I do not believe it would have done so in the US.

Miller,

No problem. It is the earliest one I can find. If it is different from the Belgian version, I can not say. As I can not access the Belgian patents from that period online. Here is the information on the Belgian version -- BE53771 15.02.1181 Invention: genre d'assemblage de canons pour fusils double par Henri Pieper.

Yes, I am aware of the lack of threads. I usually go by that 1897 Sears ad. Assuming they changed the method over time. At least 16 years after filing the patent they had moved to threads.

I have a list of all his patents in French. If there a Pieper patent for a demibloc, I can not locate it on the list.

I have searched the US and European databases for any related patent(s) by Beretta, but have had no luck.

Here is a set of unfinished damascus tubes that I own. It is interesting to see the block at the breech which had to be formed by hand at the anvil. A good argument for going to a monobloc as a monobloc must have taken many hours of out of the process. To my knowledge all the early Pieper Diana guns used damascus tubes. Later versions finally made use of fluid steel. The Diana was marketed heavily here and in Germany. So many thousands of guns are involved.

Note that D M Lefever was issued patent #205,193 on June 25, 1878 for a Doll's Head rib extension having a sq shoulder rather than the normal curved cone. Some time later Remington Arms began using a sq shouldered doll's Head on their doubles. Lefever sued for infringment & lost the case. The basis of his loss was that he had written the patent stating the mating surfaces of the Doll's Head & the recess in the breech were cut on the Arc of a Circle having the hinge as center. Remington won on the fact they had cut their shoulder on a straight line being tangent to the circle rather than a part of it. Lefever argued that the Sq Shoulders were the basis of the patent, not whether it was cut on a arc or straight, but Rem prevailed.

Here is the Lefever patent

Pete

It would be interesting to see the ledger build sheet. Most unusual. So how did the gun fail ? Please advise.

I recall some of my guns having a thin braze joint line longitudinally, on the watertable, just outboard of the lump.

I was never certain of how the components were configured, but it sounds similar to the one Wild Skies described.

It would be interesting to see the ledger build sheet. Most unusual. So how did the gun fail ? Please advise.

I first noticed the lumps were loose when I removed the gun from it's period case and tried to assemble it. I had shot the gun quite frequently, mostly skeet and sporting clays targets for a period of 2-3 years after acquiring it from a fairly well-known SF auction house dealer at the Winter LV Antique Arms Show. Unfortunately I have no pics of this gun anymore, the fences were unique in the fact they were shaped like the torpedo cones that pop-singer Madonna is known to have worn on her chest.

Here's the ledger page that Peter Powell of Wm. Powell & Son had copied from their original ledger book and sent me. I cropped out a few other entries that are listed on the same ledger page.

This is from Ron Grabriels book "American & British 410 Shotguns".

Pete

It appears Mr. Gabriel missed at least one other .410---#8409, eh? Here's the complete ledger page from Wm. Powell & Son, the year 1886 is written in the top left corner:

In the U.S. both J. Stevens Arms & Tool Co. and N.R. Davis & Sons used the mono-bloc style barrel construction.

From J. Stevens Arms & Tool Co. General Catalogue No. 52, which some say equates to 1906 --

By J. Stevens Arms & Tool Co. General Catalogue No. 52 (Revised Edition) they had gone to the demi-bloc method. This from their 1912 Shotguns catalogue.

That last quote is interesting. Today, standard CIP proof is a good bit lower than SAAMI standards. Of course that catalog page predates the appearance of the Super-X and other "modern" shotshells, in the 1920's, which raised service pressures.