I have a few pix that I took to illustrate a talk I gave to friends in the Carolina Vintagers, no awards for photography but I think they might help.

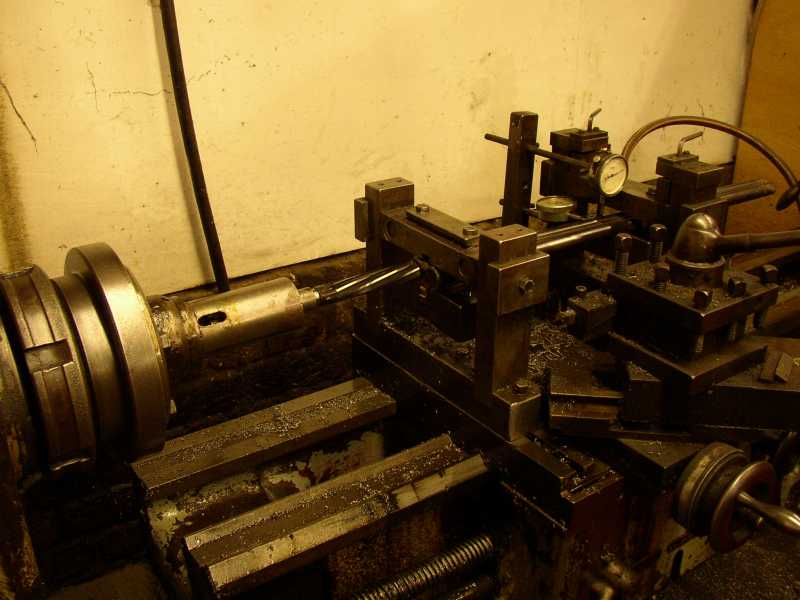

Here are the barrels being bored with a special boring tool. They are held in a jig to ensure that the new tubes are true to the original.

The monoblock has now been cut off to length and is ready to have its tubes inserted.

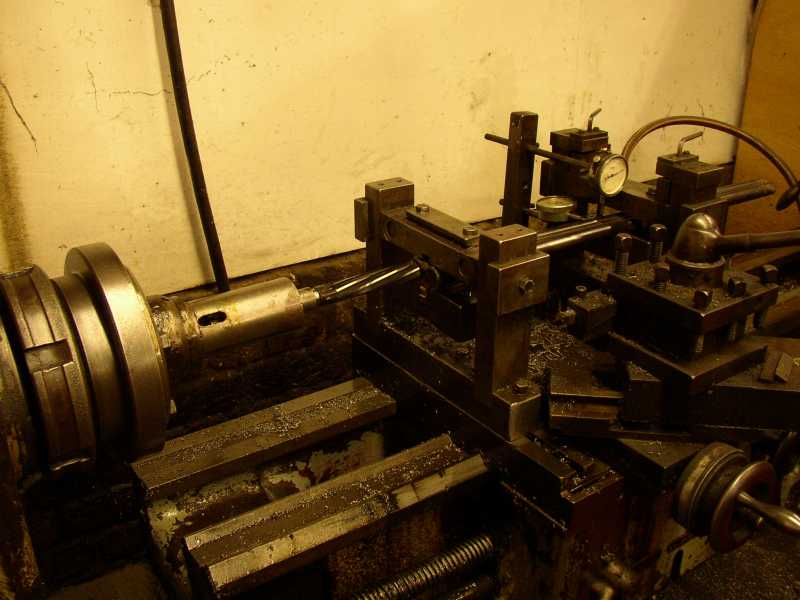

Another view.

Once the tubes have been inserted, they TIG welded at the breech face....

...and at the joint.

They are then tempered to avoid cracking, struck up, ribs relaid, chambered, extractors fitted, rim recess cut, choked, fine bored and lapped, polished, engraved and blacked.

Here are some fairly typical soft solder ones part way through the blacking process (sleeved by Westley Richards in the '70's).

Here are some TIG sleeved barrels that we had done at a similar stage of blacking. Note the band of welded material.

Interestingly, while soft solder joints often get more apparent with time, TIG welded joints tend to disappear over time.

Once the tubes have been inserted, they TIG welded at the breech face....

Once the tubes have been inserted, they TIG welded at the breech face....

[/img]

[/img]  [/img]

[/img]  [/img]

[/img]  [/img]

[/img]  [/img]

[/img]

[/img]

[/img]