I shot a Hatfield field grade heavily for about 10 years when I lived in South Texas and I put several thousand rounds of hunting loads through it. Fast and furious white wing and morning dove hunting, meant hot barrels on hot days. The shotgun never failed to function as it should. After about 5 years of heavy use my shotgun's tang chipped a small bit of wood out behind the top tang, I glued it back in and it went another 4 years or so, then I lost that bit and continued to shoot it some. Last year I gave that much used shotgun to my youngest daughter, so it is now on its second owner.

The hardware on this generation of Hatfield shotgun, as I understood it at the time, was made in Italy. I don't know who the "true manufacturer" was, but the final finishing and the wood was all done in St. Joe. Mo. (my home town). I think the wood was originally purchased to put on the Hatfield black powder rifles (where pressures were low) and was fairly highly graded maple and for some reason I think much of the wood may have been left over from the stock blanks that were used to make the black powder rifles (and simply too good to throw out).

The action on the field grade shotgun only improved with use (it was arguably too tight when new, but smoothed out to perfection and remains very tight to this day). But based on my experience, I do question the use of maple on a light 20ga.

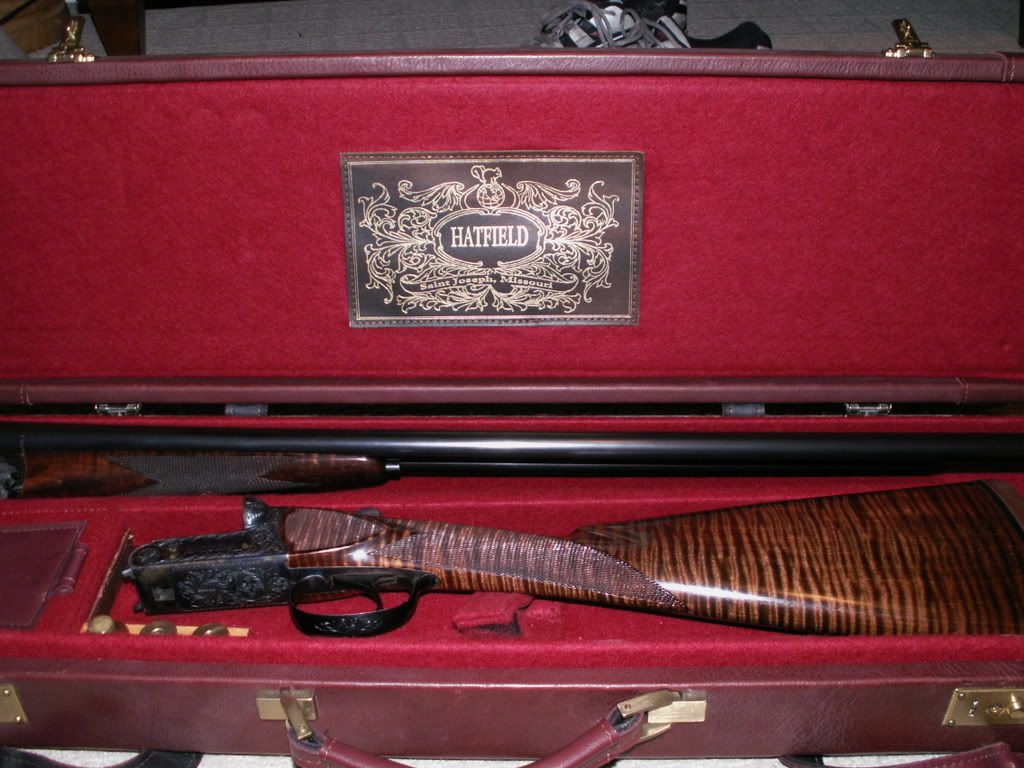

Below are photos of a gun that has been in our family since new (late 1980s') and I decided to put in my rotation last year. These older guns have nothing in common with the new Turkish made shotguns.