|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

|

|

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

|

|

|

|

|

|

|

|

|

Forums10

Topics39,561

Posts562,812

Members14,597

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Oct 2019

Posts: 7

Boxlock

|

OP

Boxlock

Joined: Oct 2019

Posts: 7 |

Hi, new member here and recently caught the double gun bug. I recently purchased a circa 1880s Charles Osborne back action hammer gun. It was very loose and had minor pitting on the twist steel barrels. All the finish was rubbed off but I could see the original Browning under the forend. I am very interested in working on these Birmingham guns so this was a perfect learning gun because it is plain, inexpensive and in good condition just well used and worn out. I started by disassembling the locks and cleaning out the gunk. I had my dad machine me a slightly oversized hinge pin and ream out the action hole ever so slightly. I then fitted this pin, blackened the hook and barrel face over and over again and filed bit by bit until the gun was nicely rejoined and closed tight. I filed the sears until I got the trigger pull just how I wanted it.I still need to file the pin flush with the action. The stock I cleaned with mineral spirits then applied raw linseed oil followed by boiled linseed oil. I have now bead blasted the barrel set and fine steel wooled it. I plan on rebrowning and acid etching them but here's the thing. After bead blasting I have discovered a couple pin holes in the solder in the gutter of the upper rib. I turn the barrels up and down and you can hear the rust under there. The barrels ring nicely nevertheless. I am thinking of relaying the ribs because I am worried I get a nice finish and then the rib pops when I start hunting.I realize it is a big job and not straight forward. I would practice on scrap barrel set first. Anyway great to be part of the forum, I have already spent hours browsing all the knowledge on here. -Ken

Last edited by KennyT; 10/23/19 06:34 PM.

|

|

|

|

|

Joined: Mar 2002

Posts: 7,893 Likes: 651

Sidelock

|

Sidelock

Joined: Mar 2002

Posts: 7,893 Likes: 651 |

Leave the ribs as they are if they ring. Lasted 140 years so far. I would buy a couple sets of odd barrels to practice and learn on. EBay is a good place to find them. That bit of rust might just be a bit of solder that has been there for a century. As to the soldier missing it most likely is just an area on part of the ribs. But if you want to lay ribs use the practice set first. If you screw them up itís no big deal.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,777 Likes: 467

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,777 Likes: 467 |

Well done Kenny. There is a damascus refinish tutorial here https://docs.google.com/document/d/18MIvJwHhLh87zYiUDOQ4RkZKw7b42sUhVKz_9HMDdv4/editCould you please share the barrel wall thickness numbers at the end of the chamber, just past the chamber, at 9" and 18", and the minimum wall thickness and where? Does the gun carry Nitro proof?

|

|

|

|

|

Joined: Oct 2019

Posts: 7

Boxlock

|

OP

Boxlock

Joined: Oct 2019

Posts: 7 |

At 9" the bores are .717 diameter and the barrel flats are marked a 13. I fired three 2 1/2" shells through each barrel remotely and then inspected them carefully after bead blasting and I see no faults in the barrels. The gun only has black powder proofs, it has been in Canada for much of the last part of it's life we have no proof houses here. I would be interested to know how to measure the thicknesses you spoke about, I understand how to measure bore diameter and have the means to do so. I have only measured it at 9".

Last edited by KennyT; 10/23/19 07:01 PM.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

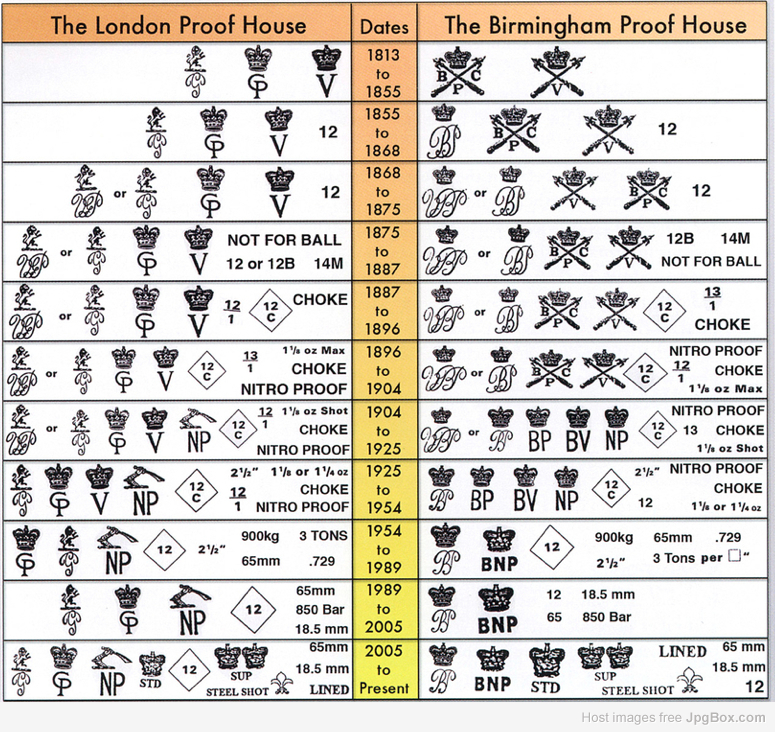

Note that Kenny said the gun was from the 1880s. If it was proofed prior to 1887 then the 13 marks could indicate a bore diameter from 0.710" up to just under 0.729". The 13/1 size (.719") was not used prior to 1887. In this case, it would be immaterial as the current size is between 13 & 13/1 anyway, in proof either way it goes.

By the proof marks, you can tell whether it was proofed under 1887 rules or earlier ones.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Oct 2019

Posts: 7

Boxlock

|

OP

Boxlock

Joined: Oct 2019

Posts: 7 |

Thanks Drew, great articles I will have the bores scoped and do some more measuring before I deem the gun safe/unsafe to use. Charles Osborne records have been lost unfortunately so the serial number does not allow one to date it using that. It is a basic gun but it has the Purdey bolt with Scott Lever so The 14 year patent would have expired and the name on the rib does not have LTD on the end of the name which happened in the 1890s, that is how I narrowed down the date

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Kenny'

If the proofs show a chamber mark as in 12/C in a diamond then it was proofed after Dec 1887. If it does not have the chamber mark it would have been proofed prior to Dec 1887.

In either case, it would have the 13 denoting bore range at the time of proof. but after Dec 1887 the chamber size was designated.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Oct 2019

Posts: 7

Boxlock

|

OP

Boxlock

Joined: Oct 2019

Posts: 7 |

Very interesting 2 Piper, it does have the 12C in a diamond so that narrows the date of manufacture to between January 1888 and 1896 when the company became Limited.

|

|

|

|

|

Joined: Feb 2016

Posts: 3,554 Likes: 469

Sidelock

|

Sidelock

Joined: Feb 2016

Posts: 3,554 Likes: 469 |

If it will help, I'll post the London-Birmingham Proof Mark chart from Diggory's book again. It will have "Not For Ball" 1875-1887.

Baluch are not Brahui, Brahui are Baluch

|

|

|

|

|