|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

Forums10

Topics39,819

Posts566,035

Members14,620

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

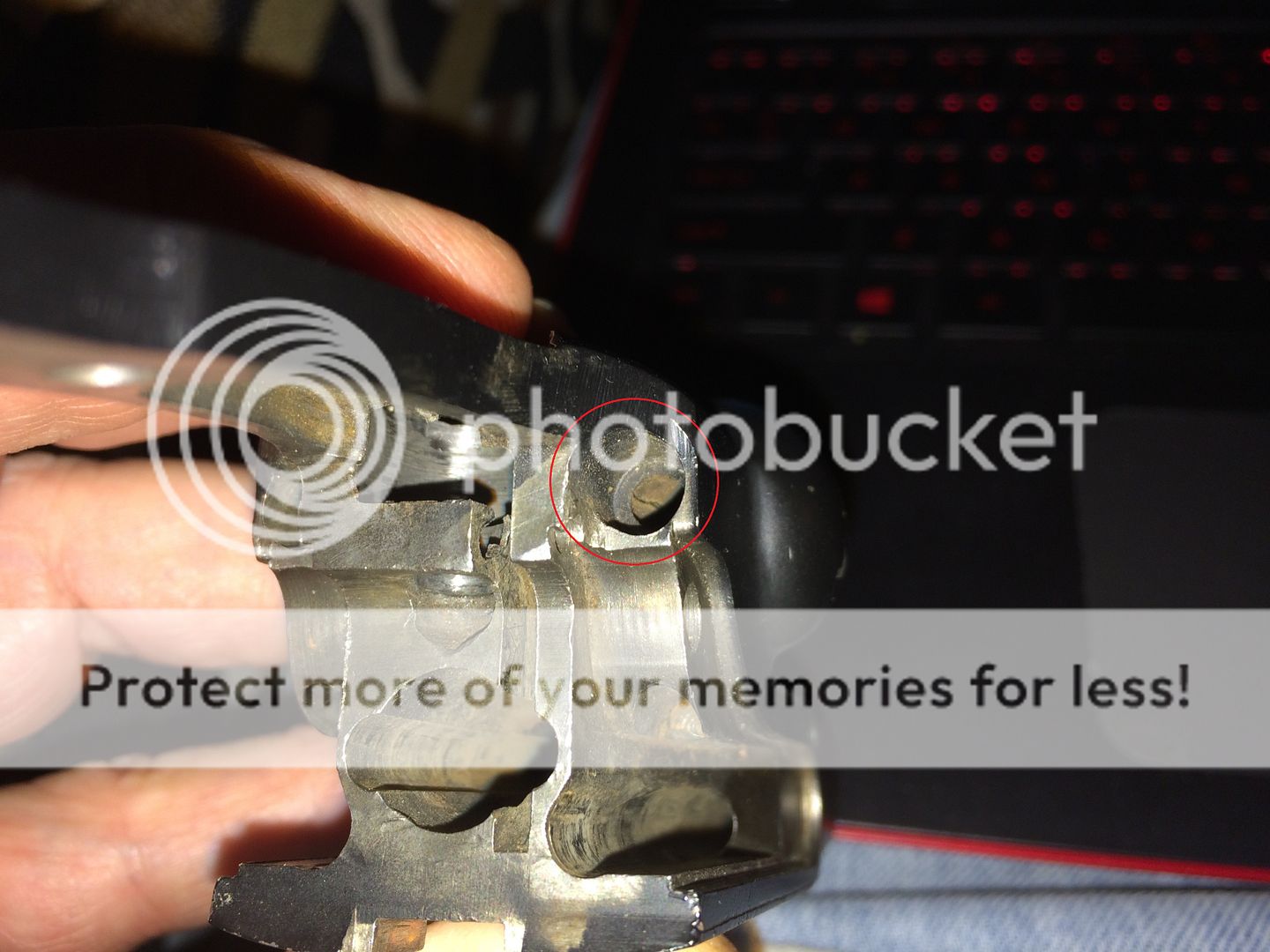

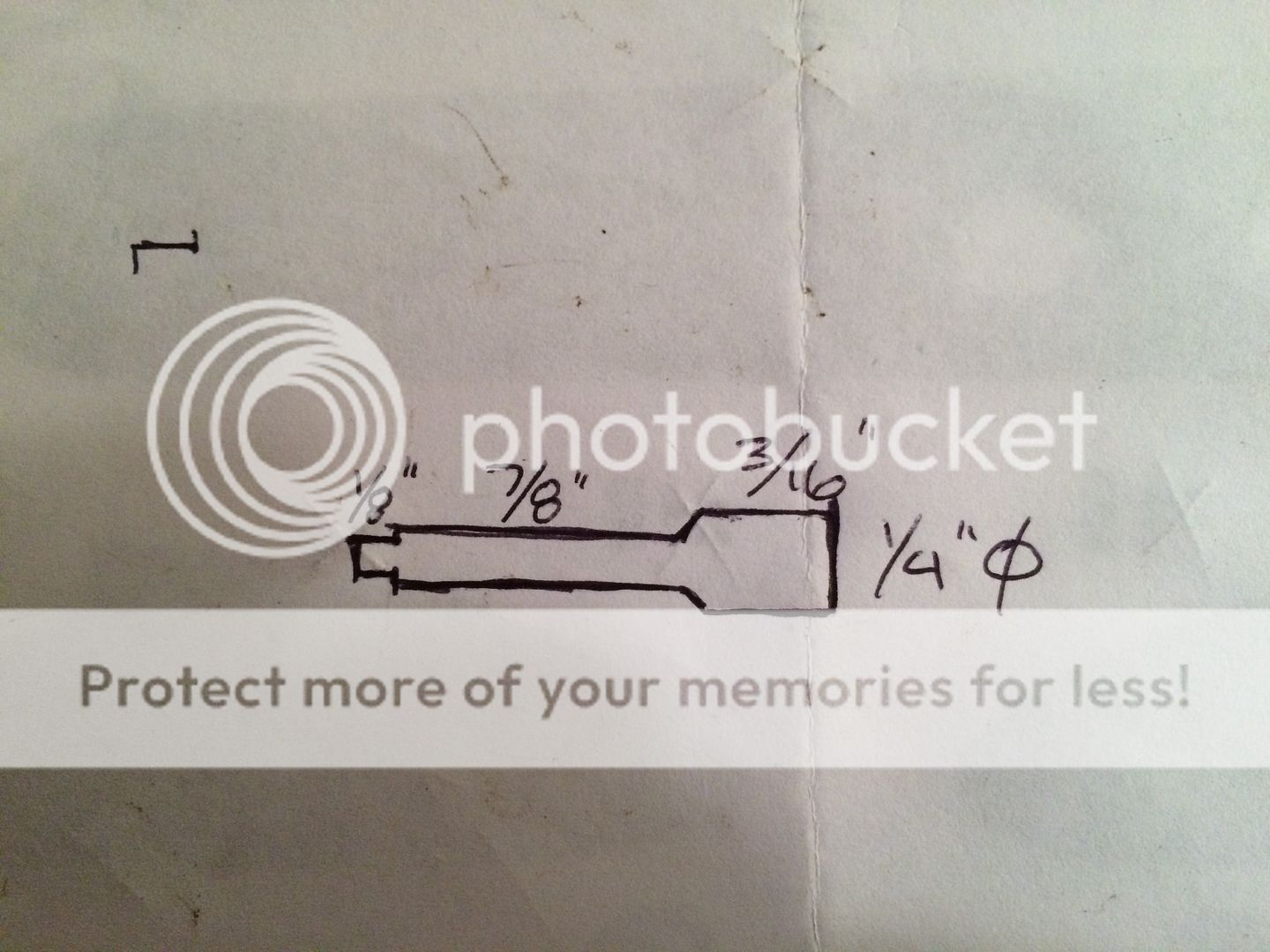

Hello all. Still playing around with my 20ga Meriden SxS. I'm going to try and have some firing pins made and a suggestion in a older post said to use Cerrosafe. Watched many videos on Youtube but they have all dealt with casting a barrel and the casting was pushed out with a rod. Here's a pic of my receiver showing the firing pin location and a drawing of what the firing pin location looks like (to the best of my knowledge) My question has to do with anyone having an idea of how to get the casting out given that I can't force it out with a rod? One thought I had was to insert a drywall screw into the casting before it has a chance to harden. Any other/better thoughts? Thanks Kirk

|

|

|

|

|

Joined: Feb 2002

Posts: 1,926 Likes: 230

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,926 Likes: 230 |

Why can't it be pushed out from the breech face w/a small dia rod through the firing pin hole?

Unless I'm missing something, the firing pin hole in the breech face will have to be plugged anyway to keep the cerrosafe from draining right through as you pour it in the back end of the cavity.

Just put a piece of masking tape or DucTape over the firing pin hole on the breech, or clamp a smooth piece of wood up against the hole to block it.

Pour the casting, let it harden a few minutes and push it out from the face of the breech.

Don't let it set in the action till it gets room temp. The stuff will have expanded back to full size and have locked itself in place then and you'll have to heat it up and melt it out and start over.

While it's still warm/hot but solidified,,the material is something like 5% smaller than the actual cavity it is casting.

It returns to full size when cooled. That reduction in size allows removal w/o damage to the casting.

Warm up the frame a little too before you pour in the cerrosafe. The casting will be smoother and more complete w/o wrinkles,,just like bullet casting but you're only dealing with 212F material instead of 700F lead.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Kutter, thanks for the reply. What you say makes sense. In some of the videos I watched they really had to pound on the casting to get it out. I was concerned that pounding thru the firing pin hole would deform the casting. Obviously the initial reduction in diameter along with some lubrication will help.

We'll see how it goes.

Kirk

|

|

|

|

|

Joined: Jun 2008

Posts: 5,696 Likes: 226

Sidelock

|

Sidelock

Joined: Jun 2008

Posts: 5,696 Likes: 226 |

What model is your shotgun?

Last edited by skeettx; 10/03/16 12:54 PM.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Morning skeettx, appreciate the reply. My gun is a 20ga SxS with the model unknown (no markings on gun). It is a plain Jane entry level gun that needs some work. From what I can tell the model 235 is a pump gun. The schematic on their site is for a 12ga and the firing pins are different in that they are retained. From what I believe, the firing pins on this gun are retained by the sideplate and possibly the stock??? Drew and PeteM have replied to some of my posts and there isn't much out there on 20ga models and not many found. Still doesn't make it worth much and I'm just puttering around with it to see if I can get it shootable. Several of the parts will have to be reverse engineered and the stock is toast. We'll see where it goes. Previous posts on this gun can be found at http://www.doublegunshop.com/forums/ubbthreads.php?ubb=userposts&id=18405 and pictures of the gun found at http://www.doublegunshop.com/forums/ubbt...8664#Post428664Thanks Kirk

|

|

|

|

|

Joined: Jun 2008

Posts: 5,696 Likes: 226

Sidelock

|

Sidelock

Joined: Jun 2008

Posts: 5,696 Likes: 226 |

USAF RET 1971-95 ![[Linked Image from jpgbox.com]](http://www.jpgbox.com/jpg/57865_80x60.jpg)

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

No problem skeettx, I can relate. I'm pretty certain that the parts shown are for a 12ga gun. The firing pins shown require the use of a seat which threads into the receiver which is consistent with 12ga guns I've seen pictures of. In fact I have those parts from a purchase I made off eBay. My receiver isn't threaded to take the seat. Been awhile but pretty sure the pins don't even fit in my receiver.

Kirk

|

|

|

|

|

Joined: Feb 2009

Posts: 7,729 Likes: 356

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,729 Likes: 356 |

Unless a gunsmith is going to fit the firing pins for you, I think at best you'll just be in the ball park. I think you could get a couple of turnings based on your drawing, verify it, maybe request things a bit long for final fitting. I'm probably seeing it wrong, but before going on, maybe figure out how the firing pin is going to be retained, and if any of that room in there is for a spring. I'd kind of figure on knowing which way the firing pins or gasses are headed if you pierce a primer. Best of luck with it.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

All good points craig. Quite honestly I'm hoping that the collective wisdom on this forum will be of great help (not that they haven't been up to this point). Even those on the forum with the most Meriden experience are unsure what the guts should look like. At some point I'll enlist the services of a gun smith, particularly to remove some dents from the barrels. Maybe also for the firing pins. Apparently, there aren't too many 20ga Meridens around (if any) so no one is able to tell me this is how it should be. Not sure a gun smith will be able to help more than those on the forum but you never know.

The receiver isn't threaded for firing pin seats so retaining the firing pins must be done by the stock and/or the side plate. It is my understanding that while not common it isn't unheard of. In looking at my receiver and stock, I can see how it is possible. As for a spring, I again understand that it is not uncommon for these old guns to not have one although it would be nice. Might be possible to figure this out as long as it will work with the retaining method that I end up using.

Agreed that it will be a trial and error process. I think that I can get close. First step will be to make the casting and see where it goes from there.

If you have any insight or wisdom you can send my way I sure would appreciate it. My guess is that you have a lot more experience than I have. For instance, your comment about piercing a primer intrigues me. I haven't heard of that but my guess is that it has to do with the FP projecting far enough to pierce thru the primer. Doesn't sound like fun. I seem to remember a rule of thumb relating to projection of the FP related to it's diameter (or something along those lines). Again, any advice is appreciate.

Kirk

|

|

|

|

|

Joined: Feb 2002

Posts: 1,926 Likes: 230

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,926 Likes: 230 |

re:cerrosafe...absolutely get the casting out of the cavity as soon as it solidifys. It'll push right out.

Wait till it's cold to the touch and it'll be locked in place.

Do wait to measure it w/calipers or mic til it gets to room temp if you want a true reading. Otherwise you'll be getting that % shrinkage that allowed the easy removal while still hot.

Firing Pins,,,

Make the firing pin a nice rounded front tip. The total protrusion should be about .045" Thats more than enough to fire any cartridge and still not punch deep enough to pierce the primer.

I doubt springs were used to retract the firing pins. Most SxS's from the early to mid 20th cent that had separate firing pins from the hammers didn't have spring loaded pins.

The LC Smith side lock would be the closest to your Meriden in comparison and those were held in place by the stock wood and/or the lock. Taking the locks out of the stock and tipping the stock upwards on most LCS's will drop the firing pins out onto the floor for you.

Box lock Ithacas like the NID and the Nitro Specials have separate pins & use no springs to retract them. The Ithacas do use a set screw to limit travel of the pins in the frame but not for forward travel/protrusion. But rather rearward motion so they don't fall back and out of their seat from where they are installed.

Of the Meriden SxS's & singles I've owned (all 12ga) none had spring loaded pins.

These all depend on proper length of the pin (protrusion) and the small cut-out channel in each extractor to guide the pin back and out of the way as the bbl is closed so they don't jam the action.

A properly timed action with regard to the cocking arms/linkage will retract the hammer as the bbls are opened. That takes the pressure off the firing pin on a fired hull so there is no drag of the pin on the fired hull primmer. Removes any 'over the knee' opening antics.

|

|

|

|

|