Actually, lately I've been using a modified form of the Original Parker Process. The one that Dr. Gaddy described in DGJ back in 2003. Are you familiar with it? I've gone to the five-minute battery acid soak initially, then application of the two solutions for each cycle. I'm going to be working up a thread on it eventually.

Where did you find Spirits of Nitre? For brown and white I'm using C.19. It gives a nice color. For all barrels I now scald after rustings, rather than boiling. A 10 minute soak in hot tap water with a water change at the half-way point enables a partial conversion of the rust. It was too hard for my wheel to remove it easily without it. I also use C.10.C quite a bit, for black and white, it gives a nice deep color.

I've found that the first of the two Parker solutions (CuSO4 & HCL) works as an etch, causing pattern to develop earlier. It just has to be applied with a well squeezed sponge. It also usually eliminates the need for intermediate etches, as the logwood boils at the end (up to three) contain Copper Sulphate as well, providing more etching action. One thing I've gone to that I really like is using Calcium Carbonate to scrub the barrels with after each etch or logwood boil. Rather than buy Whiting I'd have to order, I use powdered Lightweight Drywall Compound which I mix up as a paste to rub on the barrels. I think it's much better than baking soda, a little less abrasive so there's less chance of disturbing the pattern. Hope I answered your question.

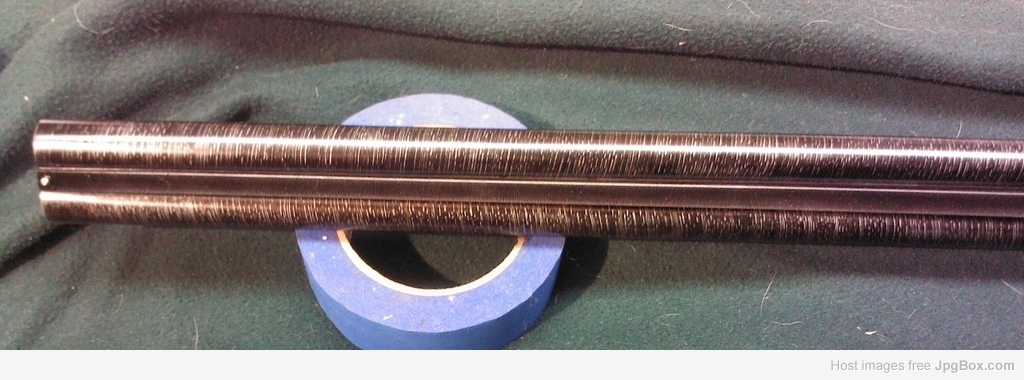

Here's a set of Syracuse New Twist tubes I used the process on.

Regards

Ken