|

S |

M |

T |

W |

T |

F |

S |

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

8

|

9

|

10

|

11

|

12

|

13

|

14

|

|

15

|

16

|

17

|

18

|

19

|

20

|

21

|

|

22

|

23

|

24

|

25

|

26

|

27

|

28

|

|

|

Forums10

Topics39,925

Posts567,787

Members14,633

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Nov 2014

Posts: 367 Likes: 18

Sidelock

|

OP

Sidelock

Joined: Nov 2014

Posts: 367 Likes: 18 |

Gents,

I have read where this is done. My question is, does the neck have to be reamed/turned? I built one dummy round for my Sauer & Sohn Tell V using Norma 9.3x72R brass. Once it is shortened, it fits at all stages of forming up until the time a bullet is seated. The bullet is a RWS 12.5g jacketed number. I have misplaced my chamber cast and will likely try another today. Just curious if this is to be expected.

Thanks!

Hoot

|

|

|

|

|

Joined: Jul 2012

Posts: 5,004 Likes: 386

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 5,004 Likes: 386 |

Hoot,

The necks may have to be turned/reamed, depending on the rifle's chamber.I have an aversion to shortening 9.3x72R cases for this and other cartridges.This is a "generational"thing I think, because I'm old enough to remember having to struggle to find even berdan primed 9.3x72R cases. Cases are easier to find now, but I still prefer using 38-55 cases in the original length, rather than the current 30-30 length cases.Even though about 1/8" short, I would use 38-55 case and just seat the bullet "out"and center the case in the chamber( also for 8x57r/360, 8x58R S&S,and 9x58 1/2R S&S).Starline makes the longer cases, for those that don't have old ones.

Mike

|

|

|

|

|

Joined: Jun 2008

Posts: 5,696 Likes: 226

Sidelock

|

Sidelock

Joined: Jun 2008

Posts: 5,696 Likes: 226 |

For neck reaming, contact Forster and they may have a .366 inside neck reamer. http://www.forsterproducts.com/store.asp?pid=26888Mike

Last edited by skeettx; 06/03/15 09:04 PM.

USAF RET 1971-95 ![[Linked Image from jpgbox.com]](http://www.jpgbox.com/jpg/57865_80x60.jpg)

|

|

|

|

|

Joined: Mar 2012

Posts: 235 Likes: 6

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 235 Likes: 6 |

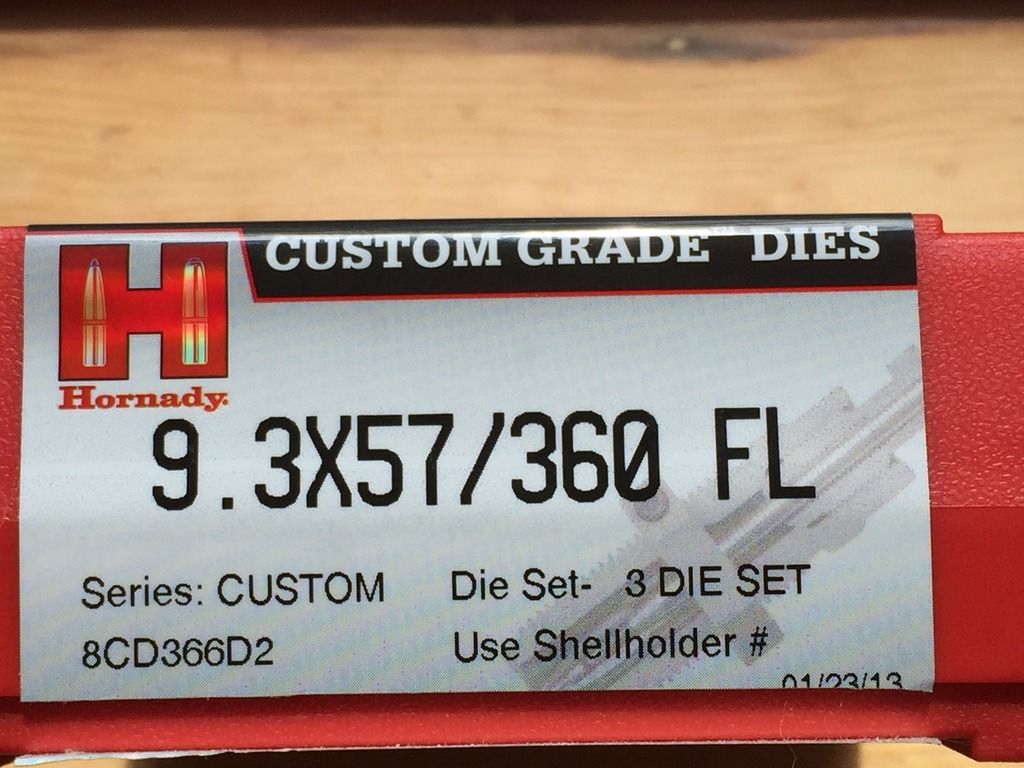

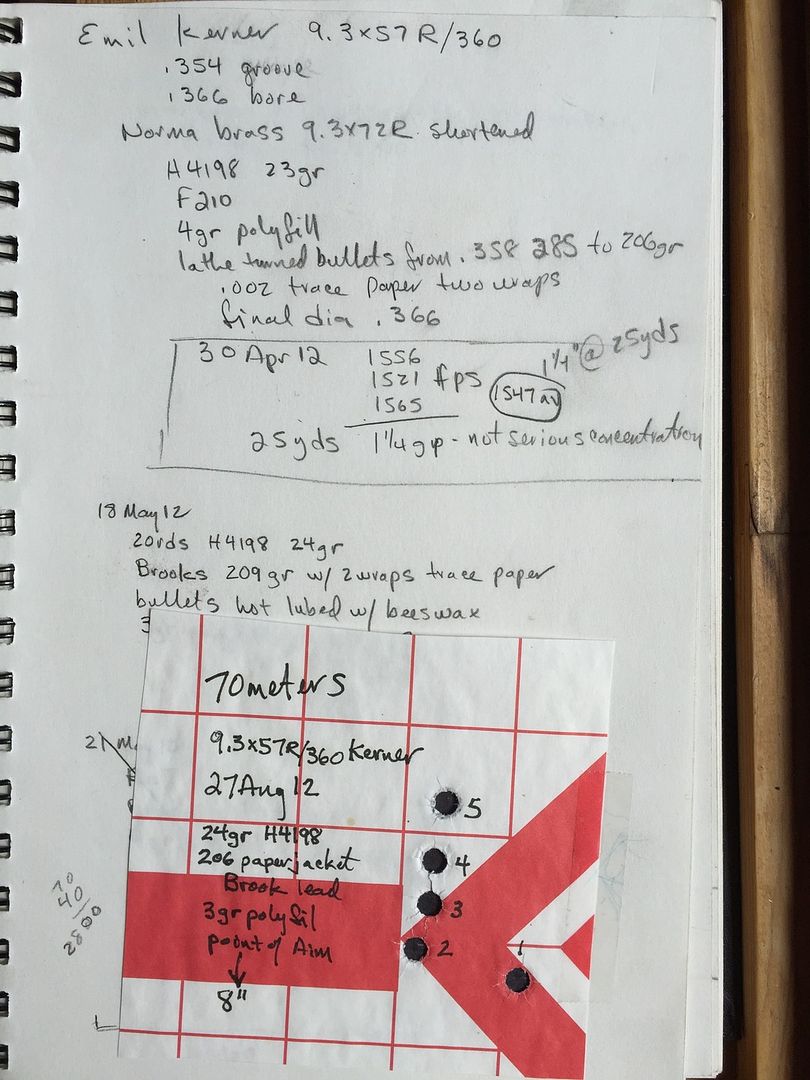

Hoot, Here is how I solved the problem. Hope it isn't more than anyone wanted to know. I started by slugging the bore and doing a chamber cast of my Emil Kerner rifle. This confirmed that I had the right cartridge.  I found a set of beat up 9.3x72R dies on eBay and shortened the FL die so that I could size cases sufficiently to chamber them. From some old 9.3x72R cases I made three test cases that I outside neck turned to get a proper neck thickness. Finally, I reduced the length of three .358 cast bullets so that they weighed 206 grains, paper patched them up to .366 and fired them. These three cases were sent to Hornady and a three die set was made.  The outside neck turning resulted in mediocre cases and when the dies arrived I could make good ones. The outside neck turned cases are used for shooting light round ball loads.  New RWS 9.3x72R cases were marked with a felt tip at about 60mm and using a disk sander I aggressively shortened the cases to this mark. The necks turned a dull red for a short distance from the cut end and slight heating could be felt at the head. The cases were allowed to air cool and then were trimmed to 57mm on a case turner. The heating resulting in sufficient annealing and length trimming was not difficult. I determined that my inside neck diameter needed to be .362 and ordered an inside neck reamer from Forster. Because the long original case was shortened so much wall thickness was significant in the shorter version. The neck reamer leaves a shoulder inside the case but it is slightly below the seating depth of my bullet.    Steve Brooks made an ungrooved bullet mould for me that casts 209 grain bullets that patch up to .366.  Some final cartridges and the results.   I have some work to do with the vertical stringing and Petrov suggested that my forearm positioning on the rest was inconsistent. Dennis

|

|

|

|

|

Joined: Jul 2010

Posts: 667 Likes: 58

Sidelock

|

Sidelock

Joined: Jul 2010

Posts: 667 Likes: 58 |

Good work and great write-up Dennis!! I'm inclined to agree with Mr. Petrov. With that load and the filler I wouldn't think ignition a problem.

NRA Benefactor 2008

NRA Patron 2007

NRA Endowment 1996

NRA Life 1988

|

|

|

|

|

Joined: Nov 2014

Posts: 367 Likes: 18

Sidelock

|

OP

Sidelock

Joined: Nov 2014

Posts: 367 Likes: 18 |

First off, thank you one and all.

Secondly, Dennis, my goodness, exactly the information I needed! Thank you!! No worries about more than I asked.

Things got a bit out of hand the last couple of days so I am no further along but it'll come back around in the next day or so. I suspect paper patching is in my future. For now, I have a small supply of jacketed and some pre-cast .366's. I can also see a mold in my future.

BTW, mine is not Nitro proofed so I will be filling the case with black. What are the implications of black with jacketed? Worth the effort or just skip it?

|

|

|

|

|

Joined: Mar 2012

Posts: 235 Likes: 6

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 235 Likes: 6 |

Sorry, Hoot, I have no experience with black powder. With a 1700 fps velocity I felt I would get better performance (20:1 alloy) for hunting than a metal jacketed bullet. Paper jacketing is more effort but has advantages for me.

The new brass I was working with is Norma not RWS as stated earlier. It was a cost issue and for this type of use I don't think it matters between the two brands.

I don't believe my rifle is nitro proofed either. Ross Seyfried's article on three of this class of cartridges is most useful information. Handloader #225 Black Powder Express Cartridges.

Dennis

Dennis

|

|

|

|

|

Joined: Jul 2010

Posts: 667 Likes: 58

Sidelock

|

Sidelock

Joined: Jul 2010

Posts: 667 Likes: 58 |

Implications of black with jacketed are one, no lube to soften the fouling. I've never shot jacketed bullets over black but don't believe I would expect much for accuracy. Sort of a second issue is the harder jacket material of jacketed bullets working on the softer iron/steel barrels of the BP era. Hawk bullets annealed dead soft at about 25 BHN are an exception...albeit a rather pricey exception for plinking. Personally I'd just skip them. Black and cast go together like peaches & cream.

NRA Benefactor 2008

NRA Patron 2007

NRA Endowment 1996

NRA Life 1988

|

|

|

|

|

Joined: Dec 2001

Posts: 7,461 Likes: 770

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,461 Likes: 770 |

I shoot the magnum version,  2&7/16" in length and can cram an extra 5 grains of black into my cases for a 60grain compressed load of Swiss with a hard card wad and for plinking I use Hawk bullets. The accuracy is not too bad. I pulled the flyer. Target at 50 yards.

Last edited by SKB; 06/04/15 04:24 PM.

|

|

|

|

|

Joined: Jul 2012

Posts: 5,004 Likes: 386

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 5,004 Likes: 386 |

Hoot,

You didn't post photos of your rifle, including proofmarks. This might show bore(not groove or bullet) dia.and case length.Sauer and Sohn chambered for a cartridge very similar to 9.3x57R/360. This cartridge is 9x58 1/2R S&S and is very often confused with the 9.3x57R.I couldn't find where you slugged the barrel.If you haven't done so, you should. Old 9.3s are found with groove diameters of from .352" to .368" (the jacketed bullet you used is the standard 9.3x72R bullet and is made to be safe in any of them).If the barrel has an uneven number of grooves,you may have a little trouble measuring the slug,because the grooves in the barrel are not opposite each other.For cast bullets, I prefer a bullet about .002" over groove diameter.BTW, when I use the term groove diameter, I mean the larger diameter, and for bore diameter, I mean the diameter before the grooves are cut. I only mention this because SKB shows it the other way, and I don't want to confuse matters.I have no experience with paper patching bullets, so will leave their diameter to SKB and Sharps 4590. If your rifle is not nitro proofed, you can load nitro for black with good results, although some black powder rifles may be more accurate with black powder and proper bullets and lube.

Mike

|

|

|

|

|