|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

1 members (welder),

461

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,824

Posts566,187

Members14,622

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

I guess I needed to be a little clearer. I'll use the kiln for the lead tempering bath, not for the nitre. I'm planning on using the side pot burner on my propane grill for the nitre. I'll use a cast iron pot in both processes.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,162 Likes: 256

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,162 Likes: 256 |

Hi all

This seems to be a multiple subject thread so I hope you don’t mind me adding what I feel is a little clarity to things.

Firstly Jack Rowe’s method of tempering a spring (actually drawing the temper we say here) that is after heating to cherry red and quenching the next thing you do is draw the temper by re heating again. If you listen to him he is using the old flare method using ‘Whale oil’ a very common method here for making small springs up to the 1950s but now not possible and rightly so. Is there an alternative yes! Lard works well it burns at about the same temperature as ‘Sperm whale Oil.’ Next is what is cherry red? Now as simple as it may sound it is hard to get right especially if you are heating up the metal under any form of electric light because it changes the colour considerably. I was once lucky enough to visit the Black Smith and Farrier School here in Salisbury and the forge rooms had extremely low level of lighting to the point of darkness so the tempering colours could be seen more clearly. When flame treating steel subdued lighting is a must. Now for a very old tip I use for tempering springs using an open flame after you have heated the steel to cherry red. If you use an open flame to draw the temper to the correct colour the thin parts of the steel heat up faster than other parts and you end up with more colours on the steel than “Josephs Coat” and the spring will more than likely break. The method I use is to heat the part in ‘Silver Sand’ in a metal tray in doing it this way the sand absorbs the heat very slowly and evenly, so you burry your part just below the surface it will heat up slow even and you can move some of the sand covering the part now and again to see how things are progressing, when the correct colour is attained quench it in water or oil doing it this way its temper will be even,

Nitre Bluing the components for this is many and varied. Now during WW2 in many countries but not the USA as far as I know, UK, Germany, USSR, used NPK Fertilizer because pure Potassium or Sodium Nitrate was hard to get but lots of fertilizer stocks at the start of the War, and these mixtures gave differing blue colours. I would like to say here that heat liquidised Potassium Nitrate is an extremely powerful oxidiser if it spills on any combustible material that includes YOU!! It bursts into flames instantly, and you for the ‘Hospital Burns Unit.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

In the 1950's an Arizona USA Gunsmith named Roy Dunlap published a book "Gunsmithing". In this book he mentioned using Ammonium Nitrate fertilizer as a component in a home brew Hot Salts bluing formula. I tried some of it & it did produce a good blue but had an excessive amount of Sludge in the tank, am thinking the inert filler mat'l had been changed from when he had used it.

I believe the term "Temper" is correctly used alone. To temper the heat treated steel you Draw the Hardness, you do not draw the temper.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Jan 2013

Posts: 1,162 Likes: 256

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,162 Likes: 256 |

They do say “Separated by a common language” 2-Piper try Google “Drawing the Temper” you will find what I said is correct and just as a reminder, over here we have been bashing metal a lot longer so for better or worse we Brits where first to use the wording to describe the process in English.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Thanks damascus,

You're really "in for it now"..

Now, a little clarification is needed. (at least for me) Please pretend that you're dealing with a thirteen-year-old that has only a basic understanding of the processes involved.

Ok, after you've brought the spring to cherry red and quenched it, you bury it in Silver Sand in order to draw the temper.

How are you heating the spring and sand? Torch, oven, or burner?

Is it coated with lard at this point?

How do you tell when the spring is at the correct temp?

Silver Sand appears to be mainly crushed quartz. I have bags of crushed quartz I use in my horticultural experiments, (part of a soilless potting mix) will this work?

Lastly, the inevitable question: Have any pictures?

Regards

Ken

Last edited by Ken61; 05/16/15 07:24 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,162 Likes: 256

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,162 Likes: 256 |

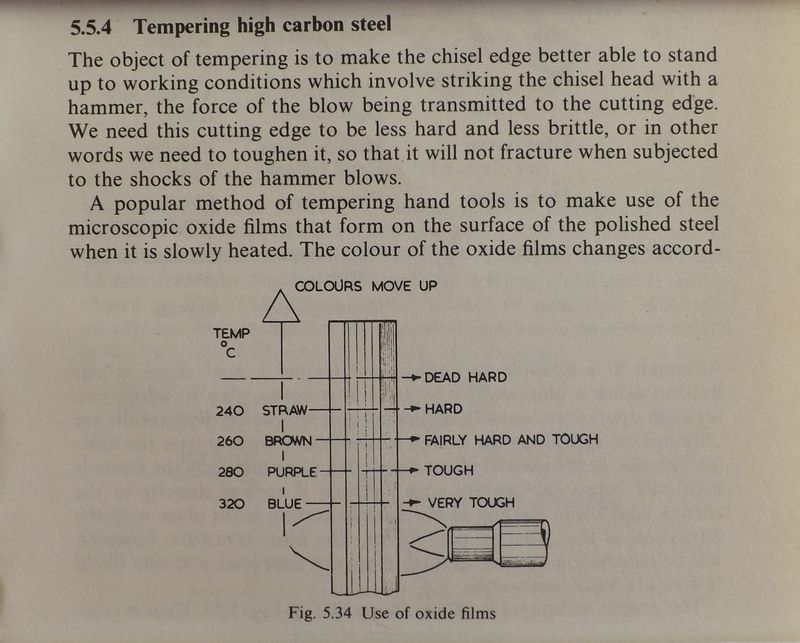

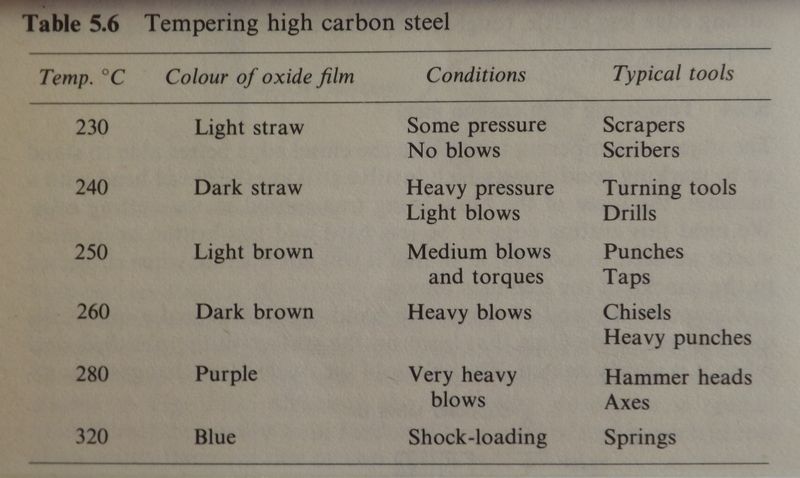

Just to make it easier for me I will use the Brit wording to describe how to harden ‘high carbon’ steel to the correct state for use. So just this once please and for this exercise only can we meet half way across the pond with the language? We bloody Brits use the term “hardening and tempering” to describe the simple heat treatment of high carbon steel. The first part of the statement hardening!!!!! This means that the steel is brought to cherry red in colour in subdued lighting and kept there “soaking” depending on the steel for thirty seconds to about two minutes. Subdued lighting is necessary so you can see the steel colour correctly because if you overheat the metal you can what we say “burn it” this just means that by overheating the metal you can change its characteristics permanently. After being kept at red heat for the correct time period it is then immersed into either water or oil this can depend on the steel used but what you call “drill rod” and we call “silver steel” you can use either. Now this rapid cooling hardens the steel to what we say is “dead hard” condition, and in this state it is next to useless in fact if you were to give it a heavy blow it would shatter like glass. Now comes the tempering (Explanation we Brits say “drawing the temper” which translated to modern speak is “moving the temper” from dead hard to a more useful level of hardness. Ken things are getting a little busy here I have to do a sort of tutorial on how to do a Vintage London stock oil finish that is on the Baikal I have just finished I do sometimes think I should keep quiet!! WITH ME SO FAR??? GOOD!! Now To draw the temper we use the surface oxide colours that are formed at different temperatures on the steel as you heat is slowly for the second time that is why you need to polish the surface of the metal you want to adjust the temper of. Now just to throw a spanner in the works this part of the process is also known annealing and after the process of annealing the metal is then annealed. That bloody Brit speak makes things sound so dam complicated. When you have drawn the temper of the hard steel to let’s say “blue” to make the steel springy ( “good colour for “firing pins” ) the process I rapidly brought to a halt by immersing the steel in water or oil. Ken Jack Rowe’s method of drawing the temper works on the principal that the Oil flash point at a set temperature. So what he does is heat the steel to cherry red lets it cool give it a polish then immerses it in oil or lard then heats it until it reaches the flashpoint of the animal oil which is roughly about 300oC which is as you can see from the colour chart blue for spring and then quenches it in water. It does work for small springs and single leaf springs but large springs it will not work very well at all. The sand tray method does not need any oil Ken it just relies on the slow rise in temperature of the sand from the heat source which can be a gas burner or electrical heat source. The idea of the sand is that it is a poor conductor of heat (and Silver sand does not behave like popcorn snapping and banging when heated that is why it is used) so the oxide colours are formed slower and in consequence thicker making them far easier to see, when the colour you are aiming for is reached you stop any further heating by quenching in water. Now as silly as this may sound it is practically impossible to photograph the colours steel changes to when heated ken they are so subtle. I can only suggest that you obtain some 1/8 inch drill rod and try and make some springs your self.

Last edited by damascus; 05/16/15 10:05 AM.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Dec 2004

Posts: 997 Likes: 7

Sidelock

|

Sidelock

Joined: Dec 2004

Posts: 997 Likes: 7 |

I picked up some Gordon's Stump Remover, which is 99% Potassium Nitrate and 1% Calcium Stearate, melted it down and tried it for nitre blueing.

After melting and burning off, perhaps the calcium stearate, it was a nice clear liquid. I've experimented with it some at various temperatures and I get a sense, if, with a set up a bit less primitive than mine, where the temps can be controlled a bit easier, the stump remover would do the trick.

I've used a one burner propane stove, the kind used for deep frying turkeys with some expanded metal placed over the burner to set the nitre pan on and a cheap thermometer that registers 700 degrees.

I've done a few screws and pins for a Rem Model 11 and a beater German guild sidelock and both turned out nice particularly the German guild pins.

Last edited by Cameron; 05/16/15 09:51 AM.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Temper; (Webster)

[<AS & OFr <L Temperare]

1 - To make suitable, desirable etc by mingling with something else; moderate, as mingling criticism with reason

2 - To bring to the proper consistency, hardness etc by treating in some way; as to temper steel by heating & sudden cooling.

Thus the roots of this word "Temper" are far older than either us Americans or you Brits. The word itself describes the "Process" thus you "Temper the Steel", you do not "Give it a Temper", so there is No Temper to draw.

In most cases a piece of heat treated steel is thus tempered twice. The first temper puts it in its stage of maximum hardness, while the 2nd temper reduces the hardness to the level desired.

Now in America we do not normally refer to the hardening process as tempering only hardening. The second process we then call tempering. Is this 100% correct, I don't know for sure, but I do know it is far more correct than saying you "Draw the Temper" regardless of how long you Brits have used the terminology.

IE, You Brits did not "Invent" the word, only misused it.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Feb 2009

Posts: 7,734 Likes: 358

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,734 Likes: 358 |

I believe that was the purpose of the previously mentioned lead bath, evenness and consistency of tempering heat. Another thing that can come up with tempering is to hold the temp for some extended period of time can be a good idea.

The kiln may be a pretty good option, if you can monitor and control the temperature. If the kiln has uneven interior temps, which is likely, then placing the spring in simply a piece of pipe in the center can do the job of evening out the temp that treats the part.

Chances are if the spring breaks, at least part of it was too hard. It may matter if the piece got to the fullest hardness it could, to be able to temper it back consistently. Charts are easy to find for figuring out temps. Being able to judge colors can narrow temps down, but it may not be the easiest thing to figure out without a pretty good bit of practice.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,162 Likes: 256

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,162 Likes: 256 |

Piper you would continue this subject until our Henry VIII forgave Anne Boleyn for sleeping around. And as for the Webster when is has the same number of volumes as the Oxford dictionary I may take it seriously and it was a Brit who compiled the first dictionary was it not? And finally this site is for folks who are interested in double guns not the finer points of the English language for which I feel I do have a head start but as they say if correcting things floats your boat who am I to say you can’t!!!!!

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|