Dear Mr. Vicknair;

I wish you much success on this project; your finished work is very beautiful and your craftsmanship best quality. I have watched your work from a distance for a number of years and your skill and techniques are superb.

I started machining a new action body a few months ago to build another DR, and I believe that your estimate of total manhours of DR building is accurate. I complement you on using the sidelever along with a rising bite as the rising bite should work very smoothly with a side lever and make for a very strong breech section of the action. To my mind the use of a side lever will allow the design and building of a rising bite more simple and superior to the original design by Rigby.

The photo of the action you displayed shows very clean machining machining marks. Did you use manual vertical and or horizontal mills or do you have a high speed digital controlled machining center? I only have manual mills in my shop.

$50,000.00 just might cover shop overhead costs, but not contributing profit---a labor of love and investment in self education of best quality work.

On my next DR's I am going to build the barrels with shoe lumps. I have not done this before and am quite keen to do so. Have you used the shoe lump method to date?

Kindest Regards;

BV

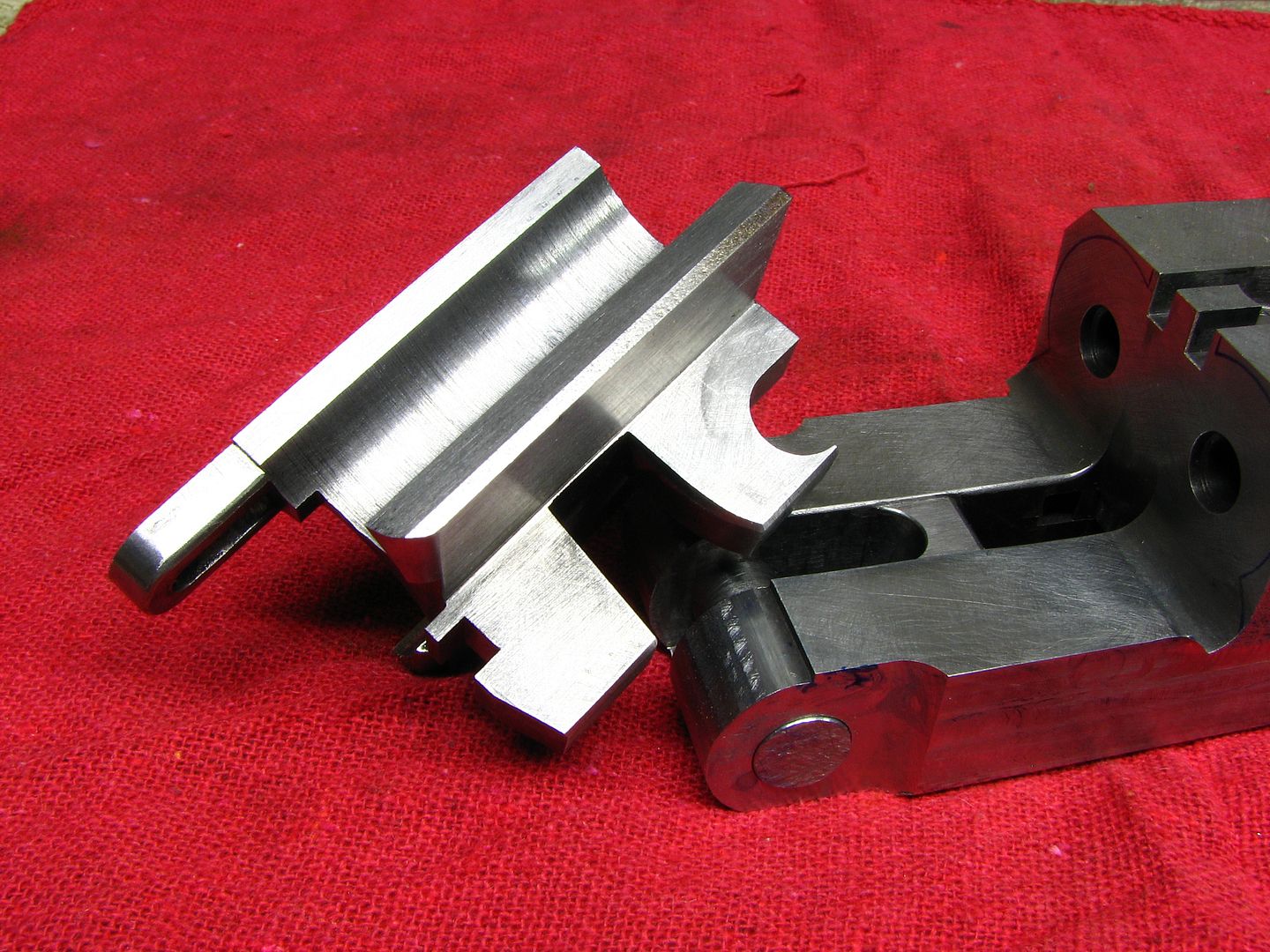

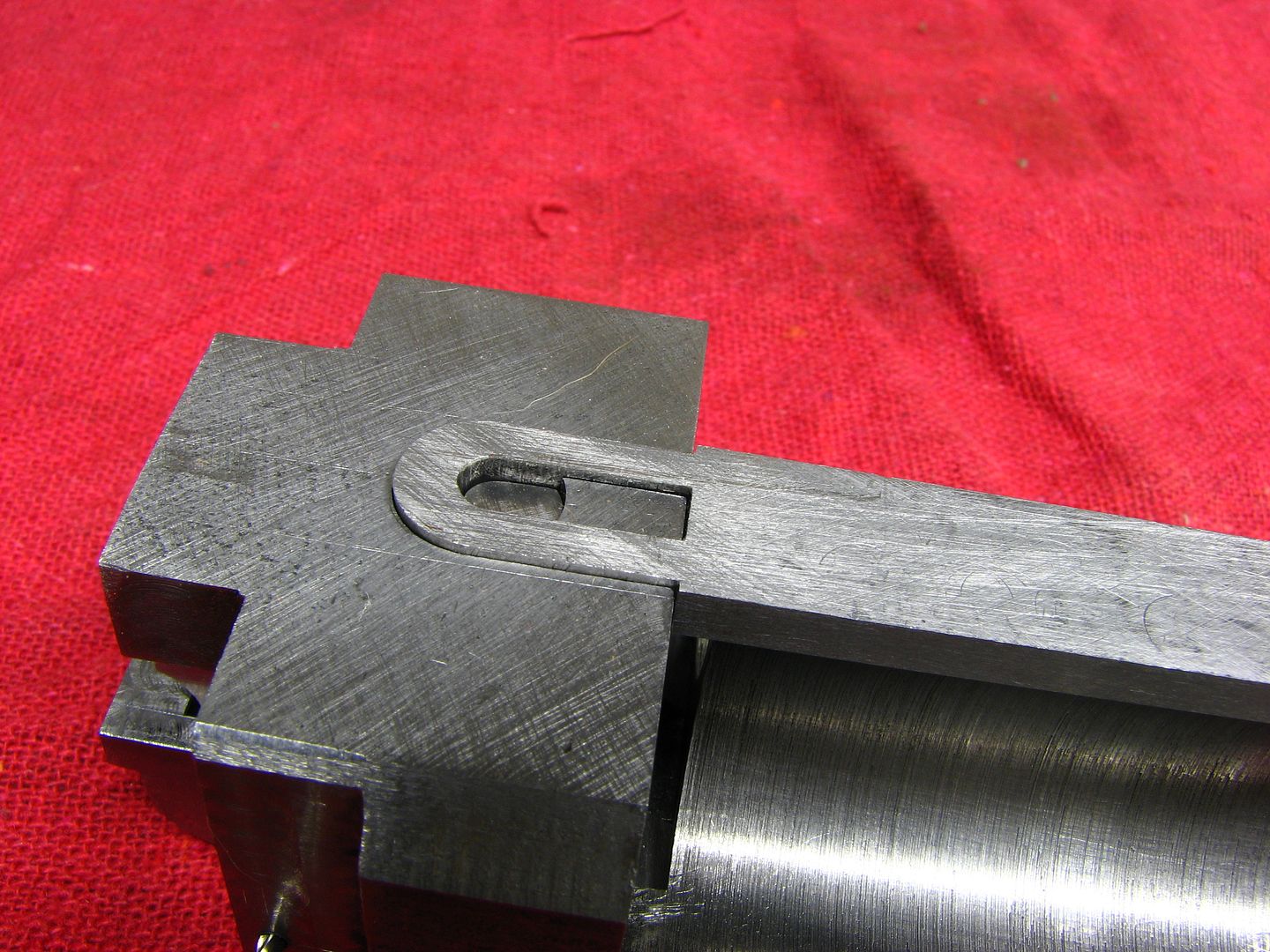

I'm actually going to use a combination shoe / through lump.

Here are a few photos of the lump. The extractor bore still needs to be machined. The first photo shows the chunk of 4140 that it was machined from. The front surface of the rear lump will bear on an hardened insert dovetailed into the frame.