Shortly after I got the Hoffman Martini some years back I tried Remington jacketed bullet .25-20 WCF ammo in it and the results were less than exciting. When I talked to Michael Petrov about this he gave me some 87 grain bullets from a Lyman 257420 (a gas checked bullet) mould and I never got around to trying them. When looking for loads, however, I found some extraordinary writing by Glen Fryxell on shooting cast bullets in this cartridge. It is posted on The Los Angeles Silhouette Club website at

http://www.lasc.us/FryxellCB25-20Win.htm and for anyone wanting to load for this cartridge it is a very good read and source of information.

When a .25-20 WCF chambering became a part of this Martini project I started looking for an Ideal 257283 mould based on Glen’s results with this bullet and eventually found one on eBay. This is the plain based earlier version of Petrov’s 257420 mould. This mould is part of the accessories that will be included in the project chest.

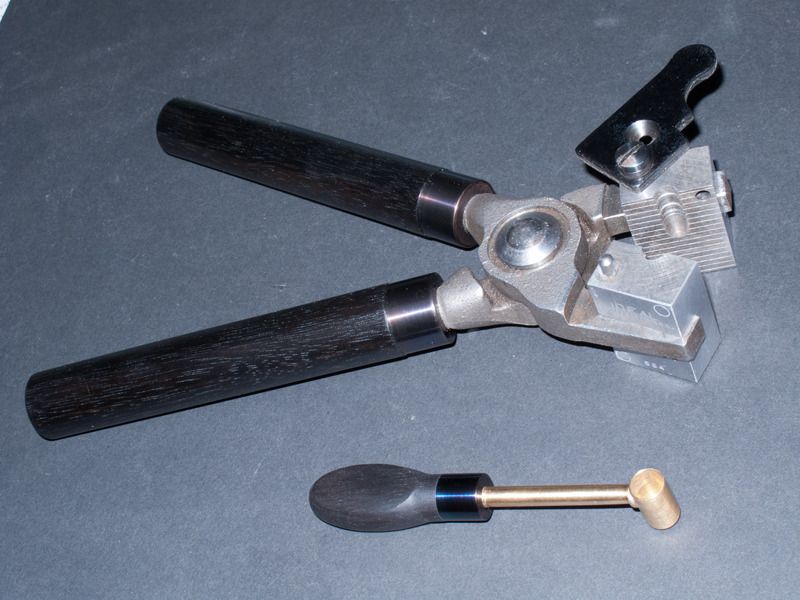

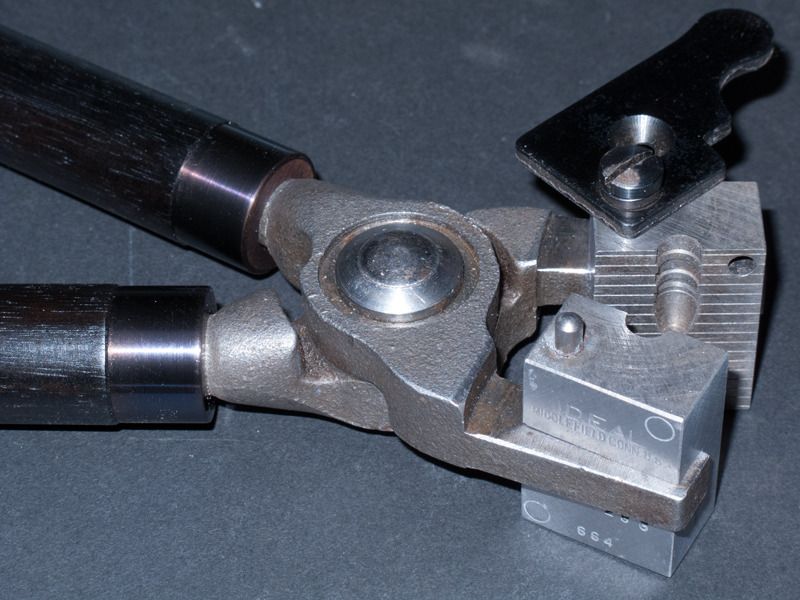

I got a small Ideal mould handle and took the wood off. Woodcraft had a sale on its Gaboon ebony and I got a 12” section of 1 1/2” square stock. It came totally encased in thick paraffin which set off a flashing yellow light in my head and after turning the stock round it was apparent that this was wet wood. Grasping the round stock sans paraffin I could feel wetness. Two days later it developed a lot of narrow checks which continued to enlarge for about a week. Surprisingly, two months later most of them had closed significantly and this week I turned two 6” handles, drilled and fitted them to the handles. The final diameter is around .860” and this is about the maximum diameter that the small handles will accommodate.

Here again is the photo of the parts including the NOE mould discussed later.

I turned ferrules from 1018 steel and nitre blued them. This is the parts before assembly.

Glen Fryxell’s preferred load for the 257283 bullet is 8 grains of 4227 and I made a measure for this capacity. It is brass, has an ebony handle and a 1018 nitre blued ferrule.

With the original Lyman 310 .25-20 Repeater tools, this completes all of the reloading accessories for the project.

A quick side note on 25 caliber lead bullets. Al Nelson of NOE moulds duplicated the 257283 mould profile for me and it is now available from him. I got a double cavity brass mould from him that I originally intended to be the mould for this project but it is too large by comparison to the original Ideal for the chest. The NOE mould casts very consistent and clean bullets and is of the highest quality and will be used for bullet production. The Ideal with the ebony handles will be reserved for the chest.

Footnote: The bore of the Hoffman was noticeably dirty and after a thorough cleaning is now bright and shiny and my expectations remain high for it.