Hi Michael,

hope you are getting on ok.

If you have too much time on your hands here's a time consuming project.

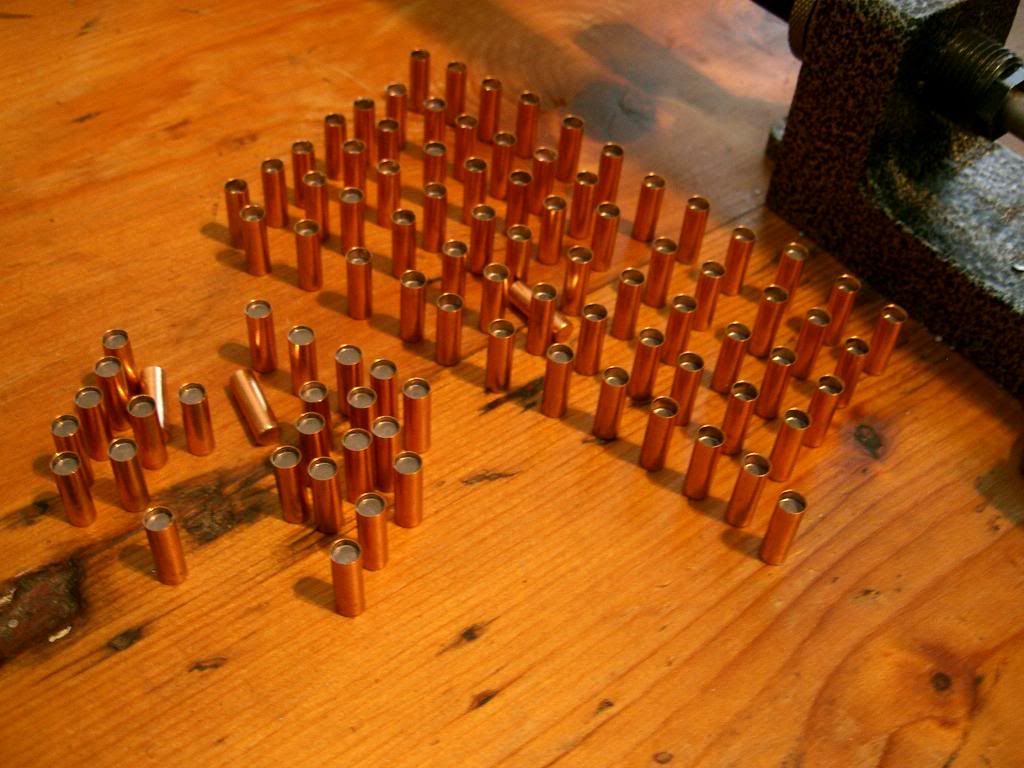

I make 22 bullets with Corbin dies and jackets, also make them with R/F jackets and thats even more time consuming.

My but I do have trouble posting photo's here. Got there in the end though.

Must make a note this time of how to do it.

The first photo shows swaging the cores, the second the cores in the jackets and the last one showing what happens to the seating die if you use too much pressure.

Best wishes, Roly.

[img:center]

[/URL][/img]

[img:center]

[/URL][/img]

[/URL][/img]