LB,

I was addressing only the lengthened cone tests, but you are obviously correct that he tested 2 3/4" shells in a 2 1/2" chamber first.

I had forgotten I had a somewhere acquired a pdf of ANSI/SAAMI Z299.2-1992,

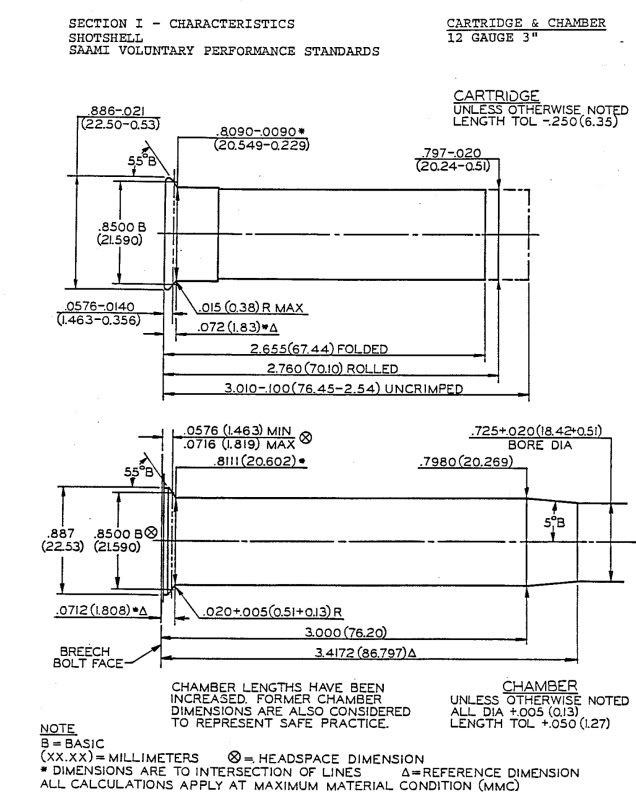

American National Standard Voluntary Industry Performance Standards for Pressure and Velocity of Shotshell Ammunition for the Use of Commercial Manufacturers. It shows a 5 degree (from bore axis) cone angle and a reference dimension that comes out to about a .417 cone length. The Blaser that Eyster tested and stated was a 2 degree cone angle would come out to about 1" long.

In my earlier statement about what I had tested, I mistated what I had tested. I tested standard SAAMI cone vs. approx 1 1/2" long cones and an approximately 4" (36 minutes of angle) long cone (not 3" as stated earlier),all in one 3" chambered 12 ga gun using 2 3/4" target shells. The 1 1/2" cone was cut with a reamer from Brownells, and the 4" cone was cut with a "taper-pin" reamer from a tool supply house and specially ground to fit inside the 12ga chamber by a professional cutter manufacturer who is a friend.

I have also tested an approximately 3" long cone in .410 3" chambers using 3" shells. I have tested at least 4 possibly as many as 6 separate .410 guns with before and after. I saw a benefit to the patterns.