Clap,

I had tried to separate any discussion about old barrels and their steel capabilities, since the properties are undoubtedly variable and somewhat unknown, within some educated guessing bounds. To be clear, I believe Bill is using a modern gun to take the measurements.

All,

That's where the

use of the strain gage data comes in. It's up to the user of data to apply it appropriately. The issue with these old guns is: we don't know exactly what each of our respective gun barrels is made out of, nor it's fatigue and strength properties. We, collectively, have some information on common cartridge pressures of the era for our guns. Then we are taking cartridge pressures we gather from whatever source and making a determination if we want shoot them in our guns. So, splitting hairs on whether a pressure value acquired is 7000 psi or 7500 psi is small potatoes when you consider that you don't know what your gun is made out of nor it's fatigue or strength properties, nor do you know how many cycles (firings) at what stress level has occurred in that gun (who knows how many SAAMI loads were fired before you got it?). It's all a WAG and therefore people should be conservative.

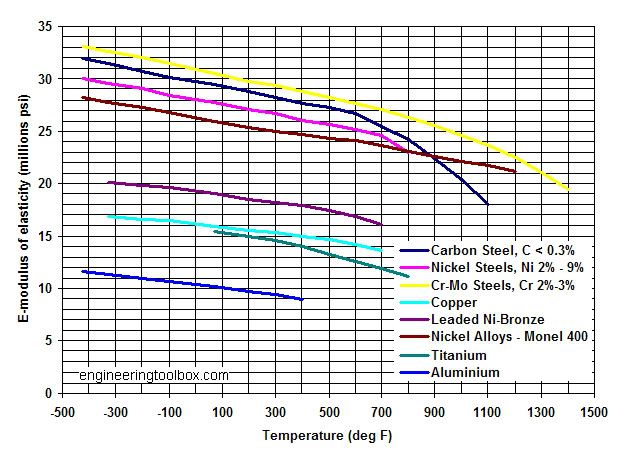

I didn't want to over complicate this discussion, but it's almost unavoidable to get into details. Here's a modern metals modulus chart. There is variation of steel, it's just small in the scheme of what it means to a stress calculation from a strain gage. I believe the device Bill is using, has built-in firmware which has accomodated chromoly steels common to guns of today. Since Bill's gun is likely a modern H&R single shot or similar, I'd say the device is probably pretty well set to give good data if the chamber measurements are done accurately.