Well, you are asking a good question. The methods kept changing over time and by country / region. Pictures are the best way to illustrate the process. As written descriptions become confusing.

Early on, some makers would incorporate used horse shoe nails along with cut up wagon springs, etc. This is basically known as skelp.

Then they would twist these rods together to add strength. Eventually they would wrap them around a mandrel to form a barrel. The "patterns" were difficult to control at best. But the British in particular had the skill to produce rather consistent patterns using this method.

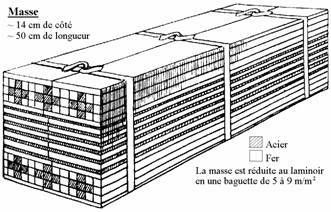

The "other approach" was to have the pattern formed by alternating layers of iron and steel. Eventually, these rods were produced solely by rolling mills. The rods were purchased by the barrel makers according to the orders they had for various quality barrels.

An early tool. The perrot used to twist the rods.

Belgian barrel makers with rods from the rolling mill.

A Belgian patent showing the layout of a rod that will produce a star damascus barrel.

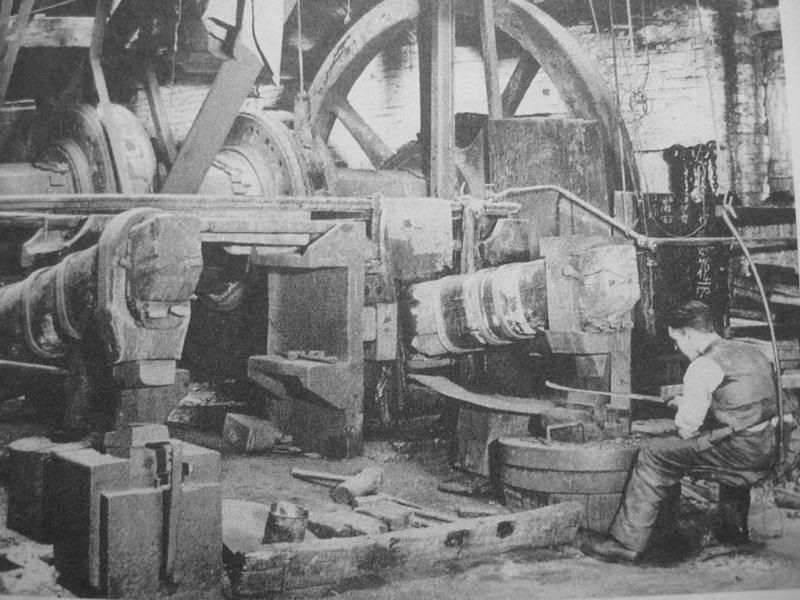

Belgian makers forge welding the rods around a mandrel.

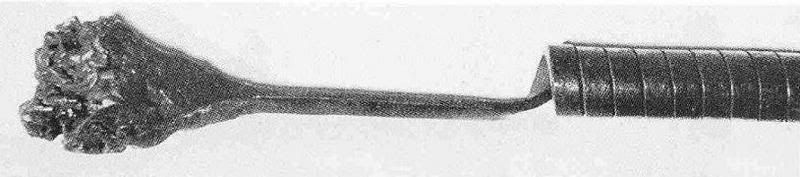

This is a barrel in process. You can see the chemise that protects the barrel from being welded to the mandrel.

Very early recreation a skelp barrel being formed.

Here you can see the skelp material. They would attach the horse shoe nails by welding them and then beating them into shape.

An English shop using a water driven trip hammer to form a barrel.

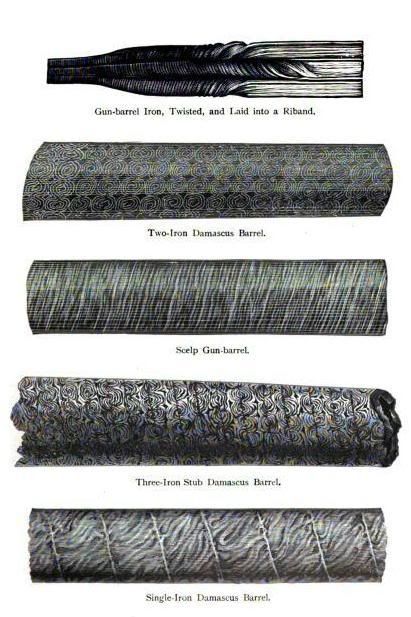

Some of the patterns from Greener's book.

I should add that these are very late methods, from about 1780 to 1930. The origins go back hundreds of years to Asia and India. There were early patterns produced in India that the European makers could never reproduce.

Pete