|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

4 members (SKB, Marks_21, Jtplumb, 1 invisible),

493

guests, and

4

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,846

Posts566,522

Members14,626

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Jan 2002

Posts: 7,726 Likes: 129

Sidelock

|

OP

Sidelock

Joined: Jan 2002

Posts: 7,726 Likes: 129 |

Almost all of my shotguns have mirror clean barrels, either because some one has kept them clean over the years or because somebody else had'em back-bored or honed&polished to clean up the pitting before I got them. Some of my guns have pretty thin minimum barrel thickness to show for being honed.

I have one old damascus Scott hammer-gun that is in good shape other than the for the bores being rather heavily pitted. I have shot it for a number of years with 'vintager' type loads and enjoy shooting the gun. I see no evidence that the gun has been previously honed, and the pitting looks old. I have kept it clean by burnishing the interior of the barrels regularly with a drill-turned bronze brush wrapped with 4 ought steel wool saturated in oil, and believe all the rust in the pitts is 'dead'.However, I know there is a possibility that some of those pitts do still harbor active rust, and that back-boring and polishing to remove the pitting would solve the rust question, make the gun look better, and it would be easier to clean the barrels. It would certainly improve the 'sale-ability'.

I also know that removing a few thousanths of steel will not make the barrels any stronger than they are now. My questions are: Should we be honing these old damascus barrels just for the sake of "pretty", or shooting them as they are (if in 'safe' enough condition, I know a pure judgement call) despite the pitting? Is there any appreciable pressure peak in the pitted areas that would cause special danger? Is the hoop strength of the barrels improved by haveing the bores smooth rather than pitted? What is your opinion of the minimum barrel thickness to which damascus barrels shoud be honed?...Geo

|

|

|

|

|

Joined: Feb 2004

Posts: 13,883 Likes: 21

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,883 Likes: 21 |

No, the hoop strength is not appreciably enhanced by smoothing the bores at the loss of wallthickness from honing. This is because the material in barrels is pretty malable with which along with goes resistance to notch fracturing. Besides, the higher stresses are on the outside of the barrel tubes.

My experience suggests that larger bore shotguns aren't as affected in their patterns from pitting as a very small bore (.410 being pretty susceptable to pattern problems from bore pitting).

|

|

|

|

|

Joined: Jul 2009

Posts: 69

Sidelock

|

Sidelock

Joined: Jul 2009

Posts: 69 |

I have been through exactly the same with my W J Jeffery sxs 410. Have had the action tightened but the bores are heavily pitted. Phil Smith at Bozards who did the action work was reluctant to clean up the barrels as in his view would be taking away metal and would need to take away a lot to get really clean barrels. His advice was just to keep on using it and one day either have new barrels or have the existing ones sleeved.

It seems to shoot OK and through decent patterns. But cleaning regime does have to be more through, and do store it with barrels well oil and muzzle down.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

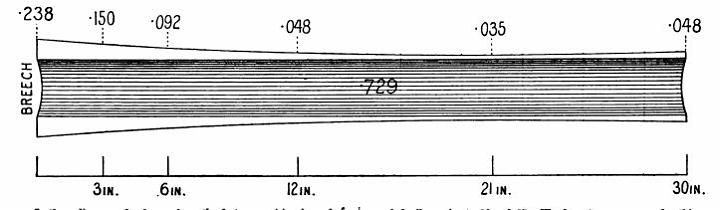

Geo, Chuck is spot on about not honing your barrels. Honing can make the walls dangerously thin. You can see the honing marks on this baker.  This is one take on minimum barrel wall thickness. You can see it varies as you move away from the breech. On the damascus barrels that I have measured, the breech is often not as thick as this illustration recommends. I have found a few where the breech was too thin for me. Recently purchased an beautiful bernard damascus gun that has a breech thickness of less than .10 at 3". It will never get shot by me.  Pete

|

|

|

|

|

Joined: Jan 2006

Posts: 15,465 Likes: 89

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,465 Likes: 89 |

Once a pit starts it's never going to stop growing deeper.

Might be okay to shoot forever like it is.

Myself I'd try and find a reputable smith to 'safely' hone them out or I'd sell it like it is.

|

|

|

|

|

Joined: Nov 2006

Posts: 3,483 Likes: 58

Sidelock

|

Sidelock

Joined: Nov 2006

Posts: 3,483 Likes: 58 |

OK, I'm not a gunsmith or engineer, but I do have some machining background, and some ideas on these barrels. Why not kill/remove the rust by carefully corking the muzzles, maybe with a bit of sealant (RTV silicone?) to prevent leakage, jig the barrels in a vertical position, and then carefully fill them with white vinegar for a couple of days? The vinegar will remove the rust in the pits. Flush the barrels thoroughly, run a wire brush with 4/0 steel wool through them to remove the discoloration and the sealant, then oil thoroughly and shoot forever. Just don't get any vinegar on the bluing.

|

|

|

|

|

Joined: Feb 2002

Posts: 364

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 364 |

Something else to try. Buy a pint or so of naval jelly and fill the bore. Let it stand for an hour or so and then do the other barrel. Stuff will get down to the very bottom of the pits and remove rust. Careful though, it will also remove bluing. If you then oil the bores after shooting those pits will never rust again. I've used the stuff on steel in a marine application and have been amazed at the results.

|

|

|

|

|

Joined: Jan 2002

Posts: 7,726 Likes: 129

Sidelock

|

OP

Sidelock

Joined: Jan 2002

Posts: 7,726 Likes: 129 |

Once a pit starts it's never going to stop growing deeper. That's gonna keep me awake at night, jOe! I may just try the venegar treatment; wonder if naval jelly would be easier to use and have the same effect???...Geo You posted while I was typing Nialmac. Might be the rust is all that is holding my "dangerous" damascus barrels together now!

Last edited by Geo. Newbern; 02/05/10 08:44 PM.

|

|

|

|

|

Joined: Nov 2006

Posts: 3,483 Likes: 58

Sidelock

|

Sidelock

Joined: Nov 2006

Posts: 3,483 Likes: 58 |

Naval jelly is a whole lot more expensive and no more effective. I can get white vinegar for $0.99/gal and I use it for de-rusting tools and saw blades that I pick up at yard sales. Works extremely well but leaves a soft black film on the metal, easily removed by scrubbing with ScotchBrite or steel wool. The naval jelly is also so viscous that it may leave an air pocket at the pit and thus won't attack the rust. Keep the vinegar off the blue, and oil the barrel interior as soon as it's clean and dry. I'd flush with hot water after draining the vinegar, kind of like cleaning up after black powder loads.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,883 Likes: 21

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,883 Likes: 21 |

Once a pit starts it's never going to stop growing deeper.Might be okay to shoot forever like it is.

Myself I'd try and find a reputable smith to 'safely' hone them out or I'd sell it like it is. I don't believe that at all. It's not bacteria, it's corrosion. A blackpowder gun may be a different animal due to the use of corrosive powder and difficulty in removing all the residue. The ideas for removal of the oxides (rust) on the surface should help alleviate the porous rust from retaining moisture and continuing to rust, but my smokeless powder guns don't have that problem. If you were intent on removing the rust chemically, use the Brownells rust and blue remover liquid. Personally, I see no reason to do anything other than clean and oil as normal.

|

|

|

|

|