Pattern Stock Construction: Below stock is being made for use as a pattern on the duplicator. Wood is a plain grain maple slab that has been air drying for 15 years. (My stockmaker friend started this pattern, but never got it finished) Note there is much more hand shaping and detail work yet to be accomplished on the pattern stock before it is ready for use on the duplicator! Once I have the pattern to my satisfaction, I will give it a coat of hard polyurehane paint so the tracing stylus will glide smoothly. This stock has 1-1/2 inches of drop and 3/8 inch of cast off for iron sight use. Rifle is a 404 Jeffery on a Brno 602 action.

Why maple for a pattern? It is nice strong wood, not too difficult to work, and I have a good supply. A lot cheaper than using a walnut stock blank for a pattern! I have slabs up to 3-1/2 inches thick, giving enough wood for more cast off if needed on future patterns.

I will be putting several hours of hand detail work in the final shaping. Once it is completed and epoxy coated, it will be fairly durable and may be used for many stocks. Is there a "Special" waiting? Yes, two, a 450 Rigby for myself and my buddy's 404 Jeffery.

This one has a long pull length, both my gun buddy and I are big blokes: My length of pull is 14-3/4 and his is 15. I plan on making another CZ550/Brno 602 pattern with a slimmer cheekpiece of more pleasing shape.

Length of pull is adjusted on the duplicator by using a longer blank for the final stock, and attaching a butt shim to the pattern. Or, if a shorter pull is needed, just trim off the excess on the final stock. The final stock may be made slimmer or thicker by adjusting the cutter depth in relation to the stylus depth.

In the below photo I have placed a hard epoxy mix in the barrel channel, coated up the barreled action with release agent, and clamped it for a 24 hour cure. Barrel is a No. 6 contour, chambered for 404 Jeffery. Next step is a little more shaping of the stock, sanding, and painting with the polyurethane paint. Then off to the duplicator to make a stock for real.

In answer to one of the questions, a pattern will last forever, although it may need a little maintenance from time to time. And sometimes the pattern is modified slightly to better fit another shooter. This is where the Bondo and other epoxies com into use. This pattern stock has a realy long butt, so after the final stock is carved, any length of pull is available just by the usual trimming prior to installing the pad.

One advantage of the stock duplicator is the dimensions for the final stock may be adjusted by changing stylus size respective to the cutter size, and by the adjustment of the cutter in the collet. For more wood, use a cutter smaller than the stylus, and adjust the cutter to a shallower depth than the stylus. Same thing in reverse for less wood.

Here are photos of the final shaped and sanded pattern stock, and photos of some of the epoxies I have been using. The stock photos were taken with a wide angle lens, so the stock looks out of proportion; it is longer and slimmer than shown. I left wood in the cheek piece and butt, to alloy for final shaping to fit when an actual stock is carved.

Below three are of the stock, you will note I have used several epoxies for filling and shaping. The white is good old SuperMend, a two part White epoxy for general purpose mending, I bought it in a marine hardware store. Similar to Marine Tex. A little hard to shape. The cream color bedding in the barrel channel is the epoxy tile grout I mentioned earlier. I had some left over from a bathroom tile job. I omitted the sand filler and used fiberglass flock to obtain a desired consistency. More on this later. The dark brown is the same epoxy grout, but with brown stain (Brownells for Acraglas) mixed in. The light tan (almost the same color as the stock wood) is good old automotive bondo. I used all three to show that just about any good epoxy may be used in stock work.

I will be painting the stock tomorrow, more on the paint later.

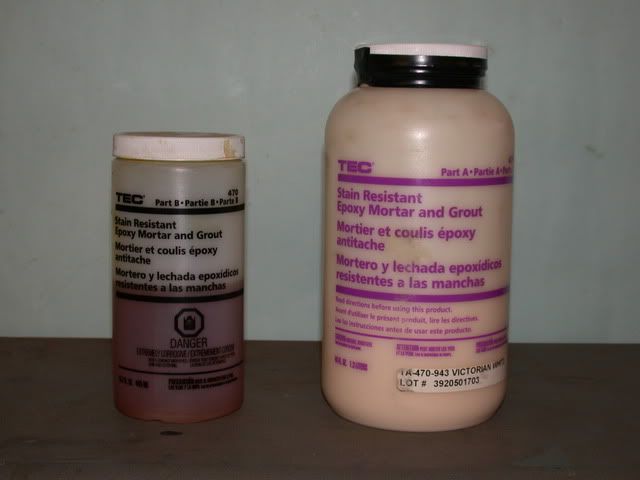

Below is the epoxy grout. It comes in a kit with fine silica sand, this is used when grouting tile, just mix it in. I leave the sand out as mentioned above. But sometimes I will mix the sand in the epoxy for the recoil lug areas on big bore rifles. Buy it at an industrial tile supplier. I had some in a cream color, but it is available in many colors, or you can dye it as mentioned above.

Below is another product that may be used for bedding stocks, basically works the same as the epoxy grout above, and comes with fine grain silica sand. Marketed by Loctite, so it is real expensive. Good stuff though. That is a gallon can of resin, so it will last me to my grave. But it at an industrial supplier, mine came from Kaman.

Below is the black polyurethane paint I use for fiberglass hunting stocks. It is a two part catalyzed mixture, sort of a tough product to work with, and has enough warnings such that it could have been used in WWI instead of Mustard Gas. The gallon can on the left is the thinner for cleaning the paint gun and for thinning the spray mix. The texture may be varied by thinning for a smooth surface, or no thinner and letting the mix partially cure for a pebbled surface. Real expensive stuff, very hard to find. Extremely tough and last a long time. Gives a deep matte finish black. The thinner is real bad and will eat up just about any plastic or paint, so do not use it to clean road tar off your Rolls Royce!!!!