|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

0 members (),

313

guests, and

4

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,839

Posts566,361

Members14,623

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

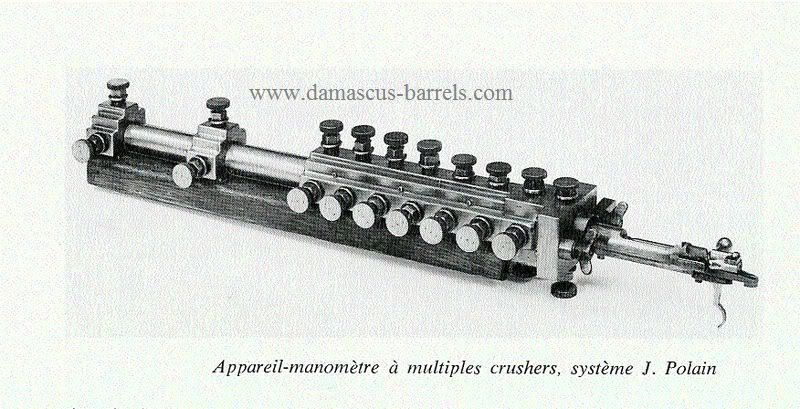

Jules Polain became the director of the Belgian Proof House in 1890. He developed this gauge by 1900.  Notice the placement of the crushers. So what prevents this from being duplicated using modern strain gauges? Nothing except the expense. That really is what is being said when a manufacturer talks about placing 1 strain gauge at X inches..... If a maker wants to know what is going on, why contract Bell? Why not go to the best around HP White http://www.hpwhite.com/ ? Do not get me wrong. I use Gaugemates, etc. But I do not believe they have any impact on barrel pressures. They will not allow me to use 11,000 psi loads in a 100 year old gun built for 7,000 or 9,000 psi loads. I just purchased this Ithaca 10ga. It will get a diet of only black powder and RST low pressure ammuntion.   Pete

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 15

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 15 |

There would be no reason for chamber pressure to be any differrent in a chamber reducer than in a chambered barrel. I would very seriously doubt that the barrel chamber walls are REQUIRED to absorb any stress from the chamber pressure; the reducer should be capable of being fired without damage outside a barrel. Depending on the tightness of the fit between the reducer and the chamber, the barrel might strain as part of the reducer-barrel system.

When the wad transitions from the reducer to the barrel bore, there should be a pressure drop. So, chamber pressure should be normal and barrel pressures lower.

There is no reason that strain gauges can not be glued all over a barrel; gauges are cheap. However, measuring/recording equipment is not cheap. Operating mulitple channels is expensive. To get good data with a single channel set-up would require the repeated firing of statistically significant numbers of shells for the various locations.

If one really wanted to measure the chamber pressure of the reducer-barrel system with a gauge on the outside of the barrel chamber area, one would need to run a series of known calibration pressures. One way this could be accomplished would be to seal the barrel in the front area of the insert and subject the system to static hydraulic pressure measured by a known accurate pressure gauge. Strain gauges further down the barrel could be calibrated by this method, taking care to seal the barrel such that no part is subjected to above design pressure. Such a system would allow measured pressure-displacement curves.

All it takes is time and money!! The know-how is there.

|

|

|

|

|

Joined: Jul 2006

Posts: 1,164 Likes: 11

Sidelock

|

Sidelock

Joined: Jul 2006

Posts: 1,164 Likes: 11 |

A basic scientific law is;'Every force has an equal and opposite force". In the case of any gun/rifle the opposite force to that created by the detonation of the cartridge/shell is the recoil we experience.I would expect that the weight of your 10G complete with Chambermates is heavier than your 12G. This being the case you will experience less recoil with the heavier gun for any given shell.Another factor that can influence recoil is cartridge head space, if excessive this could be another reason for increased recoil experienced with your 12G. In so far as velocity is concerned, once the charge leaves the confines of the 12 G Chambermate and enters the 10 G barrel, velocity may be reduced due to the increase in bore diameter/volume. It would seem logical that a 12G wad would not be an efficient seal in a 10.G bore[ie;diameter increase is.046 inches] Perhaps Chambermate has carried out tests to determine the impact on velocity as the charge enters an over size barrel?

Roy Hebbes

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 15

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 15 |

Roy, it seems that modern plastic wads will, indeed, make a good seal in a larger bore than might seem reasonable. The reduced pressure is pushing against a larger wad base. Payload acceleration, which determines muzzle velocity, is controlled by force on the wad base. This force is the pressure times the wad base area; smaller pressure times larger area equals similar accelerations. I am yet to see conclusive data on comparisons of velocities, though. Market acceptance of chamber reducers would indicate reasonable performance.

|

|

|

|

|

Joined: Aug 2005

Posts: 180

Sidelock

|

Sidelock

Joined: Aug 2005

Posts: 180 |

I don't think anyone has done any tests to find out the impact on the velocity of the charge at the INSTANT it enters the larger bore, but most certainly they have done tests to determine the impact on the velocity at the muzzle. Their initial tests showed an actual slight INCREASE in muzzle velocity with a particular load that was fired in a sub-gauge reducer/larger bore barrel combination vs. being fired in a nominal gauge barrel. They were uncomfortable with the data they collected because it was, as you indicate, counter-intuitive, thus their decision to hire Bell to confirm or nullify their data. His tests showed the same resulting slight increase (or at some times no change) in muzzle velocity. While it would SEEM logical that a 12 ga. wad would not be an efficient seal in a 10 ga. bore, the only data available at this time indicates this isn't the case. I asked if they had a theory as to how you could get even a slight increase in velocity, and they did, but my memory is a little unclear on what they said - suffice to say I was a little doubtful of their idea although I certainly don't have a better explanation. It had something to do with a decrease in total friction of the shot column against the bore as the shape of the column expanded and shortened upon entering the larger bore (if I remember correctly).

Last edited by vh20; 10/13/09 12:27 PM.

|

|

|

|

|

Joined: Feb 2008

Posts: 11,899 Likes: 748

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,899 Likes: 748 |

It (almost) stands to reason that the moment the wad seal is broken by leaving the Gaugemate chamber and entering the larger bore, the pressure should fall off. Velocity would be affected as well with slower burning powder presumably having the most loss since peak velocity would normally be achieved futher down the bore. The kickers, in my mind, are the phenomena we see sometimes with reduced loads producing pressure spikes or detonations. What might happen with a static pressure produced by hydraulic oil or inert gas perhaps, could give dramatically different results with different powders and loads. It seems the companies that produce the reduced gauge chamber inserts have the vested interest in proving their devices may make a marginal gun safer to shoot by reducing pressures while maintaining decent velocities, or perhaps supressing data that may show negatives. It's hard to believe they put these things out there without having tested these areas of potential liability.

Voting for anti-gun Democrats is dumber than giving treats to a dog that shits on a Persian Rug

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

I believe that one of S. Bell’s articles showed that the pressure peaks when the shot column has moved less than an inch and it is on its way down by the time the wad clears the shell mouth.

This would be within the insert, how much the insert adds to the barrel strength would be hard to say.

VH20; My remarks about the 1.00" pressures were in responce to this. That fact was of course well known & proven before Bell was born. Certainly placing a strain gage at the 1" point over a chamber with an adapter inside whould show little or nothing as to what the pressure inside the adapter would be. "IF HOWEVER" the purpose was to determine the relationship of "BBl Pressure" At least Three guns should have been tested. first a 28gauge itself, then the 12 & 16gauges Both having the same chamber lengths & as near as possible to same length cones. The strain gages should have then been placed the same distance from the breech in all cases & the same lot of shells fired for all three tests. Lacking these parameters then I believe my statement regarding the Guernsey vs the Hampshire are still Very Valid. I ask then What in Fact did we learn from this test. "IS" it reasonable to deduce the pressure is higher in the bigger bore "OR" is it more likely this was simply becauce it was taken Closer to the breech. Looking at available pressure curves once the peak has passed, within the chamber itself, we see a falling off from there forward. "IF" the presure had been recorded at that same distance ahead of the end of the case in 12, 16 & 28 gauges what would it have read in all three. Personally I would expect it to be highest in the 28, next the 16 & lowest in the 12. If you are totally honest about it I think you would have to agree this was not proved to be otherwise.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Aug 2005

Posts: 180

Sidelock

|

Sidelock

Joined: Aug 2005

Posts: 180 |

Thanks for the clarification, Miller. I puzzled over the statement as written, especially coming from you, but without your supplied reference it didn't make sense and now it does.

Regarding the rest of your last post, I agree completely with each of your points regarding the best test practices, and lack of conclusions that can be drawn from the practices used. However, I don't think that the answers that we are trying to divine from the data are necessarily the ones that the manufacturer was after. Their primary interest is in showing that 1)There is no significant degradation of patterns with the use of their subgauge adaptors, and 2)There is no significant reduction in velocity with use of same. When they tested it themselves they got data that showed actual INCREASES in velocity around the order of 100 fps. That's when they decided to have someone else run the tests. I suspect the decision to measure pressure was of secondary importance. Nowhere has the manufacturer ever mentioned use of their product for older guns with lower pressure requirements, so I don't see that as being the purpose of the tests (but of course we would all love to know). Bell mentioned in the letter the problematic nature of getting the strain gauge in the same location for each barrel, but I don't fault him for not finding a solution if that was not in the client's specified interests, but it is disappointing for us. I agree completely with your deduction that the reason the 12/28 AA combo showed higher pressure than the 16/28 AA combo is for the reason you state - it was measured closer to the breech, and a crappy way to determine what we are discussing here. But Bell did not state any conclusions that there was an inherent pressure increase related to the bore size. He merely stated his methods, their problematic circumstances, and reported the raw data. This was sufficient for the client's purposes, but inadequate for ours, and we are left to draw our own conclusions. He satisfied the client's curiosity about whether or not the slight, and unexpected increases in muzzle velocity were real or the result of a fault in the manufacturer's own tests, and that was all they wanted.

What we don't know is if any other data points were constructed. My opinion, based on a dim recollection of a conversation with him over 2 years ago, is that almost certainly there were, and likely some of the very ones we'd like to know. If so, whether or not Sherman reported them to the client, or the client edited his report is the next logical question. In any case, we do not know for sure. Regardless, neither Sherman nor the manufacturer have stated any conclusions that pressure is either routinely higher or lower when using subgauge adaptors. Pressure has been treated more or less as a sideshow to the importance of velocities and patterns, and no conclusions about it are stated.

You stated that you would expect it to be highest in the 28, next in the 16, and lowest in the 12, and that if we are intellectually honest that this was not proven otherwise. In response I would state that it would also be expected that the velocities would also decrease, however slightly, in that same order, but the tests show otherwise - in fact they increased in some cases. That doesn't disprove your expectation, nor do I claim that you aren't precisely correct. However, if we are being intellectually honest, it would be very difficult for velocities to stay the same or increase if there was any SIGNIFICANT decrease in pressures, given that the load didn't change. All that Sherman stated to me was that there was no SIGNIFICANT decrease in pressures with the adaptors that would warrant any claim for their use as a safe way to use a subgauge load that develops pressure (in it's nominal gauge) that you would not want to put through the parent barrel with its own nominal gauge load of the same pressure. I think there IS enough data here to draw that conclusion (only). Anything beyond that is certainly Guernsey vs. Hampshire.

Last edited by vh20; 10/13/09 09:20 PM.

|

|

|

|

|

Joined: Mar 2002

Posts: 1,815 Likes: 4

Sidelock

|

Sidelock

Joined: Mar 2002

Posts: 1,815 Likes: 4 |

I have also had quite a few failures in ignition with 7625 in a 10 ga. I am in the same opinion and not use anything slower than Pb or Greendot. I have not had that problem in a 12 ga, but have not been less than about 50 degrees using it.

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 15

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 15 |

As I noted earlier, the muzzle velocity is a product of the pressure - displacement curve times wad base. Higher muzzle velocity from a larger bore barrel using a chamber reducer simply means that the wad base area increased more than the pressure decreased. That is, the powder charge was more efficient in the larger bore. This is, to me , slightly counter-intuitive, but not at all unbelievable. If solid data says it is so, then I accept that it is so.

I doubt that barrel friction enters into this issue. I showed not too long ago that the expected frictional forces are trivial when compared to the wad base forces.

|

|

|

|

|