|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

|

|

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

|

|

|

|

|

|

|

|

|

2 members (welder, R. Glenz),

402

guests, and

4

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,607

Posts563,339

Members14,600

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

OP

Sidelock

Joined: Nov 2005

Posts: 4,598 |

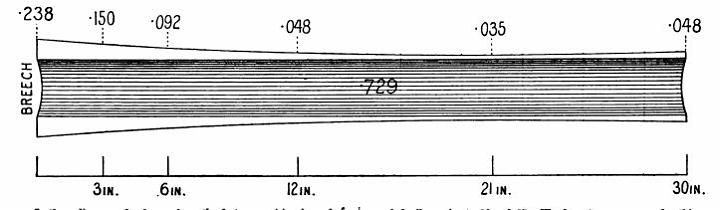

Thought I would add this. I forget the source, but I believe it is circa 1900.  Pete

|

|

|

|

|

Joined: Jan 2002

Posts: 782

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 782 |

By the "I'm willing to assume blame for reloader error" comment, I assume the ammo in question was reloaded.

To me, this looks like an ammunition problem instead of a barrel metal integrity problem.

I would immediately condemn the ammo from that loading batch and ALL ammo subsequently reloaded in that facility since that date until the matter is resolved. The condemned ammo should be labeled and isolated from other ammo.

If I had to guess, I would speculate that: A. a much "faster" powder than normal somehow got into the reloading process, or B. that a greater than specified powder charge was somehow introduced into the case and the greater volume was not noticed during the initial and final crimp stages.

Was this ammo reloaded on a single stage machine or on a progressive machine?

|

|

|

|

|

Joined: Mar 2002

Posts: 1,815 Likes: 4

Sidelock

|

Sidelock

Joined: Mar 2002

Posts: 1,815 Likes: 4 |

Sure looks like a 20,000-25,000 psi load to me with the metal flow into the extractor cut.

|

|

|

|

|

Joined: Sep 2003

Posts: 257

Sidelock

|

Sidelock

Joined: Sep 2003

Posts: 257 |

No evidence of pitting???

Then what are the crater like depressions that I see in #10 #12 and #14?

Mark

|

|

|

|

|

Joined: Feb 2003

Posts: 1,116 Likes: 1

Sidelock

|

Sidelock

Joined: Feb 2003

Posts: 1,116 Likes: 1 |

JOe, Yes,I see where your comments are directed. My response was on the examination of the gun prior to shooting it. The section your referring to, I assumed was the scorching of the blast. Looking at it after the fact didn't raise any red flags. My concern was the tooling marks present in the bore. I gave the barrel to a friend in OHio and will refer to him to reexamine the area you describe. Looking at the photos it looks to be pitted as you said. I'll have Terry look it over. Now to the other questions: Reloaded ammo on PW progressive press.Reload was STS hull,Clays powder,1 oz, believe windjammer or CB equiv.wad, 5800psi. Brother and I went over that press, time and again to see where any steps that would allow for a double charge but unless a purposeful act it seems unlikely. Glen went over and cleaned all press components after the incident and we went on using the same load with no other mishaps. We took apart the remainder of the loads in the box and all were on the money for powder wt. etc. We settled on that load years ago and have not changed except this past year went to 7/8oz shot when prices went up and I think we'll stick with it, It shoots good.

RMC

|

|

|

|

|

Joined: Jan 2002

Posts: 782

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 782 |

RMC: Looks like you and your bro gave this incident a hard look.

Even given your investigation, I still think this is an ammo problem.

In a worst case scenario, if a seriously pitted chamber area of the barrel DID LET GO, that still would not account for the indications of over-pressure on the cartridge case. One would expect that the pressure vessel would be venting the pressure even more rapidly with a fracture or vent in the chamber wall, and that the pressure would drop more rapidly than normal. Hence, how could there be MORE pressure than normal evident on the cartridge case?

Good luck in your continued investigation. I hope to learn something from this incident, as I "roll my own" also, but on a PW 375 single stage loader.

|

|

|

|

|

Joined: Feb 2006

Posts: 3,854 Likes: 119

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,854 Likes: 119 |

The metal near the blow-out looks to me like it is crystalized, almost like "white metal" in that area. The metal doesn't look soft but hard. And the way it broke cleanly near the begining, like it had been hardened, didn't peel or unravel like the way it was formed.

David

|

|

|

|

|

Joined: Jan 2006

Posts: 15,465 Likes: 89

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,465 Likes: 89 |

I'm betting on a double powder charge....the area that blew could also have had a deep pit.

Once a pit starts in Damascus whats to keep it from following the twists and turns of the Damascus ultimatly finding an original flaw in the pattern weld.

|

|

|

|

|

Joined: Dec 2001

Posts: 884 Likes: 1

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 884 Likes: 1 |

Hello

I shot benchrest for alot of years and when you shoot hot loads you learn to read primers and cases.

Pitting or no pitting that didnt couse this problem.

Your shell was very hot.....I dont think an 870 would have held up to this pressure.

I can think of 3 things that could have happened.

1 double charged

2 wrong powder

3 base wad in barrel from the shot before.

These are all thaings that could give you that high pressure. The case tryed flowing into the extractor and the primer flowed around the firing pin.

Bob

Last edited by Bob Noble; 12/10/08 09:40 PM.

lefeverarms.com

|

|

|

|

|

Joined: Mar 2002

Posts: 7,893 Likes: 652

Sidelock

|

Sidelock

Joined: Mar 2002

Posts: 7,893 Likes: 652 |

Looking at the shell it looks like a classic high pressure problem. Primer and base both show major deformation. I doubt that you changed powders and cause it. Light loads do have a lot of extra space in them, but you would expect to see a major overload. But even if you can not accept that it was a load problem, it was. Barrel failure would not have caused the primer cratering, or the rim to deform like that. Only increase pressure causes metal to deform not the sudden release of pressure by a barrel failure. Rule out powder substitution by cutting open shells to check for uniform powder weight and type. UNles the loads were shot in extreme cold I suspect shell failure not gun failure. Extreme cold can cause weird powder burning sometimes.

You hit upon the most likely reason for the failure. Reloader error. Not you, but the machine. Not here to trash PWs. Great machine, but not absolutely fool proof. I know that all reason and logic tells you the PW is fool proof, and can not drop a double powder or a load and half powder in any shell and get it to close. Been there and done that as they say. It does happen and can be done in light loads easier than regular loads.

If you want a like new PW 900, in 20 ga., go to the East bound Route 50 bridge, over the Chesapeake Bay, dive off the south side, into the shipping channel and you will find my old one. Once every thousand shells I would get what was a very heavy overload. Not a true double powder drop maybe, but a load that would loosen those back fillings. I sent the machine back to PW two times to have it gone over and checked. They claimed to have rebuilt and checked every part on a machine that had not loaded 10,000 shells. Sent it to a PW seller who knows more about PW's than the factory. Lent it to a buddy for a month, until it did it to him. No one ever figure out what, or why, or even how it did it. But three different people, had that machine do it to them. PW assured me the problem was operator error until all three of us explained that the machine did the same thing for us. They refused to admit that a problem existed and could not repair it to prevent it from occuring again. They did take several hundred dollars of my money for "repairs" and "shipping cost" were several hundred more.

Now I did not throw the machine off the bridge because I was mad. I did it because I never wanted anyone else to use that machine again and have the same problem. I shot what must have been proof or above proof loads multiple times without a major gun disaster. But I was luckier than a IL politician with a tape machine turned off. I tossed a few hundred dollars away and never been happier. Best news for you is that it sounds like your son was not hurt. Sorry for the gun loss.

|

|

|

|

|