|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

Forums10

Topics39,768

Posts565,405

Members14,618

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Dec 2001

Posts: 7,381 Likes: 700

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,381 Likes: 700 |

Firearms imports, consignments ![[Linked Image from i.imgur.com]](https://i.imgur.com/Ez9oz9Rl.jpg)

|

|

|

|

|

Joined: Aug 2004

Posts: 865 Likes: 76

Sidelock

|

Sidelock

Joined: Aug 2004

Posts: 865 Likes: 76 |

Daryl my email is down but this is what I have,...the top one is the southgate type and you will get a pair from that blank You might also want to give these people a call CJ http://www.josephbrazier.com/history.html

The taste of poor quality lingers long after the cheap price is forgotten.........

|

|

|

|

|

Joined: Dec 2001

Posts: 6,506 Likes: 376

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 6,506 Likes: 376 |

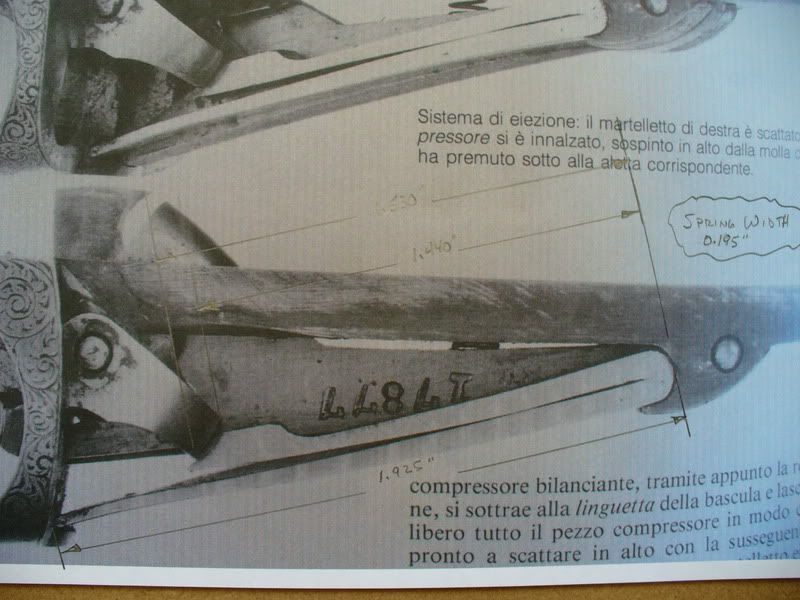

SKB is correct, Helston will not export. C.J. that is an interesting spring setup. I suppose it is common for gunsmiths, but I have never seen it before. Here is more info on my gun with some dimensions for the springs needed. This is my gun----------  This is a similar gun with the dimensions of my gun added.----The dimensions, from top to bottom are 1.530", 1.440", and 1.925". Spring width is O.195".--------

Last edited by Daryl Hallquist; 10/19/08 10:38 AM.

|

|

|

|

|

Joined: Jul 2005

Posts: 2,429 Likes: 35

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,429 Likes: 35 |

CJ, Don't take this is any way as a critique; Seeing springs cut out of solid bar stock like that goes completely against all of my springmaking sensibilities! I think of springs as forged and bent with the grain running the length of the flex.

These look like an extraordinary waste of material with all the wrong grain structure. Are they pre-hardened and tempered?

Now, I've got to admit I used investment cast steel spring in building and shooting flintlocks for a couple of decades, and I can't ever remember a Siler mainspring breaking! Siler being the most popular flintlock ever made, original or reproduction.

But what an advantage for making/replacing a spring! Modern metalworking is genuinely beyond my ken....

|

|

|

|

|

Joined: Dec 2001

Posts: 3,971 Likes: 105

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,971 Likes: 105 |

Steve, I've had Jud Brennan hand forge a number of springs to replace the cast ones on my Silers and the difference is remarkable in smoothness of the hammer and frizzen throw. I do have to agree that a well cast spring from the proper metal is pretty reliable.

John McCain is my war hero.

|

|

|

|

|

Joined: Aug 2004

Posts: 865 Likes: 76

Sidelock

|

Sidelock

Joined: Aug 2004

Posts: 865 Likes: 76 |

CJ, Don't take this is any way as a critique; Seeing springs cut out of solid bar stock like that goes completely against all of my springmaking sensibilities! I think of springs as forged and bent with the grain running the length of the flex. So did I Steven,…until I tried it. A couple of these have been in service for some time now with excellent results. It all started with the small spring you see in the picture, the one with the pin hole. I had a high quality French double with a broken top lever spring, I looked for a replacement for quite some time but had no luck,...nothing ever came close and since I didn’t feel like making one from scratch I decided to give this a try,…the method is not new, I talked to the manager of a heat treating firm here and was told that springs of similar design but used for different applications are regularly wire cut,…he also provided me with the precise heat treating instructions for the steel I used,…. have also heard from a reliable gun making source that one of England’s top shelf makers may be making springs this way as well. Investment casting offers no particular grain structure and a well cast spring will do it’s job, I believe that this method will yield superior springs than could be had by casting, not to mention the versatility to do any shape and size desired I drew the shapes in CAD, using the existing springs for reference making sure perfect tapers were maintained, that’s the beauty of wire EDM,… it’ll cut exactly what you draw. Wire cutting is not cheap and most shops that do it wouldn’t bother with a small job like this so I had to cash in on a couple of favors,…the steel is soft O-1 and there is about a grand worth of machine time there with three different spring types,… if I had to pay someone to design and draw it all it wouldn’t have made any sense…but since it didn’t cost me anything I look at it as a successful learning experience CJ

The taste of poor quality lingers long after the cheap price is forgotten.........

|

|

|

|

|

Joined: Aug 2004

Posts: 865 Likes: 76

Sidelock

|

Sidelock

Joined: Aug 2004

Posts: 865 Likes: 76 |

Daryl, this spring will work just fine, the blank is almost wide enough to get three out of it and the length will accomodate your numbers with a few thou to spare,...just remember you will need to cut , harden , temper and fit this,...and timing the ejectors probably being the most difficult part.

CJ

The taste of poor quality lingers long after the cheap price is forgotten.........

|

|

|

|

|

Joined: Jul 2005

Posts: 2,429 Likes: 35

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,429 Likes: 35 |

Joe, Thanks for the insight, I was refering to the durability of cast springs. I'll bet Jud can forge for improved geometry and function.

I never ceased to be amazed CJ! Not only do you understand and perform excellent handwork, but CAD and modern manufacturing techniques as well!?!?

EDM "wire" cutting is one of the more aptly named processes; I envision a micro-jeweler's saw blade hard at work. I'll bet they work like a charm. After (in the case of the ejector spring) the many hours of gunsmithing required to cut, fit, harden, temper and tune them.

Great photo too!

Thanks, Steve

|

|

|

|

|

Joined: Aug 2004

Posts: 865 Likes: 76

Sidelock

|

Sidelock

Joined: Aug 2004

Posts: 865 Likes: 76 |

Steven,...here is a set of Lefever ejector hammers I made last year,...was a lot more difficult to dimension out and draw but the parts were so precise that they are totally interchangeable with the 100 year old hammers they will replace CJ

The taste of poor quality lingers long after the cheap price is forgotten.........

|

|

|

|

|

Joined: Jul 2006

Posts: 1,164 Likes: 11

Sidelock

|

Sidelock

Joined: Jul 2006

Posts: 1,164 Likes: 11 |

I was very impressed to see the application of wire cutting technology for the manufacture of replacement action components. In particular because we have seen your expertise in traditional methods. For your interest, Purdey is using wire cutting technology as part of their manufacturing process. This method of production offers excellent potential for reducing the cost of action and lock components made in small batches.

Roy Hebbes

|

|

|

|

|