Here's a few photos of test parts of 1018 mild steel that were polished to 320 in most cases.

Here are a couple photos of the loaded crucible and the system I have my students use when doing the quench. We have pretty much settled on a mix of 50/50 wood to bone charcoal though we have used other ratios in testing. Our temperature is around 1400-1450 in the furnace and probably around 1375-1400 at quench time.

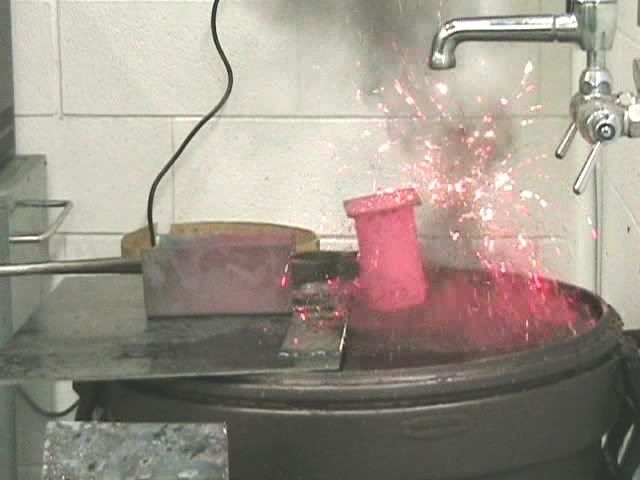

Lastly here is the video showing the whole operation. We were using the smaller furnace that Brownells sells, but we also have the larger one as well. I personally don't like the crucible that Brownells sells as it doesn't offer a really convenient way to dump the parts without exposing them to air (though others mileage could and probably does vary in this respect). The system that I use that is shown in the video involves minimal contact with the outside air as the crucible is only about 1/8" above the surface of the water when it is slid off the cover plate.

[img]

http://smg.photobucket.com/albums/v733/44-henry/?action=view¤t=ColorCaseVideo.flv[/img]