|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

4 members (CJF, Vol423, buckstix, 1 invisible),

449

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,479

Posts545,212

Members14,410

| |

Most Online1,335

Apr 27th, 2024

|

|

|

|

Joined: Feb 2003

Posts: 4,035 Likes: 47

Sidelock

|

OP

Sidelock

Joined: Feb 2003

Posts: 4,035 Likes: 47 |

Is that anything like dehydrated water?

Seriously... what, why, how.

Like the character in Dirty Harry, "I gots to know".

"The price of good shotgunnery is constant practice" - Fred Kimble

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Steel with the carbonation removed...

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Decarbonized steel is "Bessemer process homogenous wrought iron" I couldn't cut and paste so you'll need to scroll down to p. 46, but lots of good information here http://www.davistownmuseum.org/PDFs/GlossaryOfFerrousMetallurgyTerms.pdfFrom Fire-Arms Manufacture 1880 U.S. Department of Interior, Census Office (I suspect this came from PeteM) "The earliest use of decarbonized steel or gun-barrels is generally credited to the Remingtons, who made steel barrels for North & Savage, of Middletown, Connecticut, and for the Ames Manufacturing company, of Chicopee, Massachusetts, as early as 1846. It is also stated that some time about 1848 Thomas Warner, a the Whitneyville works, incurred so much loss in the skelp-welding of iron barrels that he voluntarily substituted steel drilled barrels in his contract, making them of decarbonized steel, which was believed by him to be a a novel expedient. The use of soft cast-steel was begun at Harper's Ferry about 1849. After 1873, all small-arms barrels turned out at the national armory at Springfield were made of decarbonized steel(a barrel of which will endure twice as heavy a charge as a wrought-iron barrel), Bessemer steel being used until 1878, and afterward Siemens-Martin steel."

Last edited by revdocdrew; 12/24/07 11:26 PM.

|

|

|

|

|

Joined: Dec 2001

Posts: 999

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 999 |

I've often wondered about this myself. Since basic steel (FeC) is an alloy of iron (Fe) and carbon (C), I would assume to remove the carbon would leave you with iron- right back where you started. I sure hope some of our talanted metalurgists (sp?) will chime in with an answer.

Cary

|

|

|

|

|

Joined: Jan 2002

Posts: 11,377 Likes: 105

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 11,377 Likes: 105 |

Jones, are you looking at a Remington 1889 by any chance? That's the term they used for the steel on quite a few of those, I believe.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

This is a repeat of several posts I made on this topic in couple of threads. Drew has already reposted the 1880 report. "Some Aspects of the Metallurgy and Production of European Armor" By Craig Johnson, first published in the Armored Proceedings Symposium Notes, 1999. The processes for turning iron ore into a workable material were known throughout Europe, Asia, and the Orient since antiquity. The product that was normally produced was wrought iron and later cast iron. Wrought iron never achieved a fully liquid state. A furnace held in the 1100°C to 1200°C (abt 2000°F-2200°F) range would allow the reduced iron particles of the ore to coalesce into a mass with the majority of the silicates liquefying and draining away as slag. What remained would be a spongy looking mass called a "bloom," the refining of which was accomplished by heating and hammering repeatedly to drive additional slag out and close any voids, resulting in a bar or plate of wrought iron. Iron produced in this way consists of large ferrite crystals and some slag inclusions and would have to be carburized to achieve a steely state. This carburization may have been accomplished in the furnace by lengthening the time the bloom is left in, tempreture increases or increases in the ratio of fuel to ore

.....

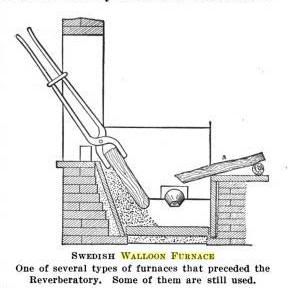

Cast iron needs the reverse process to be usable as a steel product. The material needs to be reduced in carbon content and this is usually accomplished by passing air through a stream of the liquefied iron onto a charcoal hearth, known as a finery, or "Walloon Furnace". There is some conjecture that such a process was being used in the pre Alpine valleys as early as the mid 13th century. By the 15th C. the Northern Italian production centers were casting iron cannon, which may indicate the technology was available in previous centuries to manipulate liquid iron. This also may have been the process used in Styria. The method for decarburisation by forging together cast and wrought iron and allowing carbon diffusion to take place resulting in a steel material is described by Biringuccio in Pirotechnia (1540) though this would be a difficult proces to control. Some have thought this maybe the "Brescisian Process" but this was probably a finery of some sort that was misunderstood by Biringuccio. The "Brescisian Process"may have been a source for the large amount of steel needed by the Milanese armorers. "Non-technical Chats on Iron and Steel: And Their Application to Modern Industry" La Verne Ward Spring http://books.google.com/books?id=7YJCAAAAIAAJ&pg=PA93&dq=Walloon+Furnace#PPA94,M1 The concept of the Walloon forge reached it's zenith in the Bessemer process. Bessemer Converter, the image is from Wikipedia  This was a later development. http://www.google.com/patents?id=Q4FUAAAAEBAJ&dq=BessemerPatent number: 16082 Issue date: Nov 1856 Pete

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Steel, by definition, is a mixture of iron & carbon with the optional addition of other elements to enhance it's characteristics. Thus "Decarbonised Steel" does not mean that in it's final condition it has "No" carbon. According to "Machinery's Handbook" in the Bessemer process air is blown through the molten iron burning out the carbon & other impurities, a batch of 15 tons containing about 3/4 ton of carbon. After this what is left is virtually a vat of molten wrought iron, to which is added the proper amount of carbon & manganese for the desired grade of steel. The "decarbonized" referes to the process of making the steel from cast "Pig Iron" which contains a large amount of free carbon. Note the 3/4 tons of carbon in 15 tons of cast iron amounts to 5% while Steel having 1¼% (only ¼ as much) is considered a very "High Carbon" steel, with "Mild Steels" generally falling into a range of .2% or less. Thus while 1500lbs of carbon were removed from that 15 ton batch of cast only about 60lbs would be added back to make a 1020 mild steel.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Feb 2003

Posts: 4,035 Likes: 47

Sidelock

|

OP

Sidelock

Joined: Feb 2003

Posts: 4,035 Likes: 47 |

Ah ha. I'm catching on. Sorry if I missed a previous discussion of this.

Not looking at a Remington, but it was ad copy of that era that caught my attention. Wondered how 'decarbonized steel' could be an effective sales pitch.

Appears to be jargon of the era. Decarbonized steel is simply steel it would appear. Refers to way in which the proper carbon content was achieved.

Thanks for the info and references... fun reading.

"The price of good shotgunnery is constant practice" - Fred Kimble

|

|

|

|

|

Joined: Dec 2001

Posts: 6,271 Likes: 202

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,271 Likes: 202 |

You see this steel on very early Parkers. Anyone have a photo ?

|

|

|

|

|

Joined: Jan 2002

Posts: 5,888 Likes: 107

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,888 Likes: 107 |

My question has always been is there any difference between the "decarbonized steel" barrels of the Grade 1 hammer doubles of E. Remington & Sons and Remington Arms Co. and the "Remington Steel" of the Model 1894 hammerless doubles of AR-/AER-Grade, FE Trap Gun, and Model 1900 K-/KE-Grades?

|

|

|

|

|