|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,481

Posts545,240

Members14,410

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

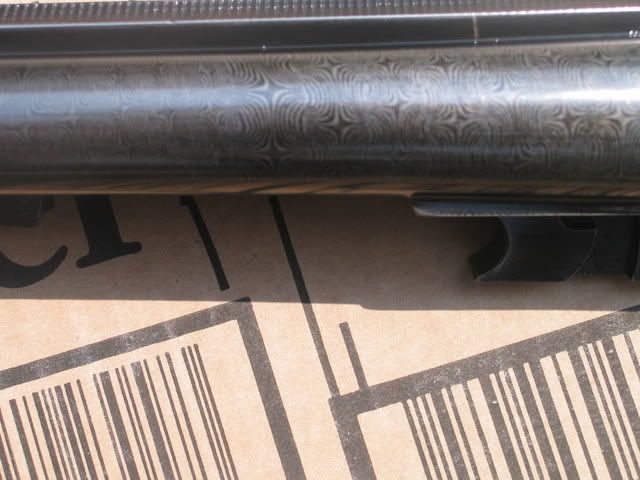

We're now up to album #35 and I seriously need professional help  http://www.picturetrail.com/gallery/view?p=999&gid=18015717 http://www.picturetrail.com/gallery/view?p=999&gid=18015717 I've posted the pics from Ross and Doug. I agree with Doug that we're probably looking at the end of individual 'strands' of wire which were braided, then twisted around the mandrel. This courtesy of Tom Flanigan; a Parker GH Three Iron D2 with an apparent weld line  So gentlemen: please check your damascus barrels for odd patterns, flaws, etc., take ultra-close-up pics like those posted, and send by jpg attachment to revdoc2@cox.net and thanks! BTW: what would you give for a time machine that enabled us to visit E. Heuse-Lemoine in Nessonvaux (and speak French) and talk damascus barrel production with one of the workmen?! I don't want to give away too much, but Pete M may have found one!! More to follow.

Last edited by revdocdrew; 10/08/07 09:14 AM.

|

|

|

|

|

Joined: Aug 2007

Posts: 10,785 Likes: 185

Sidelock

|

Sidelock

Joined: Aug 2007

Posts: 10,785 Likes: 185 |

revdocdrew:

According to W.W. Greener, there is an attempt in making the barrel out of rods but to make the barrel to appear to be made from 1 rod viz.; "By tracing the twist, a confusion will be found to exist for about an eighth of an inch, every six or seven inches; and from this appearance you may conclude that, for a barrel so joined, the welder had not the best price."

This may account for some of the imperfections or perturbations.

Kind Regards,

Raimey

rse

rse

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Thanks Raimey-I'll add that to the intro page (but am not entirely sure what manner of 'English' that is  )

|

|

|

|

|

Joined: Aug 2007

Posts: 10,785 Likes: 185

Sidelock

|

Sidelock

Joined: Aug 2007

Posts: 10,785 Likes: 185 |

revdocdrew:

If need be, I will attempt to take a pic of the pages it is contained within and email it to you.

Kind Regards,

Raimey

rse

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Found another one guys. I think this is Leighton Stallones Remington 1889 'Fine Twist' hammer gun. Similar anomaly in the middle of the right barrel with a possible weld just to the right of it

Last edited by revdocdrew; 10/08/07 10:33 PM.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Leighton sent two close up pics The first with the flaw and a weld line  The second with several 'bullseyes' near the receiver, that he believes to be part of the pattern rather than related to the re-finish.

Last edited by revdocdrew; 10/09/07 08:24 PM.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Courtesy of David Trevallion, 12b c. 1867 MacNaughton of Edinburgh sleeved from damascus to steel...back to damascus; with silver between all 4 joints. By John Foster and Graham Bull, England. Obvious crolle pattern barrels, but the rib appears to be laminated steel?   After the sleeving it was submitted for Proof at the London Proof-House; passed 70mm x 950 bar.

Last edited by revdocdrew; 10/11/07 09:42 PM.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Thanks Pete.

I found this in the 1907 Greener's The Gun on p. 237

“The numerous twistings and weldings of gun-iron rods and ribands are fully detailed…and it must have occurred to the reader that the Damascus barrel is one mass of welds from breech to muzzle. This is so. Unfortunately a certain amount of burnt metal, or scale, is imbedded within some of the welds, and in the finished barrel this fragment of scale forms a “grey”…which will not colour in harmony with the other part of the barrel, but is made more apparent by the finishing processes of polishing and browning. These “greys” may appear some time after the gun has been in use, the hard metal composing the barrel being eaten into by rust…They are developed in the inside by the chemical action of powder gases, and are almost ineradicable. The harder the Damascus the greater the liability to “greys”…

I'm not sure the bulleyes on Leighton's Remington are "greys"

Last edited by revdocdrew; 10/20/07 09:02 AM.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

Drew,

Interesting observation by Greener. I have had barrels redone. In the process they had to be redone several times because some areas, or sections did not react to the chemicals in the same way resulting in an "uneven" look. I remember reading the same thing here by several different posters. Perhaps Greener is on to the reason.

Pete

|

|

|

|

|

Joined: Dec 2001

Posts: 3,574 Likes: 87

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,574 Likes: 87 |

16ga 32" barrels on a W. Crawford of Birmingham. The area is smooth as glass. [url="http://www.hunt101.com/?p=523295&c=500&z=1"]  [/url] [url="http://www.hunt101.com/?p=523296&c=500&z=1"]  [/url]

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Thanks Mike! We'll get that added to the album. Drew

|

|

|

|

|

Joined: Jan 2002

Posts: 461

Member

|

Member

Joined: Jan 2002

Posts: 461 |

here is a Remington model 1894 i refinished. it looks little odd. Before   And after   Casey

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

VERY INTERESTING Casey-there is clearly a transition (and weld line) from 'Oxford 2 S.J.' Two Iron Crolle at the breach to a 'Boston 2 S.J.' pattern!! Is it an 'A' grade? Thanks and I've never seen two damascus patterns in the same set of barrels, and with the transition at about the same place in both tubes!

|

|

|

|

|

Joined: Sep 2003

Posts: 257

Sidelock

|

Sidelock

Joined: Sep 2003

Posts: 257 |

Is that a cut line on the rib or just a scratch?

Mark

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Casey that's not unusual for the pattern to change ahead of the chamber area...I suspect it had something to do with the barrel being built to handle pressure.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Mark Harrel I hope that bad spot is close to the muzzle.

|

|

|

|

|

Joined: Dec 2001

Posts: 3,574 Likes: 87

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,574 Likes: 87 |

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

jOe: I believe those are two different damascus tubes welded together. The individual 'leaves' in the scrolls of the Oxford pattern near the breech are much thicker than the leaves in the Boston pattern toward the muzzle.

Please post some pics of other examples!

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

The pattern looks the same to me just "tighter". I think it's just an example of a "better barrel".

Check out the pics of the Blisset....the Damascus pattern tightend up on it. I don't own the Blisset anymore so I can't post pics of what I'm talking about. The Damascus pattern matched to a tee on both barrels.

What I see in the picture at the top of this page...is a barrel made by a less experienced barrel maker. That "anomalie" no doubt left the shop like that.

The best barrel makers made the best barrels and they went on the higher grade guns.

|

|

|

|

|

Joined: Jan 2002

Posts: 461

Member

|

Member

Joined: Jan 2002

Posts: 461 |

Rev

I think it is "A"grade, and the model is 1900 not 1894

Mark

The cut line is where the rib join the extension that is the part of barrels or "monoblock".

I am not sure how Remington made them.I will check it out.

Homeless

I have a Blisset that is on my list for refinish. when it done I will post some pictures.

Casey

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Thanks Casey-that would make it a KD. Drew

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

I believe that virtually all damascus bbls were made of two tubes joined together. The breech section was formed thicker than the rest of the bbl. Many makers tried their best to make this as invisable as possible, but obviously all didn't. I seem to recall Greener stating this "Breech Tube" to be about 9" long but suspect that varied according to exact desired finish contour. The two sections were then sort of "Butt Welded" together.

That joint in the rib will be found on most guns with either a dolls head or top bolt. In these cases a short section of the top rib with the extension is brazed in along with the joining & lug. The remainder of the rib, under-rib etc will then be soft soldered. On guns without a rib extension the entire rib is usually one piece & softsoldered in after the breeches are brazed.

Off hand I can think of no American built gun which used a monoblock, but if someone has knowledge of one I can stand corrected. A few had chopper lumps, but most were conventional or dovetail lump joined.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Aug 2007

Posts: 10,785 Likes: 185

Sidelock

|

Sidelock

Joined: Aug 2007

Posts: 10,785 Likes: 185 |

True, according to Greener: "It is usual to make a gun-barrel in two parts. The breech is made of thicker strips than the muzzle."

Regarding lumps, Greener preferred "a solid steel lump fitting between the barrels, extending upwards to the top rib;" His next choice was a lump forged on the right barrel because it was used more. Greener considered the lump patented by Mr. Parsons of Birmingham(chopper lump) to have a weakness due to the amount of surface area that had to be completely brazed.

Kind Regards,

Raimey

rse

|

|

|

|

|

Joined: Oct 2005

Posts: 3

Junior Member

|

Junior Member

Joined: Oct 2005

Posts: 3 |

Pete, I suspect that the uneven look you refer to may be the result of an error(s)in the etching process (most likely) or due to carding issues. If the uneven look was due to "greys", then I believe that redoing the barrels would not resolve this issue. I will be finishing up a set of Parker GH barrels that very definitely exhibit the "greys" effect. On a section of one of the tubes, the "greys" start abruptly and end abruptly along weld lines. It is a very interesting effect and not all that common, in my experience.

|

|

|

|

|