|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,467

Posts545,110

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

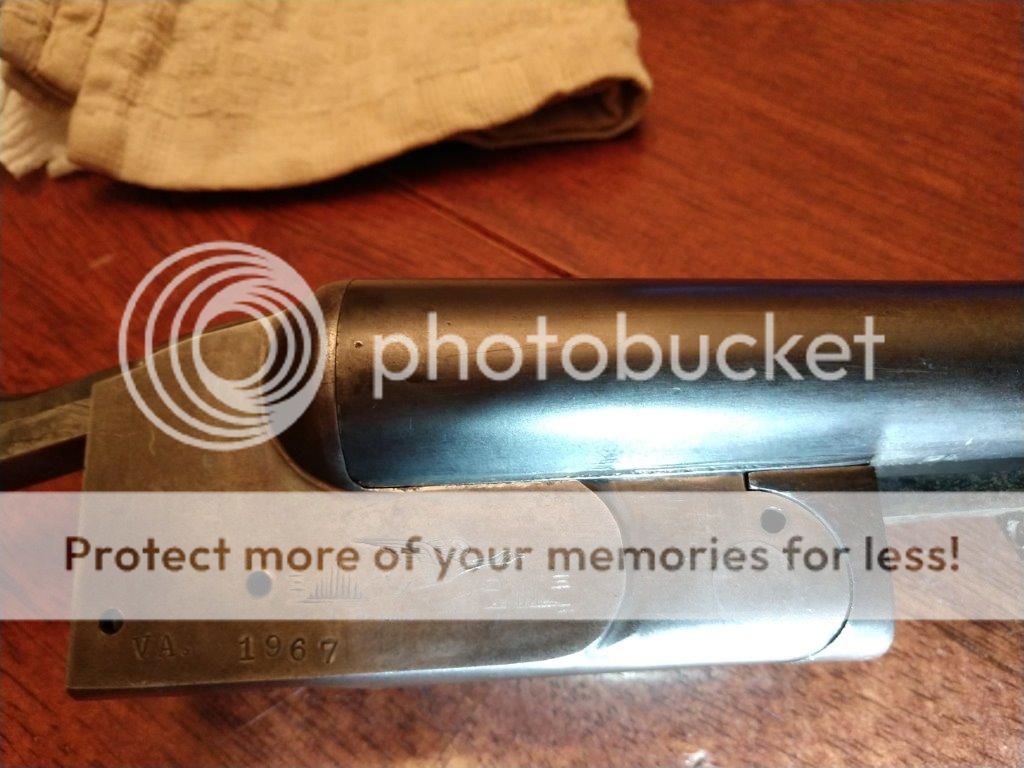

I am working on a couple low value projects to learn on. I have a Lefever Nitro special receiver and a barrel that I want to fit up. I would appreciate some help on next steps. The barrel has little to no sideways movement but when closed the barrels do not want to lay flat on the water table. The chamber end of the barrel does not touch the breach face anywhere but is very close. See following pics.     On the next picture my intuition would be to flatten out the area @ B with the rest of the barrel flat but not sure if it is B or the shaded part of the hook that is keeping it from laying all the way down  Here is what the inside or the receiver channel looks like.  Feel free to give your wealth of experience and knowledge. I appreciate the help here. If there are some written references for this or video links I would appreciate the input. Many Thanks Travis

Last edited by Travis S; 02/14/19 05:51 AM.

|

|

|

|

|

Joined: Sep 2018

Posts: 11

Boxlock

|

Boxlock

Joined: Sep 2018

Posts: 11 |

It looks to me like the barrel is touching the breech face at the lower right in the next to last photo. Blacken the breech end of the barrels and the surface that meets the water table.

I've used inletting black, candle black and medium and fine grit stones to very carefully stone the high spots. I'm certainly not an expert but I've built a number of nice flintlocks and restocked and rehabbed a few nice old SxSs using classic gunmaker techniques.

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Travis, a properly fitted barrel set flat shouldn't touch the action flat, except just a wee bit at the front, closer to the hinge pin. Done right, light should show at the rear portion of the barrel flat/action flat relationship. This allows for a "settling in" which definitely will occur, even with the best of barrel fitting.

Striving for as much contact between the barrel breech faces and the standing breech as possible s critical. Few gunsmiths can do this properly. I have done the job, myself, and can say that it is extremely tedious work. It doesn't always work out, and even a good fitter will have too start over sometimes to get it just right. Many claim to be barrel fitters but few can do it really right. I have had some very bad experiences with nationally known and recommended double gunsmiths with barrel fitting. One gun came back with about 35% contact at the breech on one barrel and NONE on the other, daylight showing strongly from top to bottom. And this was from a 'smith whose name has been thrown around on here as being a master 'smith, for many years. Not.

Good luck with it. You can't go too slowly and you can't be too careful. You re very wise to practice this craft on inexpensive guns.

SRH

Last edited by Stan; 02/13/19 11:04 PM.

May God bless America and those who defend her.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

What Is the maximum gap or recommended gap between the table and barrel flat closest to the breach face?

would this relation between the barrel flat and table be best adjusted by removing hook metal or barrel flat metal or is there some standard evaluation method to make that determination?

I apologize for all the questions I googled and googled first but to no avail.

Thanks again

|

|

|

|

|

Joined: Dec 2001

Posts: 6,993 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,993 Likes: 402 |

Travis,

The gap between the barrel flats and water table should be about .010", a small amount more or less is not a big deal. Often times fitting barrels from one gun to another is a compromise at best. Sometimes a perfect fit is possible, other times it is not. Much hand work originally went in to these old guns so some variation is to be expected.

From where you are at I would approach it the following way. Smoke the barrel lug, hook and breech face of the barrels to see where you have contact. I agree with Roger that it looks like the lower corner of the breech face is in contact with the receiver. If that is correct, then material will need to be removed from the hook allowing the barrels to seat deeper in to the action. If you want to post pictures of your barrels after smoking them in I can offer more specific advice.

Steve

|

|

|

|

|

Joined: Jan 2002

Posts: 1,563 Likes: 70

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 1,563 Likes: 70 |

|

|

|

|

|

Joined: Feb 2002

Posts: 1,850 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,850 Likes: 150 |

Don't work over anything especially the hook till you have established where exactly things are interfering.

Smoke the bbl as others have said and carefully place it back on the frame and close it. Back it off and examine.

One thing I do see that might be a problem is that the front edge of the bbl flats is hitting the frame flat (water table) before the bbl can sit all the way down.

The bbl can't pivot & wrap it's way around the bbl flat. It should come down on it.

That faint line straight accross the bbl flat even with the hook is probably the impression of the front edge of the frame flat(s).

It may or may not be interfering,,that's what smoking and checking the fit is all about. But it's something to look for.

Relieving the hook contour to fix that will allow the bbl to sit higher for sure. But at the expense of a sloppy hinge joint where the hinge pin is round and the hook is then oval shaped.

Go slow, look for the tiniest interference betw parts. They don't always jump out at you as large bright spots rubbed off of the smoked part.

Don't forget to check the bbl rib extension for interference in the frame cut too.

Take the extractor out of the bbls while doing the initial bbl fit. It looks like you have already,,,You want just the bbl and the frame to be fitted.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

Where can I get one of those real sooty smoke rolls that I see on the midway videos?

I have a Kerosene lamp already but the smoke thingy looks a lot more sooty

I have looked but cannot find one or how to make one.

Thanks

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

I use a tiki torch canister as a source of soot.

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Want me to send you a few sticks of fat lighter? I'll be glad to if you will p.m. me your address, no charge. It smokes just like the kerosene soaked stick in the video.

I use a little alcohol lamp I bought on eBay, filled with kerosene.

SRH

Last edited by Stan; 02/14/19 06:10 PM.

May God bless America and those who defend her.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,463 Likes: 207

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,463 Likes: 207 |

Travis,

You can adjust the kerosene to smoke.

Mike

|

|

|

|

|

Joined: May 2008

Posts: 8,158 Likes: 114

Sidelock

|

Sidelock

Joined: May 2008

Posts: 8,158 Likes: 114 |

I still have the carbide (acetylene based) lamp from Camp Matthews CA- where we qualified with the M-1's- and later, the M-14's-- Use a acetylene torch without the oxygen and you'll get all the soot you need. RWTF

"The field is the touchstone of the man"..

|

|

|

|

|

Joined: Feb 2002

Posts: 1,850 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,850 Likes: 150 |

I just use a Zippo most of the time. Gets kinda hot after a long session but at least the room doesn't fill up with soot.

The other thing that works pretty well is inletting black,,but you have to put it on VERY sparingly. You don't want any build up of the marker on the surfaces.

For that a toothbrush works well and start out with just a dot of the black onto the bristles. I charge and if needed recharge the brush by swiping it into the inside of the cap on the little bottle.

There's more than enough there to do the job. Scrub it onto the metal surfaces you want to blacken and it'll just barely darken them,,that's good enough to get a read.

No candles, no soot lamps, no Zippos

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

Be sure to keep the barrel flats equal distance above the water table. If you don't the center of one chamber will be higher than the other.

|

|

|

|

|

Joined: Jan 2002

Posts: 7,703 Likes: 103

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 7,703 Likes: 103 |

Prussian Blue just because it is so easy to clean up. NOT...Geo

|

|

|

|

|

Joined: Jul 2012

Posts: 4,463 Likes: 207

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,463 Likes: 207 |

I watched my German friend Gerold Pheffer fit several barrel sets to guns( two of which were mine). He fit the barrels to the receiver without the hinge pin being installed. After he was satisfied with the fit, then he marked and cut the "hook" in the barrels. He polished with a fine cut file, loaded with chalk and oiled; that is removing almost no metal in the final fit. He "filed like a machine", at times working thousandths of an inch from thousands of dollars worth of engraving, without putting a scratch on it. Amazing. It may help if you remove the hinge pin, fit the barrels, then replace the pin.

Mike

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

I appreciate all the input. I am making progress but am intentionally taking it slow. My tendency is bull in china shop but I am working on my finesse game:). I will post some pics of process and progress.

BTW why hasn't anyone mentioned a black sharpie marker?

|

|

|

|

|

Joined: Jan 2002

Posts: 674

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 674 |

https://www.ebay.com/itm/Alcohol-Lamp-Burner-Glass-Spirit-Lamp-with-3-16-Adjustable-Wick-1-Extra-Wick/222858253306?hash=item33e36313fa:g:FoEAAOxylk1RehxY:rk:6:pf:0

i use kerosene in an "alcohol lamp." run a tiny flame when not smoking and makes little smoke and not hot at all, even with a large flame.

skunk out

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

I have been working on this intermittently since I originally posted. This barrel is from and earlier Nitro special but my receiver is a later receiver. It just so happens there is an earlier shotgun in a local gun shop that I looked at today and observed some differences. The earlier gun has a little recess in the water table at the lever trip hole and the area "B" fits down in that recess and the recess allows the raised area "B" to drop down below the water table allowing the barrel flats to sit down on the water table. The later receiver I have does not have this recess so I flushed the raised area at "B" down equal to the barrel flats. I have been using a sharpie marker up to this point but I feel I am getting down to the critical last adjustments so please feel to chime in. This is what I am working with prior to blacking with the sharpie marker.  I can get a .005 feeler gauge in at both sides close to the breach but it is tight closer to the pin. I cannot see any light now between chamber face and breach face.       This is what it looks like after blacking and setting the barrel 5-6 times.    Thoughts? Many thanks Travis

Last edited by Travis S; 02/16/19 08:51 AM.

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

You are really close. put the extractor back in as it may or may not interfere. Use some 4 or 600 grit paper with a metal backer to lightly polish the high spots on the breach end and the end of the locking extension. How much contact do you have on the hook? you should get the top lever back in to see how it mates to the locking extension. get all that done and the fore end iron will probably need fitting. Good work and good luck.

|

|

|

|

|

Joined: Feb 2008

Posts: 11,343 Likes: 389

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,343 Likes: 389 |

You were advised to lightly polish high spots on the breech end. Lightly means just that as I learned on my first attempt at fitting an orphan set of Armor Steel L.C. Smith barrels to a OO grade with a blown barrel. Working slow and careful, I got the gun to close perfectly with proper clearance under the barrel flats, good bolting, top lever right, etc. My total cost for the blown gun and orphan barrels was about $100.00, and I was happy to make a cheap shooter. All was great until I found that I took a bit too much off the rim depth and some (most) ammunition with slightly thicker rims wouldn't permit the gun to close properly. I had made the mistake of stoning a few thousandths too much off of the breech end of the barrels instead of stoning the hook. Learn from my rookie mistake that you often can't put metal back once removed.

Fortunately, I was able to borrow a reamer to cut the rim depth a bit deeper on both barrels. I've used kerosene soot lamps, Dykem layout blue, Jarrows black, etc for spotting. And RWTF is right about a small straight acetylene flame making lots of soot. But one very cheap and readily available item for your arsenal is to hit up your wife for an old tube of lipstick. A thin coat on one surface will easily transfer to the opposing contact surface, and show high spots very well. Some acetone on a rag will clean it right off. I'm not so keen on this for inletting wood although some use it. I got this idea from one of the Brownell's Gunsmith Kinks books, which are a great source of tips and ideas.

A true sign of mental illness is any gun owner who would vote for an Anti-Gunner like Joe Biden.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

I forgot I had an old kerosene lamp so I put that to good use. Here is the progress. I am assuming I want almost 100% contact?

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

Coming along great. You do need to put the extractor in to see what it is going to do.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

OK 1st of all I do not know how long it takes master barrel fitter to do this but I have about 6 hours in it up to this point This is the latest without the extractor.  Just for conversation sake. Assuming the extractor has no impact (I am sure it will) how much more of the chamber face am I expected to have shinning to be considered done? Thanks for all the input. The barrel gauges at .730 both sides and I cut the barrel down to 27" from 30". Besides wanting that length I figured it would also give me a chance at barrel soldering and eventually slow rust bluing. Also I am sure the shell face rim will have to be re-cut. I am also going to carve a beaver tail fore end and a new stock. This is one of two projects the other being a real nice and tight Fulton special 16 gauge that I am doing to have a go at working through many of the steps of restoration. I have a couple 20 gauge LC smiths and that will get the benefit (hopefully) of the effort. This shot gun is going to be my tight woods close to home flooded timber woody duck gun. Thanks again. Travis

Last edited by Travis S; 02/17/19 01:55 PM.

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

That is pretty much there. how much contact does your smoke show on the hook? I doubt you removed enough metal to effect the rim cuts. A beavertail fore end puts a lot of extra force on the fore end hanger, don't be surprised if it eventually pops loose.

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Travis, that is excellent fitting. Some so-called "master" double gunsmiths can't get one with that much contact. If it looks that good with the extractor in, I'd leave it alone.

How does the barrel flat to action flat relationship look?

SRH

May God bless America and those who defend her.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

First of all if you ever hear of me wanting to do this again please send me a self addressed envelope and I will send you a plane ticket to come down here so you can kick me in the nads. Holy moly what a chore. I spent 5 1/2 more hours on it after my last update. It really ended up being a test of will. The barrels were still riding high so I kept at it and had to work on about 7 areas simultaneously to end up with what I hope is a good fit. There is at least 85% breach face contact and the barrel flats are almost 50 contact with the tightest being over the pin. I polished the barrel face with 320 grit. Any reason to go finer? The extractor fitted just fine and operates properly but I did note that one of my shot shell brands did fit tight but I tried about 5 others and they were fine. I will forgo messing with rim depth cutting for now. I have not checked hook/lever contact yet but it feels pretty smooth with some good travel. Many thanks for the input and direction. Pics of what I hope is the final product. At the risk of jumping off a bridge, if you see something that needs attention I guess go ahead and tell me  Thanks again

Last edited by Travis S; 02/19/19 01:33 AM.

|

|

|

|

|

Joined: Apr 2005

Posts: 1,688 Likes: 31

Sidelock

|

Sidelock

Joined: Apr 2005

Posts: 1,688 Likes: 31 |

I hope you are not leaving the extractor looking like that?

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

If you don't have at least 50% contact on the hook it may shoot loose again. But you have gotten past the biggest hurdle. The next one will take you a lot less time and the one after that will be less. Good work!

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

For Salopian I did clean up the extractor.

Mark II what is the next step after lever surface adjustment.

Many thanks

Travis

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

If it locks up tight and the fore end looks like it fits take it out and shoot a couple boxes of shells through it and see what happens. If there is any movement in the lock it needs to be tightened up or everything will shake loose pretty soon.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

Back to work on the ole lefever

I have the barrel and top lever fit (I think)and wanted to take it out for a few shots before pr0ceeding with other work.

I am seeing something that concerns me.

When I have the barrel on the receiver and minus the forearm metal, with good thumb pressure on the front pushing it into the barrel I see no light and cannot get a .0015 gauge to even get started anywhere around the barrel/breach interface. This the same whether I have to top lever engage or not.

Ok now when I put the forearm metal on. the metal snaps down pretty tight and I can tell it tensions the whole set up and although not bad does tighten up the opening/closing of the assembly. The thing that concerns me is that this opens up a gap on the left barrel face and I can now barely slide a .003 gauge in the gap as well as see light evenly around the whole barrel face surface. this is only on the left barrel.

When I take the forearm metal off I cannot feel any lateral movement between the barrel and receiver when closed and just a bit when opened.

What say ye?

The gun is looking good though so I have that going for me.

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

The fore end iron or hanger needs a minor tweek. Either the back of the iron slot or the back of the hanger. The pressure creating a gap may indicate the hook cut being a bit deep. Smoke everything up , put the foe end iron on and see what is going on. Fit the FE iron shoot it , then re-smoke and see if anything moved.

|

|

|

|

|

Joined: Feb 2002

Posts: 1,850 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,850 Likes: 150 |

The forend exerts forward pressure on the bbls,,backward force on the frame when it's snapped/locked into position.

It is pushing the bbls away from the frame.

If there is space betw the bbl face and the frame anywhere with the forend in place, then the bbl's are off face at that spot. even though they can exhibit a very tight fit in the action and on the hinge pin. They are just short of reaching the face of the frame.

IF there is space betw the bbl flats and the action flat (water table) yet, the bbl can still rotate downward a little and it may be enough to close the .003 gap at the one point.

You might not have quite enough room to close it up completely, but at least get rid of some of it. You can always put a bit more clearance down there by trimming the bbl flats. It's only a few .000 but watch what you are doing as the bbls are made to only set down so far.

Remember the firing pins must hit the center of the chambers!

Go too far chasing a tight breech fit and then wonder if the sadly off center firing pin hits will work OK.

Spotting and fitting in the forend any more against the forend bbl hanger will jut make the condition worse as it will then allow the bbls to not only be off face,,but also loose on the hinge pin.

Thats where they start to shuck back and forth and the quick fix is to peen the forend iron on the bottom side to stretch it. That puts it tight once again betw the hanger and the nose of the frame.

It still won't cure any gap/off face problem at the breech.

You either have to rotate the bbls a little more in fitting to make up the gap as above or,

you have to move the bbl back from the hinge pin by enlarging the hook (shim, welding, inlay) or a new oversize hinge pin to move the bbl back those few .000 to allow it to reach the breech face.

Then the refitting once again of the breech face of the bbls to the frame face and probably the forend will need to be refit as the bbl hanger has now moved backward with the bbl assembly and will extra tight when putting on the forend. That's a good problem to have.

It's very difficult to read and feel with hand pressure only wether the action and bbls are really tight. Nothing like a heavy spring closing the action or the forend snapped and locked into place.

One pretty good way to tell if it's tight by using you hands and hand pressure to hold it closed and checking is put the bbls in the vise upside down with the action on it. Having the butt stock attached is even better as it gives you some leverage.

With the unit upside down and held by the bbls up close to the breech so you can tighten them securely,,pull down on the action/stock assembly as if to lock it closed.

You have a lot of leverage there and can hold it closed with one hand while checking with the other hand for the slightest movement around the bbl and frame areas.

Wrap your hand right round the breech joint areas and try side to side movements with the action with it pulled tightly closed.

Your hand will pick up even the slightest movement of the frame/bbl joint at any point.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

OP

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

Thanks for the feedback

reporting progress

Ok I am doing this project for a learning experience. Up to this point I probably have a $2,000.00 Lefever nitro special 12 gauge, considering the time I have into it so far. Did the factories spend this much time fitting up these guns or am I going to have a North Florida Best Grade Lefever when done?

I took the forearm metal off and took the hanger catch and spring off. I put the metal back on and noticed the stem of the metal needed to move over just a bit to get the hole over the hanger. The direction it needed to move would be toward the left barrel barrel which is the barrel showing a smidgeon of light when the FA metal is attached.

Zip......Light bulb turns on over the head.

I did the following:

Smoked the FA metal in the round and reattached and worked the action and sure enough there is good contact on the side of the left barrel and no contact on the side of the right.

I polished inside the left side of the round keeping pressure on the left and nothing on the right until metal drops down with even touch between the sides of the FA metal slot and the sides of the barrel hanger.

I worked the barrel flats down a fart skin.

Results:

Action definitely opens and closes smoother. With spring loaded and forearm metal reattached, no light on either side even with top lever not engaged.

This gun will not get shot much but I will get it re-assembled and shoot a box of shells and see what happens and report back.

Thanks again

|

|

|

|

|