|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,463

Posts545,037

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

I was wondering if anyone has used a hot plate/cooker ring for the above. I use the salts from Dyson and up to now, have been heating it in a stainless beaker over a small gas camping stove. I find it can be time consuming as it's easy to get the molten salts too hot even at the lowest flame setting so have been taking the beaker off to let it cool then during the re heat, dipping the parts in and watching the colour change until they're the nice royal blue I wanted. I've seen a few ways to do the job from kilns to burying the parts in brass filings on a hot plate etc but thought a simple hot plate or single ring cooker/hob could be the way to go for heating the beaker of salts to the right temperature then relying on the thermostat to hold it there. I'm sure there will be some trial and error involved getting the temp correct and constant but I've seen a 1500w electric mini hob for £12 ($15 or 4 beers  ) so thought I'd ask if it's worth going down that road, if so, and the salts are held at the correct temp', could all the parts, large and small, be dropped in at once and pulled out when the desired colour is reached ? Any ideas or input gladly received. Thanks, Nick.

Rust never sleeps !

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

Purchase a high temperature cooking thermometer this takes the guesswork out of nitre bluing. Take a look on ebay for an all stainless steel type, they are usually not much money.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

You need a heat source that will do 600 degrees F. For smaller parts a Lee lead pot works well. YMMV

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi Damascus, I've got thermometers that go high enough, it's finding a heat source that's more controllable than my ye olde camping stove that I'm looking in to.

It's mainly to save time (if possible) while still getting every part the same shade of blue. It's one of the little jobs that I really enjoy but can easily turn into half a day if I don't keep my eye on the ball and go too hot.

Thank you for the suggestion though.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi Mark, thanks for the input too. I looked at various lab hot plates and lead/jewellery pots but the prices were a bit to high to justify the outlay. I will probably buy the cheap hot plate as it can still be used for boiling off small parts (and making a cuppa) even if it proves to be useless for the nitre pot.

Rust never sleeps !

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

Aaah! grass hopper!! Constant temperature source is a very difficult ask. I feel sure that you will have to keep your eye on the ball even with a single ring electric cooker, because the hysteresis of the thermostat type used in those cookers has a rather wide on off spread. A way to smooth the temperature swings is to use a metal container with a layer of sand between the heat source and the bluing salt container, start with about an inch of sand.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

I see, does the sand act as a heatsink and steady the temperature ? It's got to be worth a try then.

I'd looked on a chemistry students forum and one guy gave the part numbers for a pretty accurate thermostatic control and a temp sensor with digital display which were quite cheap. He'd modified a single ring plate element cooker and reckoned he could make it almost as accurate as the laboratory version the original poster needed but couldn't afford. Feels like a project egg has just hatched.

Last edited by El Garro; 05/04/17 06:40 PM.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

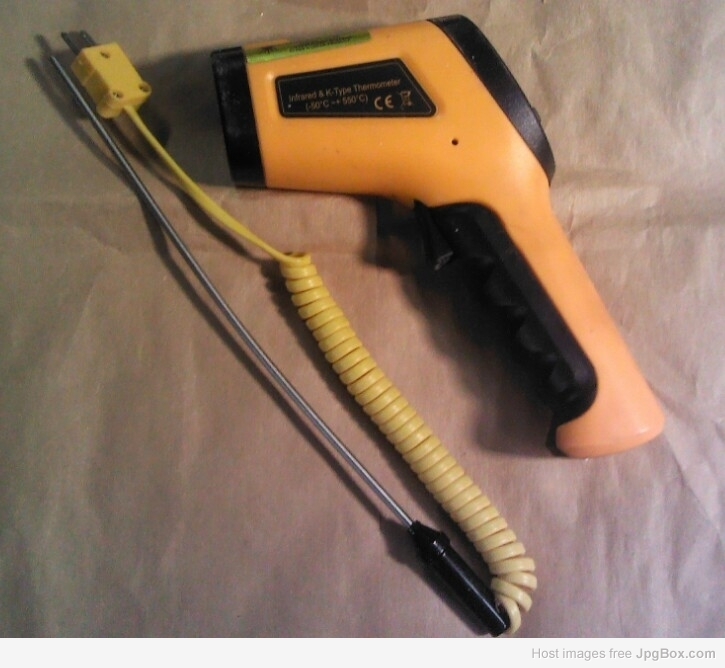

Here's an off-the-wall method that I intend to use. I installed a digital controller on the small electric kiln I use for case coloring. It should hold the pot at the correct temp with no problem, and it's top loaded. It'll also be easy to shoot the temp with my infrared thermometer.

Regards

Ken

Last edited by Ken61; 05/04/17 05:52 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi Ken, thanks for the suggestion. At risk of sounding like a miser, I'd not planned to spend much cash . It's got me thinking though. If the heat could be regulated accurately enough and then use a sand 'jacket' around the beaker on the hot plate it should act like a kiln.

The question now is. If, the molten salts could constantly be held at exactly the right temperature, would the workpiece stay the same colour whether it's dipped in just long enough, or, left in for a minute or two ?

Would the oxide layer stay the same colour or would it's thickness or density alter and change the colour or go dull with scale?

I wanted to see if it was possible to wire the whole batch of parts together and do them all in one go.

If the difference in time, albeit seconds, that different sized pieces will reach the temperature of the salts around them wasn't an issue, it could be a time saver.

Last edited by El Garro; 05/04/17 06:38 PM.

Rust never sleeps !

|

|

|

|

|

Joined: Feb 2011

Posts: 1,405

Sidelock

|

Sidelock

Joined: Feb 2011

Posts: 1,405 |

Nitre blue will also give a jet black color but the target temp for that is 830 degrees. Talk about it being tough to get them that hot. I normally can get my salts up to 725-750 on a gas stove with an aluminum foil heat shield to retain the heat in more. And i get decent color for trigger guards and triggers at those temps.

I have looked into furnice pots a few times, but they are a lot of money.

Last edited by B. Dudley; 05/04/17 08:45 PM.

B.Dudley

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

I've got more money in my digital controller than I do in my kiln. My small Duncan kiln was only $30 at auction, but I had to spend around $100 on the controller. Wiring it was fairly easy.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jan 2002

Posts: 1,563 Likes: 70

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 1,563 Likes: 70 |

Hot plate will work. New ones are junk and kick in and out and don't hold temp. The old ones with the exposed wire coil work good but I like the controllability of gas.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

El Garro using sand to level out the rise and fall of the applied heat is not a new idea though I do wish I could say I thought of it, but I would be a couple of hundred years too late. It works so well because sand is a poor conductor of heat so fluctuations are rendered much slower because of the sands poor heat conductivity.

I would like to pass on the origins of using this method of bluing steel only using heat and no other chemicals.

If you look at a very high quality time piece one of the things you will notice is that the screw heads the clock hands are a striking colour of blue, all produced by using heat alone. Now I am sure that at some time or other you have heated a Steel screw in a flame to turn it blue and that colour is fine, now the clockmakers of times past realised that if you polish the screw heads and clock hands to a high polish finish. Then by heating them up very slowly the oxide layer on the metal thickens and the finer the blue colour becomes, so to keep things stable they used sand as a heat buffer. And that is how the screws and hands on old quality time pieces have that wonderful deep translucent blue colour.

Of interest to some folks and may be not others.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Here's a question. If going up to 830 degrees, as Brian pointed out, (which is easily done with a kiln) which is the better medium?

Salts, or Saltpeter, such as stump killer, or is it better to use lead?

Regards

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Thanks again for the input Gents, I've been able to get the salts up to a high enough temp to black a few pins but not managed to get any larger parts past the 'iridium' looking stage, I'd assume that's down to the small heat source , hopefully I can improve things there. A small kiln or melting pot is starting to sound more appealing, cost may be prohibitive for one large enough to do a long trigger guard though. That's something I need to look into. Having ordered the hot plate in a moment of madness  (£10-last couple in stock) I will have a crack at fitting an improved thermostatic switch , I believe the temp sensor is fixed to the plate so should be an improvement from the start. I can get thermocouples and all kinds of temp control gear from a guy I know who's an instrument man in the chemical industry (he's helped me out with my caustic tanks already) so should be able to cobble something together and do some trials. If it's fails miserably , a kiln or similar is the next step. Thank you for all your ideas and suggestions, it's extremely helpful and much appreciated. I will get busy when it all arrives write up the results.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi ken, interesting thought about lead vs salts.

Although there may be some nasty fumes from the lead (easily solved with ventilation) could there be a benefit with it in the case of an accidental spill or splash. I believe that salts at that temp can make most organic matter, i.e. wood, paper, cloth burn at an alarming rate.

I know we can avoid this happening by taking care while working but it may add a point in favour of lead.

Last edited by El Garro; 05/06/17 07:16 AM.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Rust never sleeps !

|

|

|

|

|

Joined: Dec 2008

Posts: 277 Likes: 4

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 277 Likes: 4 |

I tried the "commercial grade

...ie..expensive type for nitre bluing..wont get hot enough. But it's only 110v, next will be a 220v set up.

Right now I'm using a led melting pot with a pid temp controller

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi Mike, I read an article about a lyman pot with a pid controller. What a clever bit of kit they are. Did it take many cooling/heating cycles to adjust itself ?

My hot plate hasn't arrived yet but I'm tempted to look for a lead melting pot as I was surprised by the reasonable prices of some models.

Rust never sleeps !

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

If you are doing larger parts, a propane burner and a metal box about the size of a .50 BMG ammo can, and thermometer works well.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

You can "Kill two birds with one stone" by buying an infrared thermometer that has the feature of allowing a K type thermocouple to be attached. You can go up to fairly high temps that way. I got mine off EBay.  Regards Ken

Last edited by Ken61; 05/08/17 04:35 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

My nitre bluing set-up. Reuseable stainless steel wires with like sized screws in place.  Stainless steel tank (with lid) on propane burners (2), wires in tank and thermo steady at 600*.  Completed nitre blued screws and small parts to the left side of completed rust bluing.  All parts for a custom Hagn actioned .30-06  There are still two benches open for Metal Prep, Rust & Nitre Bluing class the last week in June, in Montana just when the rivers should be coming down to fishable! My work shop in located 1/4 mile from the Famous Yellowstone River~~

|

|

|

|

|

Joined: Dec 2008

Posts: 277 Likes: 4

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 277 Likes: 4 |

El Garro

The PID controller has adjustments for +/- 10 deg F. So it will bounce around in that 20 deg range, as far as learning, I donít think itís learned much



I really like the fact that I donít have to ďbabysitĒ the nitre tank, turn it on, set the temp, go do something for an hour while it gets to temp, nitre blue, turn it off.

Just wish I could find a larger melting pot.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

All this has gotten me thinking. Rather than using my kiln, I'm considering using the burner I use for my vertical barrel boiling tank. It's a high output wok burner using natural gas. It's in my basement, so I've ordered a higher CFM exhaust fan for my ventilation system. I have a large cast iron Dutch Oven to put the salts or lead in. It should be able to go up to 830 with no problem. I should be able to shoot the temp easily with my infrared thermometer.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Dec 2001

Posts: 6,992 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,992 Likes: 402 |

I usually warm the salts to the melting point on an electric burner then put them in the kiln at a set temperature. Many ways to skin a cat. I like this method because I do not need to watch it that close and can be multitasking.

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Thanks for all your input and pics everyone, reading between the lines it would seem we would all like to keep the pot at a constant temp so we can concentrate on the colour rather than juggling temp controls, it makes sense really.

The electric hob is here now but I ended up finishing the parts on the gas stove to save time, as soon as the bench is clear and there's time to do some experiments, I'll give it a go and see how good (or bad ) the temp control is. I'm tempted to try the pid controls but may get an electric lead melting pot and fit the sensor and controller to that, hopefully I'll find a way to save some time and produce consistent colours.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Look at this on eBay† http://www.ebay.co.uk/itm/182373517874 one of these kits is on its way. I'll try it on the cheap hotplate and see how it performs. There's more suitable temp probes on the same site which are a couple of quid so will use one of those rather than the type supplied. If it's successful it will end up fitted to a lead melter. It won't do too high a temp but should be ideal for blues. If I need to go higher I'll use gas and my twin channel k type digital thermometer used on the caustic tank.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Where do you plan to attach the thermocouple? Will you put it in the salts?

That's somewhat similar to the one I bought for my kiln, except mine has more components since it's 220 volt.

Regards

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

OP

Sidelock

Joined: Mar 2012

Posts: 617 |

Hi ken, yes, will make a bracket to hold it to the rear of the pot. Won't use the type that comes with the kit as I have the fine wire type. I hope it works after all this  Saw a Lyman big dipper lead pot at a good price but can't contact the seller until Tuesday as it's bank holiday weekend over here.

Rust never sleeps !

|

|

|

|

|