|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

7 members (bigblock, arrieta2, SKB, Southern Sport, Perry M. Kissam, 1 invisible),

1,152

guests, and

6

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,445

Posts544,844

Members14,406

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Does anyone have another source for soft steel carding wheels other than Brownell's? They are out of both the 2 and 4 row, and have been for a while it seems. Anywhere else to look for one? I'm not coming up with anything.

I can keep going with doing it by hand all the time, but there's some growing joint discomfort, and since I have a Baldor pedestal polisher on hand, why not use it?

Thanks.

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 617 |

http://www.thepolishingshop.co.uk/acatalog/Vertex_Type_Wheels-p1.html Shipping costs may be a problem but here's where I get mine from. May be worth an email to find out costs if you can't source any in the states. May also be worth a Google search for vertex carding wheels ? Good luck.

Rust never sleeps !

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Searched. Just in the UK it seems. Found some wire wheels at MSC here, but they're twisted strands and aggressive. The soft and fine Brownell's model is what I'm wanting to find.

|

|

|

|

|

Joined: Sep 2013

Posts: 320 Likes: 4

Sidelock

|

Sidelock

Joined: Sep 2013

Posts: 320 Likes: 4 |

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Yes! But out of stock. I imagine that these are the same as Brownell's, which are out of stock. Whoever makes them needs to get busy and do that.

|

|

|

|

|

Joined: Jan 2002

Posts: 2,307

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 2,307 |

I have had one back-ordered from OttoFrei.com since December, with still no word as to when it might ship. My current wheel is worn to a nub. I agree that the manufacturer needs to crank out a batch.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Here's one source. There's plenty of others out there. Easy to find, they're made by Grobet in a wide variety of sizes and types, and sold by several firms. http://www.danytools.com/abrasives.phpRegards Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

A little too coarse. It's .008", you want to be down around .003" for carding..

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

The real problem with using wheels is that if you don't have the ability to run them in both directions they fray and bend out of shape rapidly. That and it's very helpful to have the ability to run them at various speeds. I've gone to mounting them on a VSR drill. I also dress the wheels with a file card. They last much longer that way.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

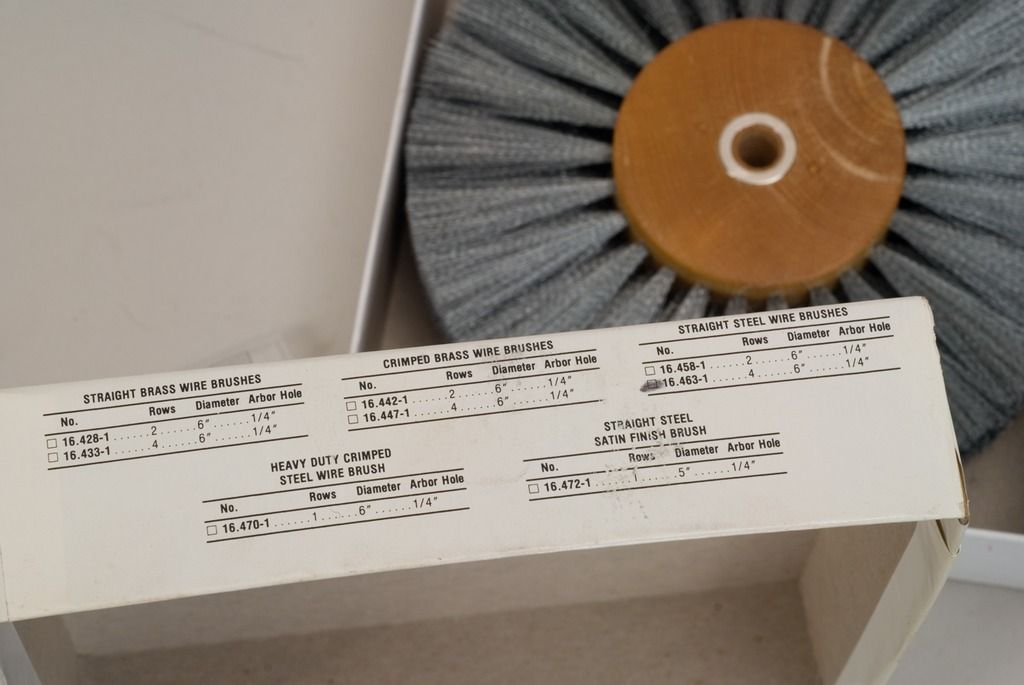

I am offering a seminar in Metal Preparation: Rust and Nitre Bluing for custom gunmakers. I do not do double barrels in class because of all the possible problems. I do teach the complete methods for rust and nitre bluing. I have room for two student starting the last week in June in Livingston, Montana. Here are the details: http://www.doublegunshop.com/forums/ubbthreads.php?ubb=showflat&Number=474289#Post474289In Class, parts ready to card, perhaps the third coat, at least 3 more to go.  I've been using this brand of wheel for more than 3 decades. This is a brand new spare I purchased more than 20 years ago. It may give you some notion of the manufacturer to source.  End Label of box, note it is Straight Steel, #16.643-1, 6", 4 rows of bristles, .003" wire diameter.

Last edited by SDH-MT; 05/07/17 04:36 PM. Reason: edit

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

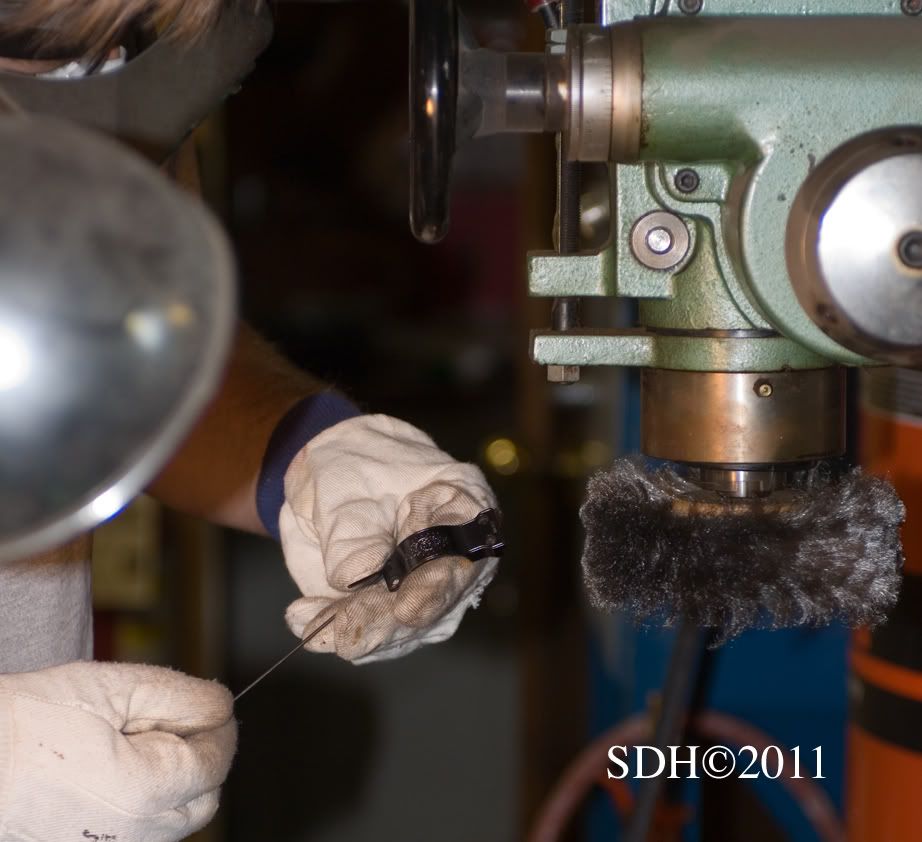

This is the wheel I'm now using and have used for many years. I run it in one direction and find that until the wires crush like this it is way too aggressive for the finish I'm looking for. The wheels take a lot of break in to achieve the correct softness.The speed they card at is also paramount to a super smooth and shiny finish.  In use carding a finely engraved scope ring half.

Last edited by SDH-MT; 05/07/17 05:03 PM.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

IMHO, blacking fluid steel is very different than pattern-welded barrels. I use completely different types of wheels for each, and even yet different ones for Brown & White. Fluid steel is considerably easier, with the one exception being barrel prep, with the final grit being much higher. I have found that ragged wheels in some instances can leave scratches in the finish, and also lose considerable efficiency since Damascus and Twist require a little more aggressive carding, depending upon the rusting stage. It's much more of a build-up, tear-down process, necessary to achieve both pattern clarity and high contrast.

Just a little clarification between fluid steel and pattern-welded tubes, I also use a similar, six-inch wheel mounted in my drill press running in one direction for fluid steel. However, I don't use it for Damascus or Twist.

Regards

Ken

Last edited by Ken61; 05/07/17 08:19 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

First reason I'm looking at adding a wheel to my option is arthritis. Carding with steel wool for much of the day hurts the next. When I get the Baldor set up and wheel on it, I'll make the wise choice and test on my own pieces first.

I've also got a slow-moving drill press to run if need be. The hold up as been the wheels.

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

If your Baldor runs 3250 rpm it would be way too fast for anything I would be carding.

Even 1750 is a might fast for my work.

Ken, maybe you could share with us what wheels you use for "pattern welded"

or damascus steel?

Last edited by SDH-MT; 05/07/17 09:40 PM. Reason: edit

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Here's my pattern-welded barrel carding setup. The wheels are .003 wire, three inch diameter wheels with one inch wire length. One wheel has four rows, the other has two. They are mounted in VSR drills. The four row is used for the overall tubes, the two row specifically for rib joints and lump/hanger areas. The drills are leaning on the barrel fixtures, designed so the barrels can be rotated easily during the process. The steel comb and file cleaner are used to dress the wheels between each set. So far, those wheels have done around 40 sets. With the tubes mounted with breech to the left, and working from the center of the set, wheel rotation when working towards the breech is clockwise, so they "roll off" when at the edge rather than coming down on it. Reverse for the muzzle, wheel spinning counter-clockwise. I use corded drills, but when using cordless, it would typically take one entire battery charge (18 volt Dewalt) to do one set. The paint brush is for dusting after carding. Once done with the wheels, it's important to go over the tubes with 0000 steel wool. They should feel slick. Areas with "drag" need additional carding, either with the steel wool or with a wheel. Regards Ken

Last edited by Ken61; 05/09/17 06:45 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jul 2005

Posts: 2,398 Likes: 16

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 2,398 Likes: 16 |

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

If your Baldor runs 3250 rpm it would be way too fast for anything I would be carding. Even 1750 is a might fast for my work. I found a variable speed controller from Harbor Freight that states it will work for 15amp and below motors. In a demonstration video, the fellow is using it with a router table. The Baldor is not in front of me to look right now, but I also have a slower drill press I can use when I get the wheels. https://www.harborfreight.com/router-speed-control-43060.htmlWish I could make a trip to Montana for one of your classes.

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

....I found a variable speed controller from Harbor Freight that states it will work for 15amp and below motors. In a demonstration video, the fellow is using it with a router table.... Check first before you buy it. That style of variable speed control is meant for universal type electric motors, the kind with the brushes. If you have a Baldor, it probably has an induction motor. Best of luck with it.

|

|

|

|

|

Joined: Dec 2008

Posts: 277 Likes: 4

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 277 Likes: 4 |

That speed controller will most likely NOT work with a buffer, especially not a Baldor.

I ran into the same issue several years ago, where I wanted to slow down buffers and belt sanders. I called several companies that specialize in custom made motor controllers, they all stated that trying to electronically control the speed on single phase motors, would quickly burn the motors up.

I finally solved the issue by going with 3 phase motors and adding a Variable Frequency Drive (VFD). Now I can go as slow as 1 RPM or as fast as the motor is rated with no loss of HP, and no fear of burning up the expensive motors. Three belt sanders and two buffers in the shop, now all with VFDs and 3 phase Baldor motors. Donít know how I ever lived without it.

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

That speed controller will most likely NOT work with a buffer, especially not a Baldor. Thanks. The unit didn't really cost me anything, but that doesn't mean I care to waste it by burning it up. I'll leave well enough alone and find another unit that's slower.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,461 Likes: 207

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,461 Likes: 207 |

I just use a double ended mandrel, with a large pully on one side, powered by an old washing machine motor. Old school solution, but cheap and easy. You can make any speed you need, by varying size of pully.

Mike

|

|

|

|

|

Joined: Dec 2011

Posts: 908 Likes: 43

Sidelock

|

Sidelock

Joined: Dec 2011

Posts: 908 Likes: 43 |

I have had good results using a bench top drill press. I typically set it at the second highest speed. Depending on the barrel steel I can get a nice bright finish. In my experience carding too much is better than not enough. YMMV

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

I have had good results using a bench top drill press. I typically set it at the second highest speed. Depending on the barrel steel I can get a nice bright finish. In my experience carding too much is better than not enough. YMMV I've got a press that runs slow, but it does not have any variability control. I've got a pair of wheels coming, so I'll have some options to try between the press and the polisher.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

One thing I want to mention is when using these wheels is the necessity of using eye protection and a dust mask. Often, small pieces of the wire break off. They usually end up in your hands, but I have actually had to pick pieces out of my fore head.

Besides wearing protection, you should always have tweezers, a needle, and a source of magnification handy to get them right away, before they go deeper into your skin and cause infection.

Regards

Ken

Last edited by Ken61; 08/09/17 11:34 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|