|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

|

Forums10

Topics38,502

Posts545,501

Members14,414

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Feb 2002

Posts: 1,851 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,851 Likes: 150 |

"...I degrease all my wire wool in acetone. Leave them to soak for a while then take them out and let them dry naturally. I always thought thatís enough but could be wrong..."

I think this may be the source of the problem afterall.

I've never been able to completely degrease steelwool,,not with acetone, lacquer thinner, hot soapy water & rinse or any combination.

( I guess you can buy degreased steel wool or stainless steel wool to avoid the problem,,I just never use the stuff to avoid the problems)

It may seem clear of grease after a good soaking in solvent (don't try burning it off!!), but a single speck in there somewhere rubbed out over the bbl when carding will coat the steel like you've purposely oiled it for putting up in the gun cabinet.

Certainly not what you want for rust bluing. Your water tank is then contaminated as are your soln container and applicator, ect from it. Even your gloves if you're wearing any.

Try carding a test piece with nothing more than a clean piece of canvas, denim cloth, burlap, ect. Even a piece of the fine scothbrite (white or maroon color). It might not be the most efficient but it'll at least tell you if you have color to the steel under the converted rust and it's staying put cycle after cycle. The converted blu/black fine coating should brush right off even with a swipe of the fingers leaving the color intact.

Worth a try, don't cost nuthin' to try..

A carding wheel then or in the least carding brushes if that's the problem.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

JMH Living as you do here in the UK and purchasing Lab grade distilled water. I hope you don't mind me saying it is a little like taking "Coal to Newcastle" the sky does all the distillation for you, just collect rainwater it is extremely cheap and we do have a lot falling on this island. Just strain it through a clean cloth and failing that the water from a home de humidifier I can also recommend to. I have used nothing else for many years.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

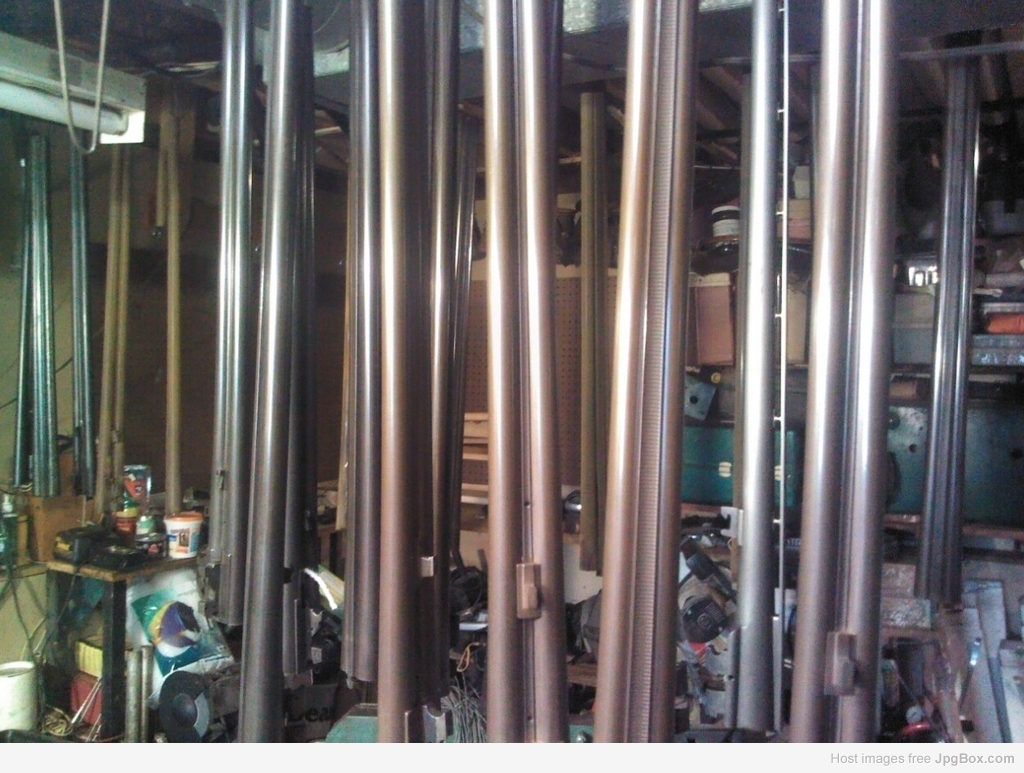

Second the rain water. I keep a 55 gallon drum of it and strain it through filter paper. I use it both for solutions as well as boiling. I've never had any issues with my degreased steel wool. I do also periodically wipe the barrels with acetone, but especially after prep before the first rust/etch. My current "Barrel Forest". No coloring problems.  Regards Ken

Last edited by Ken61; 03/18/17 06:32 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Sep 2011

Posts: 150 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2011

Posts: 150 Likes: 2 |

Taking the rust bluing to the next step, what do you use to finish the barrels?

Have used linseed oil on browned barrels and 30W non-detergent motor oil on blued barrels.

Let both set over night then wipe clean.

Chuck

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Taking the rust bluing to the next step, what do you use to finish the barrels?

Have used linseed oil on browned barrels and 30W non-detergent motor oil on blued barrels.

Let both set over night then wipe clean.

Chuck I refer to that step as "Curing". It's also a neutralization process as well. I use a 3 1/2" PVC tube filled with 50/50 used motor oil and kerosine. Used motor oil has the silicone burned out of it. I filter the oil through aquarium filter floss before mixing with the kerosine. I heat the tubes up with a heat gun before immersion. This deepens the color and toughens the coating. I soak at least overnight, then let drain. After that comes polishing and lacquering. (Damascus & Twist, unnecessary for fluid steel) You can actually see the PVC tube and a bag of floss in the lower left corner of the picture. There are three cured sets hanging above the tube. (More to the left, off-camera) Even though the pic color is off, you can see the sets are very black. Regards Ken

Last edited by Ken61; 03/19/17 08:06 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Now that is definitely what I call a barrel forest. Well all I can say you must be getting something right with that much work on. I can see in the corner that they look jet black. Iím deff not getting that colour. Firstly, I can see your letting them rust without a damp box and they look like theyíre getting a really good rust coating. Much better than I have achieved. The only positive thing I can take out myself is that the colour of the rust looks about the same Iím getting, dark orange red.

Ken would it be possible to get some photos of the different stages E.g. first rust coat and boil then say 3 or 4 passes down the line. Just need something to guide my progress off. If you canít I understand as you must be busy doing that many.

Iím pretty certain itís a solution problem but Iíll try with some clean denim or canvas on the carding.

Iíll try the rain water as well because we are definitely not short of it in the U.K.

Thanks for the help

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

All those tubes in process are Damascus, except for one Twist set. It's a different process from Fluid Steel. The two SBT tubes in the pic are Whitworth fluid steel, but I'm waiting on a minor issue before I can color them. Once That happens I can post some pictures of them.

I'm well along with the others, and, as I said, the process is considerably different than with fluid steel.

With Damascus, I like to do several rustings without boiling first,

so I'm sure the pattern is correct before boiling. The nearest sets are Parkers, due for their first boil next. The three sets hanging by the cured ones are being browned, so will never be boiled. In the pic they haven't been carded yet. If you're getting a similar rust coating, you're probably on the right track. It just takes many cycles for the black to deepen.

Regards

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|