|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,467

Posts545,110

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Hi everyone,

So I was wondering if anyone could help me on some rust blueing troubles.

Basically I�m struggling to get the deep jet black colour and currently only getting a light black/grey. I�ve read Angiers book and decided to try a few formulas out but with pretty much the same results. I�m getting no streaks or blotches, so happy with my degreasing and application of the solution but just the colour.

Ive tried C.17 swiss black (beutel), C.19 ferrobronze and C.10 Twist barrels K Birmingham black. The first rusting is a good coat of brown/red rust and takes 4ish hours in a sweat box of 40C and 80% humidity to form. I then boil for 15mins in distilled water to convert the rust and card off. This gives a light grey colour. The second rust coating takes a little longer and not as thick but you can see it�s there. I then repeat the process in boiling and carding and get a darker grey. The third coating then takes a good 18 hours plus to get a little bit of rust and after boiling hardly changes the colour. The forth coating barely puts any rust on the part at all, after 24hours in a sweat box. I believe this is where it�s going wrong in obtaining a real deep black and was wondering if anybody else has had these problems on the 4th application.

The only things I can think of are:

The test pieces I�m trying it on first, before my own William Powell shotgun barrels are walther rifle barrel off cuts and may be high in chrome and nickel making the solutions ineffective. However I know people in the UK can rust black walther barrels with amazing results so not sure about this one.

Or maybe im getting the boiling wrong, maybe too hot or for too long, causing the metal to reject the next application (trying 5 mins boiling time as I write this now)

Was also thinking of increasing the solution concentration by adding less water than what Angier quotes to see if this will get me better rust coats on the 3rd and 4th application.

Apart from that I�m out of ideas and any help from the more experienced rust blue �ers on this forum will be much appreciated.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

At this point, I'd guess the issue is with the composition of your test barrel. I regularly use C.10 and C.19 for blacking, both yield good results. In fact, I usually begin diluting the solution after the third application or so, because the black is so deep it's harder to etch. (C.10 used on Damascus and Twist). Having problems with C.19 is also surprising, as IMHO it produces an exceptionally deep black on fluid steel barrels.

The only other thing I do differently than you is allow longer rusting times, with four to six hours of moist heat, followed with dry heat throughout the overnight. I use shorter periods much farther down the process, after the color has been established and I'm trying to maintain contrast. (Damascus and Twist).

I suspect, though I'm not certain, that an Aqua Regia mix (HCL and Nitric Acids, along with Iron) is reactive enough to color some rifle barrels. It's certainly unnecessary for Vintage shotgun tubes.

Regards

Ken

Last edited by Ken61; 03/06/17 12:11 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Hi ken

Thanks for the information. I�ll try an aqua regia solution on them and see how it progresses. I remember reading somewhere that this can slightly matt the steel so I avoided it cause I�m aiming for a high polish finish but now you recommend it I�ll have a go.

I�m also going to find an off cut of some shotgun tubes and try the ferrobronze mix on them as well. This should be more in-keeping with the barrels i eventually want to black. I guess I thought one mix should work on most steel but this clearly is not the case and you have to adapt to which barrels you want to black.

Thanks for your time and knowledge

|

|

|

|

|

Joined: Jul 2012

Posts: 4,463 Likes: 207

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,463 Likes: 207 |

JMH,

I'm not as experienced as others here, but something to think about is the polishing. Sometimes steel will not color properly if polished too highly, especially if hard. I have trouble with Mauser bolt shrouds highly polished , by hand. Re-polishing with 320 grit cloth corrected the problem. If you are polishing them with a "wheel", I suggest you try a sample polished by hand, with worn 320 cloth.

Mike

|

|

|

|

|

Joined: Feb 2002

Posts: 1,850 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,850 Likes: 150 |

Try your soln just as it is along with your rusting temp, time and humidity,,but on a plain piece of hand polished cold rolled steel. I'll bet you get some nice results.

Your Wm Powell bbls won't be far off from that anyway in how they respond.

I suspect those Walther bbl cut offs are either stainless steel of some high corrosion resistant alloy from the way they are coming out w/a grey color and less rusted as you go along.

Maybe they need an etch coating first before the bluing soln will 'take'. Maybe they'd respond to an Express Blue better,,All sorts of little things happen that you end up sorting out over time. But when starting out and wishing to do plain older steel bbls,,you certainly don't need that stuff in your way.

Less boiling time hasn't ever been a plus in my experience. They do need some time in the tank to convert.

Leaving them in an extra long amt of time doesn't seem to gain anything though. I usually let a set boil for 10 to 15min then out it comes. It's as dark as it's going to get at that point.

|

|

|

|

|

Joined: Sep 2011

Posts: 150 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2011

Posts: 150 Likes: 2 |

Don't know about shotguns, but for rifles using one of the nitric acid, HCL mixes, limit the rusting period to no more than three hours.

Longer rusting will definitely etch the barrels. nice matte finish.

This is in a heat box at about 90�F with damp towels inside.

Chuck

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Thanks for all the replies.

I�m polishing to 600 grit and smooth over with grey scotch brite to blend it all together. It gives a sort of burnished effect. Would this be an issue to get the first coat to bite I wonder? I�ll try a 320 finish as you suggest with no scotch brite.

I had a look on lothar walther website and they use a Chrome-molybdenum type steel coded LW19. I�m pretty sure my off cuts aren�t stainless steel as they are magnetic and accept the usual cold blue touch up paste which I use to check if the metals will most likely black. It�ll be nice to see if I can solve this problem with these off cuts but I think the steel is completely different to the ultimate goal of blacking the William Powel barrels so I�m going to source some new test pieces.

I know Johnsons barrel browners can rust blue the walther barrels with amazing results here in the UK so it must be possible but I guess they�ve had generations to perfect the art and do it for a living.

Well I�ve got a few more things to try now, might take some photos at the different stages, to upload here, and see if you guys can spot something obviously wrong.

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

My final polish is with the Gray 7448 PRO pad, so that's not the issue. I use the Maroon 7447 PRO pad before it. After the tubes have been polished to 320. (Damascus and Twist) It's the steel.

Cold Blue is nothing like the rust bluing process, it's a coating which typically includes Copper Sulphate.

600 grit is not unreasonable for Fluid Steel, 400 is considered the minimum for Field Grade tubes. For Damascus and Twist, you need a little texture for the solution to "Bite". You typically etch the tubes before your first rusting as well.

I agree with the previous posts that suggested the Walther sections were probably colored with a different type solution.

Regards

Ken

Last edited by Ken61; 03/06/17 10:21 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Ok I�m sorting some new test pieces out tomorrow and I�ll try ferrobronze on it.

Out of interest have you or anyone else tried Aa 22 Black brown solution. Angier rates it quite highly in his book and the ingredients are pretty easy to get. Maybe worth a try as well.

And one last thing, when I put the test piece in the boiling water it drops the temperature below the boiling point for about 15-20 seconds. It then climbs back and converts the rust, but would that initial drop in temperatures cause any detrimental effect on the metal colour? Just a thought.

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Interesting. HCL and alcohol are very reactive, in my experience, the alcohol evaporates quickly, concentrating the effects of the HCL, making it very corrosive. HCL is extremely prone to after-rustng, no doubt why Angier noted that neutralization was necessary. Possibly this is mitigated somewhat by the Bismuth oxychloride, which is essentially an inert white pigment. But, my experience with it was on Damascus and Twist, with solutions containing alcohol creating a thicker coat that is harder to etch. It may be totally suitable for Fluid Steel. If you try it, please post the results.

A temp drop of short duration is no big deal. You can actually achieve the conversion simply by pouring boiling water over tubes in a non heated container, but it requires several changes of boiling water.

Honestly, IMO, you're chasing the wrong rabbit down the wrong hole, and I recommend you go back to the methodology of your first test, but using the appropriate steel samples. I predict you will be successful.

What type of tubes does your Powell have?

Last edited by Ken61; 03/06/17 01:04 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

The William powell barrels are fluid steel but they�ve been sleeved so I�m guessing two types of metal are going to be at play here. Mind you, the original black has no different shades to it, so they must be similar

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

When you do your Powell, I'd go to 500-600, and skip burnishing with the pad.

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Sep 2015

Posts: 40

Sidelock

|

Sidelock

Joined: Sep 2015

Posts: 40 |

Go to Brownell and get there classic rust blueing, follow there instruction , Strip blueing in a pvc pipe 4in with cap on 1 end

dilute acid 50-50 with water,that will strip the blueing in 10 second, rinse well Polish with scotch brite pads ,wipe down with automotive type cleaner that has no petroleum product in it,apply rust blueing , My cabinet I keep 60% humidity and 70 deg

let rust for 3 hrs, boil and card with Brownells stainless steel

4 row wire brush,slow speed , Full strength 1-2 application

dilute as you proceed Less messy thann mixing chemicals

Lyons Gunsmithing

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

I would just like to add something to the discussion I have found over the many years I have been bluing and browning gun barrels. On guns made some 30 years before 1900 and up to the 1950s, barrel rust blueing always went well and with very little trouble even with changing rusting solutions. Then after the 1950s steel used in barrels started to have small amounts of Chrome Nickel and Cobalt added to name just a few, this started to cause me problems and the need to change rust bluing solutions to make things happen correctly. Though I did find that one bluing solution worked well every time and it stayed that way until I hung up the rubber gloves and let the younger generation take up the art of bluing and browning.

The bluing solution is named after the American gunsmith Hervey lovell it can be found in Angier's under rapid bluing solutions though it uses enough Mercuric Chloride in its makeup to kill an Elephant.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Sep 2011

Posts: 150 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2011

Posts: 150 Likes: 2 |

The best instructions I have seen for rust bluing are in Dunlap's "Gunsmithing" book starting on page 388, called "The Niedner Cold Blue".

Beautiful, tough finish. No Mercuric Chloride. Seems to work on all steels: mild steel, 4140, heat treated 4340, even casehardened steel.

Granted some react faster than others. Follow instructions or it will etch the steel.

Chuck

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Thanks for the replies.

Little update, sorted out some scrap barrel ribs to use as some test pieces and I�ve managed to get 3 passes on them so far. So far it seems they still want to develop a good coating of rust on the 3rd application, which is better than the last test pieces. Colour is still a greyish/ slightly black. I�m guessing it�s going to need at least 6 passes but I�ll wait and see.

I can only get the laurel mountain forge barrel brown and degreaser over here. The uk website of brownells doesn�t seem to sell the classic rust blue. Does anyone know the makeup of it? Might already be one Angiers recipes under a different name.

I have been toying with the idea of trying a formula with mercuric chloride in but the stuff scares me as I�ve read how toxic it can be and I have no training or understanding how to handle the stuff safely. Is the recipe your writing about Damascus on page 72 Ac6 Express Brown? Its got a foot note concerning H. Lovell and if so, it has got quite alot of mercuric chloride in it. I have looked for it and you can buy it here in the uk. Sort of tempted to try it if nothing else works.

If im not mistaken the Niedner formula is just aqua regia with iron in. I will give it a go on a test piece once I�ve mixed it up. Still sticking with ferrobronze at the moment.

Last question, has anyone had trouble with their solution because the chemicals they�ve bought have not been up to a certain quality. The copper sulphate and ferrous sulphate I�ve bought are technical grade only, which is quite low on the different grades of chemical you can buy.

JMH

|

|

|

|

|

Joined: Jul 2012

Posts: 4,463 Likes: 207

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,463 Likes: 207 |

JMH,

I'm sorry I missed the fact that you live in the UK. I suggest you take a small holiday, drive to the German gunsmith, nearest you, and see if you can acquire some of the German solution from him, or at least find a source for it. This is what I use, having brought it with me when I moved back from Germany. It usually gives good color with 3 or 4 applications. Alabama is not bothered by too cold weather, or too low humidity, though. Don't leave it overnight, at least boil it. You can card it later. BTW the solution comes in 1 liter containers.

Mike

|

|

|

|

|

Joined: Feb 2011

Posts: 1,405

Sidelock

|

Sidelock

Joined: Feb 2011

Posts: 1,405 |

I will jump in here and comment on the OPs original concerns and say that if you want an easy to use solution that will get you deep black color look no farther than Mark Lees express blue. In my opinion, once you use it, you wont want to use anything else.

A set of barrels can be done in 4-5 hours. That is start to finish. The boiling tank never cools down. And that is with running around 8 cycles.

But if you want to do it old fashioned and mix your own, then the above is not for you.

B.Dudley

|

|

|

|

|

Joined: Jan 2005

Posts: 389 Likes: 2

Sidelock

|

Sidelock

Joined: Jan 2005

Posts: 389 Likes: 2 |

I would agree with the Mark Lee express altho I've never used any thing elso, so have nothing to compare to. The only problem I've had was with an overpolished old revolver and I had to roughen it a bit. As a complete amateur, I've had excellent results in blueing worn areas only and in applying it over existing blueing. Always seems to blend in well.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

There's still something amiss. Today I coated, carded, and recoated 22 sets, all with C.10. I'm currently carding a second time, this is my break. My house is running around 60% humidity, and even so I didn't use the rusting cabinet. Something strange is happening with your efforts.

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

JMH yes it is the same bluing mixture on that page but also on page 73 "Old English blue" also known as "American trade Express Browne" this is just another variation of the mix. This high Mercuric Chloride formulation was very popular and used by many Birmingham trade barrel finishers in past times. There are many reasons for this but two main reasons where one you could from start to finish rust bluing a set of shotgun barrels in less than an hour. Two you could re-blue worn blue barrel sections without completely re-finishing all the barrel set as long as the original bluing was rust based.

Yes it has high Mercury levels though simple precautions will keep its detrimental effects to a minimum. Working under cover outside of a building is the safest when bluing with this type of express rust bluing method, or alternatively having a high level of air extraction from the work place.

I have used both methods to keep the mercury vapours down to an acceptable safe level, And at 70 I am not as mad as a hatter though the lady I live with may want to say a word or two about that! Though in my defence I would say it is the Mercury Amalgam teeth fillings I have been carrying around for more years than I care to remember.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2002

Posts: 2,857 Likes: 384

Sidelock

|

Sidelock

Joined: Mar 2002

Posts: 2,857 Likes: 384 |

dennis potter used an a formula from that book with good results.you could contact him and ask,i have used laurel mt and brownells and another that i cant remember all will work good luck

|

|

|

|

|

Joined: Jul 2008

Posts: 448 Likes: 4

Sidelock

|

Sidelock

Joined: Jul 2008

Posts: 448 Likes: 4 |

I use Jim Baiar's (Half Moon Rifle Shop) Gun Goddess formula. Excellent results.

|

|

|

|

|

Joined: Jul 2008

Posts: 448 Likes: 4

Sidelock

|

Sidelock

Joined: Jul 2008

Posts: 448 Likes: 4 |

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

I feel that I should say that not all the relevant information on the subject of gun bluing and browning is written down even in that Bible on the subject "Angier's." Also formulas passed from person to person weather verbal or written get changed a little and it is in certain cases understandable because we are trying to duplicate formulas in some cases two hundred years old.

Lets take the original "Niedner" formula, the subtle discrepancy is in the "wire nails" because when the formula was first used nails be them wire or any other form where made mostly from Wrought Iron and not as todays, made of steel. The formula works far better if bits of wrought iron or pieces of cast Iron are dissolved in the Acid.

Now the vexing subject of "Spirit of Nitre" or sometimes written "Spirit's of Nitre", then sometimes you come across "Sweet spirits of Nitre." The first are the same chemical substance, though the third is not in fact it was a very popular druggist's medication until it was withdrawn from public use caused by a couple of unfortunate accidents. Though the one thing they all have in common is the active ingredient "ETHYL NITRITE" this is also not available over the counter for public use, because it is part of the illegal drugs scene and is known as "Poppers." Now there are a number of schools of thought about Spirit of Nitre and why it is added to vintage bluing solutions Ethyl Nitrite is so unstable that it can only exist in Alcohol as a percentage. It is there to give the mixture a pleasant smell though I am not too sure about this. Though the one thing that people are not made aware of is that very often it is included in a formula containing Mercuric Chloride, the reason for this is simple Mercuric Chloride will not dissolve properly in water YOU MUST MIX IT WITH ALCOHOL FIRST and add it to the water, I have never seen this mentioned in how to make the formula up hence Spirit of Nitre may just be included just provide the needed Alcohol and a pleasant smell! So over the years I have used high percentage Alcohol and not bothered with Spirit of Nitre and found things work fine.

Now one personal little thing I do before I started browning Antique muzzle loading guns with English "common twist" or sometimes known as "skelp" barrels, to improve the contrast between the Iron and Steel I darkened the Iron with Tannic Acid first by rubbing the barrel all over a couple of times with an Acid soaked cloth this action also works well on Damascus barrels. This darkening of the Iron gives a far finer contrast between the Iron and Steel after browning. Though I will add it does not work for all Iron types but it is such a simple thing to do so it is worth trying.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2012

Posts: 617

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 617 |

My first thoughts is oil contamination. Are your carding wheels or wire wool thoroughly decreased ?

I use ferrobronze a lot and really like it . I believe there's a point, well before the metal can pit that the rusting can remove some of the black from the previous pass. Just like putting too much solution on (too wet) can do.

Chemical quality, I get a lot of mine from that auction site so given that most are 99% pure according to the label I would suspect that's good enough. I've always wondered what the other 1% is made up of though.

Rust never sleeps !

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Little update, I�ve tried some new test pieces and slightly better in colour but still not perfect. I really don�t think it�s the metal now and something to do with the chemicals. I have actually ordered a solution from a company here in U.K that states it�s the �Birmingham Black� formula and obtains a decent blue. I will use my original process and same test pieces and see if it works with better results. If so, I guess that�ll mean there�s a problem in my original solutions. I did get an email saying there mixing it and that it takes a few days to �wet out�. Never read that saying in Angiers book, does anyone know what that means? I�m guessing it�s to let all the chemical reactions take place before decanting down.

I degrease all my wire wool in acetone. Leave them to soak for a while then take them out and let them dry naturally. I always thought that�s enough but could be wrong.

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

How many cycles are you running your test pieces? The black builds slowly, on fluid steel it take typically six or so cycles before the black really deepens. You steel wool degreasing is fine, I rotate the pieces in the soak, so whatever piece I take out has been in at least 24 hours.

I let solutions set for a day or two after making them, with occasional agitation. It's not as important if all the ingredients are liquids. Using dry ingredients like copper or ferrous sulphates is a little different.

Are you using distilled water for your solutions? City and well water can both contain chemicals that can alter solutions, mainly calcium and carbon compounds, which can mess with the acidity of the solution.

Regards

Ken

Last edited by Ken61; 03/18/17 11:52 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

I use lab grade distilled water from quite a good company here in the U.K. I�m not so sure of the other chemicals though. I�m going to see how this solution works that I ordered and go from there.

I put 7 passes on the test pieces and got slightly better colour but the rusting times are still 24 hours plus in a humidity cabinet.

JMH

|

|

|

|

|

Joined: Feb 2002

Posts: 1,850 Likes: 150

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,850 Likes: 150 |

"...I degrease all my wire wool in acetone. Leave them to soak for a while then take them out and let them dry naturally. I always thought that�s enough but could be wrong..."

I think this may be the source of the problem afterall.

I've never been able to completely degrease steelwool,,not with acetone, lacquer thinner, hot soapy water & rinse or any combination.

( I guess you can buy degreased steel wool or stainless steel wool to avoid the problem,,I just never use the stuff to avoid the problems)

It may seem clear of grease after a good soaking in solvent (don't try burning it off!!), but a single speck in there somewhere rubbed out over the bbl when carding will coat the steel like you've purposely oiled it for putting up in the gun cabinet.

Certainly not what you want for rust bluing. Your water tank is then contaminated as are your soln container and applicator, ect from it. Even your gloves if you're wearing any.

Try carding a test piece with nothing more than a clean piece of canvas, denim cloth, burlap, ect. Even a piece of the fine scothbrite (white or maroon color). It might not be the most efficient but it'll at least tell you if you have color to the steel under the converted rust and it's staying put cycle after cycle. The converted blu/black fine coating should brush right off even with a swipe of the fingers leaving the color intact.

Worth a try, don't cost nuthin' to try..

A carding wheel then or in the least carding brushes if that's the problem.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

JMH Living as you do here in the UK and purchasing Lab grade distilled water. I hope you don't mind me saying it is a little like taking "Coal to Newcastle" the sky does all the distillation for you, just collect rainwater it is extremely cheap and we do have a lot falling on this island. Just strain it through a clean cloth and failing that the water from a home de humidifier I can also recommend to. I have used nothing else for many years.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

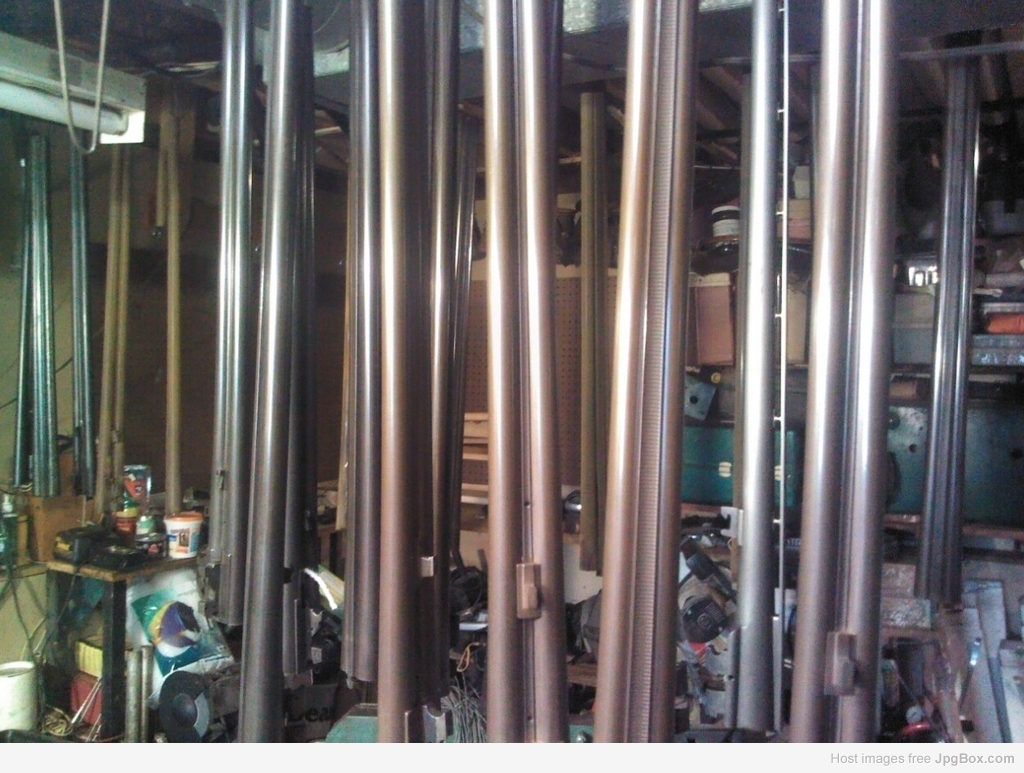

Second the rain water. I keep a 55 gallon drum of it and strain it through filter paper. I use it both for solutions as well as boiling. I've never had any issues with my degreased steel wool. I do also periodically wipe the barrels with acetone, but especially after prep before the first rust/etch. My current "Barrel Forest". No coloring problems.  Regards Ken

Last edited by Ken61; 03/18/17 06:32 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Sep 2011

Posts: 150 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2011

Posts: 150 Likes: 2 |

Taking the rust bluing to the next step, what do you use to finish the barrels?

Have used linseed oil on browned barrels and 30W non-detergent motor oil on blued barrels.

Let both set over night then wipe clean.

Chuck

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Taking the rust bluing to the next step, what do you use to finish the barrels?

Have used linseed oil on browned barrels and 30W non-detergent motor oil on blued barrels.

Let both set over night then wipe clean.

Chuck I refer to that step as "Curing". It's also a neutralization process as well. I use a 3 1/2" PVC tube filled with 50/50 used motor oil and kerosine. Used motor oil has the silicone burned out of it. I filter the oil through aquarium filter floss before mixing with the kerosine. I heat the tubes up with a heat gun before immersion. This deepens the color and toughens the coating. I soak at least overnight, then let drain. After that comes polishing and lacquering. (Damascus & Twist, unnecessary for fluid steel) You can actually see the PVC tube and a bag of floss in the lower left corner of the picture. There are three cured sets hanging above the tube. (More to the left, off-camera) Even though the pic color is off, you can see the sets are very black. Regards Ken

Last edited by Ken61; 03/19/17 08:06 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Mar 2017

Posts: 9

Boxlock

|

OP

Boxlock

Joined: Mar 2017

Posts: 9 |

Now that is definitely what I call a barrel forest. Well all I can say you must be getting something right with that much work on. I can see in the corner that they look jet black. I�m deff not getting that colour. Firstly, I can see your letting them rust without a damp box and they look like they�re getting a really good rust coating. Much better than I have achieved. The only positive thing I can take out myself is that the colour of the rust looks about the same I�m getting, dark orange red.

Ken would it be possible to get some photos of the different stages E.g. first rust coat and boil then say 3 or 4 passes down the line. Just need something to guide my progress off. If you can�t I understand as you must be busy doing that many.

I�m pretty certain it�s a solution problem but I�ll try with some clean denim or canvas on the carding.

I�ll try the rain water as well because we are definitely not short of it in the U.K.

Thanks for the help

JMH

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

All those tubes in process are Damascus, except for one Twist set. It's a different process from Fluid Steel. The two SBT tubes in the pic are Whitworth fluid steel, but I'm waiting on a minor issue before I can color them. Once That happens I can post some pictures of them.

I'm well along with the others, and, as I said, the process is considerably different than with fluid steel.

With Damascus, I like to do several rustings without boiling first,

so I'm sure the pattern is correct before boiling. The nearest sets are Parkers, due for their first boil next. The three sets hanging by the cured ones are being browned, so will never be boiled. In the pic they haven't been carded yet. If you're getting a similar rust coating, you're probably on the right track. It just takes many cycles for the black to deepen.

Regards

Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|