|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,463

Posts545,036

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

I know this may be a fools errand but what the heck. Hopefully I can get enough direction from the fine folk here that I can increase my chances of success (sounds better than lessen my chances of failure). So, here's the story. I have a early 1900s Meriden Firearms 20ga double. It is in sad shape but MAY be able to get back to firing condition which intrigues me. Although this gun may be rare since it's a 20ga it doesn't warrant sinking a ton of money in it. The stock is shot and missing parts so for the fun of it I thought I would try and carve my own replacement. I like wood carving, have a lot of tools and what will I be out except for my time. Note that this would be done on a lower priority.  From what I've read carving a stock for a sidelock shotgun is something that should only be tried after experience. This isn't likely to happen. So, with this all being said, anyone have any words of advice and wisdom they would like to share with me? Also, any recommended books to read? Thanks Kirk

|

|

|

|

|

Joined: Aug 2013

Posts: 388 Likes: 1

Sidelock

|

Sidelock

Joined: Aug 2013

Posts: 388 Likes: 1 |

Take your time, cut a little and measure often.

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

Maybe, that stock is good enough to patch and fill to make it into a pattern for a shop with a duplicator. I think you'll still have plenty wood working to do, but a good head start would probably come in handy. Best of luck with the project.

|

|

|

|

|

Joined: Jan 2013

Posts: 1,124 Likes: 195

Sidelock

|

Sidelock

Joined: Jan 2013

Posts: 1,124 Likes: 195 |

It will only be difficult if you let your imagination tell you that. Shaping wood is not "Rocket Science" measure twice cut once! As you have not given a picture of the whole stock may be you could do a head transplant with the joint hidden in the chequering, that will cut down many problems and of course the work. Doing it that way if things do not go to plan the firewood is minimal and so is the cost.

The only lessons in my life I truly did learn from where the ones I paid for!

|

|

|

|

|

Joined: Sep 2009

Posts: 80

Sidelock

|

Sidelock

Joined: Sep 2009

Posts: 80 |

I would make every possible attempt to join all the broken pieces into one " chunk". That should be sufficient to see what is missing and what needs to be done. And you would have something to use as a reference as Mr. craigd has suggested. Good wood glue and epoxy are your friends to get started here.

Since you have carving experience it should be clear sailing from that point on. Just take your time and set it aside any time you get a bit frustrated.

|

|

|

|

|

Joined: Oct 2014

Posts: 312 Likes: 1

Sidelock

|

Sidelock

Joined: Oct 2014

Posts: 312 Likes: 1 |

may be you could do a head transplant with the joint hidden in the chequering, that will cut down many problems and of course the work. Personal thoughts on a head transplant - Don't do it. With a butt transplant you can attach a large block securely before cutting it down less room for error. With a head transplant, a slightly different angle to original at the head can really throw out the measurements at the but end in relation to the barrel. Personally i have done it once, while the results are satisfactory and usable it did result in having to mess around with the other end of the stock to make it all as was. I came to the conclusion that this procedure is better left to others, by the time you have painstakingly inlet the head of the stock i wished i had just started with a blank canvas. - Just my experience. If i was to do it again, i would inlet the new head piece, and then alter the angle where it joins the but until the measurements were OK. As damascus says though a small piece of wood for doing a head transplant will cost much less than messing up on a nice blank..

Last edited by Demonwolf444; 11/29/16 11:21 AM.

|

|

|

|

|

Joined: Mar 2012

Posts: 347 Likes: 5

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 347 Likes: 5 |

It would be a fun project...especially when not pressed for time. Cannot remember where I read the info but carving from a blank is satisfying but you need to know how to lay out the various parameters for proper fit such as LOP, drop at comb and heel, cast and pitch. May as well make it fit you! I'm far from an expert but I have been successful not only making a Baker stock from a blank but I cut the blank from a walnut stump and had it drying in my shop for over 20 years. Much fun in the long run.

Just do some research and take your time.

And yes, I did have the old beat up and glued back together stock as a guide which helped a lot!

Last edited by SamW; 11/29/16 12:53 PM.

Sam Welch

|

|

|

|

|

Joined: Sep 2016

Posts: 42 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2016

Posts: 42 Likes: 2 |

Yup, that butt has seen better days. You may find Mike Yardley's book Gunfitting helpful. There is a pictorial featured here that's interesting. Sadly most of the best stock making books are no longer in print and extremely hard to find. Your method may differ but I would begin by piecing everything back together then tracing the outline of the butt on a knot free pine board. A chunk of 2x10 or 2x12 will be plenty wide enough to make a practice piece. One board may not be thick enough but two glued together will be. To judge the letting for the receiver and locks try lining the original with clear plastic wrap then use modeling clay to make a mock up of the original. Simply pack the clay in and around the letting. Be sure to have enough plastic wrap sticking out around the edges to pull the mock up out. The mock up will provide solid reference for the receiver end letting. Stock making, obviously, is both a skill and an art form. It takes practice and patience to learn the skill and develop the art. Practicing on a pine board is the best way I have found to do this. Keep us posted on your progress? Hank

Yes, I did write a book. It's called "The Classic English Double Barrel"

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Hello all, hope everyone had a great holiday season! I appreciate your replies and hope you don't think I blew you all off. I took some additional photos of the stock after gluing the parts together. It is relatively complete and I'm sure that with some fill here and there it be duplicated however I don't think this gun warrants the outlay of this much money.  Hank, I like your suggestion to mock it up with a 2x and considering that the stock is only 1 3/8" wide I can get it out of one piece of wood. In looking at the pictures, this narrowness is probably part of the problem. It looks so frail compared to a 12ga stock that actually has some wood left between the sideplates. When I get into it I'll try to leave as much wood as I can but my guess is that if it was possible they would have done it when they built it.     I've found what I think might be some books to purchase: Recreating the Double Barrel Muzzle-Loading Shotgun Clyde Baker's Modern Gunsmithing : A Revision of the Classic Professional Stockmaking: Through the Eyes of a StockmakerProfessional Stockmaking: Through the Eyes of a Stockmaker Modern Gunsmith: 2 Volumes In 1 Of the 4, I think the first might be the most helpful but I'd like everyones thoughts on this. As I side note I just saw that Hank has finished his book so there's another aspect to consider. Anyway, going to Menards tomorrow to buy some wood and we'll see where it goes from there. I'll try and make sure to keep updates coming Kirk

|

|

|

|

|

Joined: Sep 2016

Posts: 42 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2016

Posts: 42 Likes: 2 |

You did an excellent repair job Kirk. I agree, it does look frail. Judging from the pics it appears very dry and brittle but at least you have the original as reference to make a new one. Recreating the Double Barrel Muzzle-Loading Shotgun devotes a short chapter on stock shaping which may be helpful. The Classic English Double Barrel contains considerable information about how to carve a gun stock to fit the shooter. You may find it helpful too. I'm not familiar enough with the other two you mentioned, aside from knowing the book Professional Stockmaking: Through the Eyes of a Stockmaker is devoted to rifle stocking, to offer any input.

You have a fun project going. Just think, when it's all done you can step back, take a good look at it and say "Yes! I made this."

Hank

Yes, I did write a book. It's called "The Classic English Double Barrel"

|

|

|

|

|

Joined: Mar 2012

Posts: 347 Likes: 5

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 347 Likes: 5 |

When I re-stocked a Baker 16 I first fit the blank to the action and then inlet the side locks. I found I was able to leave a good bit more wood in between the two side locks than what the factory milling job had done. Once done perhaps you could re-enforce the wood with an epoxy coating?

Sam Welch

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Would this be one of those places where the new stock head would be well served by a judicious application of thin cyanoacrylate, soaked into the end grain, for strength? I've never done this, but have read of it on here.

SRH

May God bless America and those who defend her.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Hank, thanks for your insight. Is the stock building info in The Classic English Double Barrel more extensive than what's in Recreating the Double Barrel Muzzle-Loading Shotgun?

Sam, did a search for any posts on your Baker project but didn't come up with anything. Have any photos you can share?

Stan, you are probably right. I've used this in other woodworking projects and it definitely makes a difference. Maybe if I can leave additional wood and use super glue and/or Acra Glass I can make it more structurally sound.

Kirk

|

|

|

|

|

Joined: Mar 2012

Posts: 347 Likes: 5

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 347 Likes: 5 |

The CA glue will work quite well to strengthen and harden all the inside area of the stock. I know one custom maker who uses thin CA on the inside and outside of all his stocks. I use it myself some and was going to add that to the above post but here tis. Kirk, I went back and looked at my early posts and these photos are already available on a thread titled Batavia leader. The whole thread is of interest. http://www.doublegunshop.com/forums/ubbt...8247#Post318247

Last edited by SamW; 01/02/17 01:54 PM.

Sam Welch

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

Thanks for digging that up Sam, I remember thinking very nice job.

For practice, I think 2by pine could be frustrating to try to get crisp cuts. Maybe, a piece of poplar would be inexpensive and work just a little more like walnut. If the concern is the head of the stock, then the practice piece does not need to be full sized and include the butt.

Depending on how the metal fits, it could go quicker to inlet and glue in a little filler wood that's missing. Maybe let the metal back down, and refine it with some gel epoxy as needed, and get to a guide pattern to visualize if that's the hope.

I don't think you need to be overly worried about thickening the new wood beyond reasonable. I think some of these guns were fed loads that they never were really intended to fire.

Maybe, along with books, you can check youtube. Look up how folks are approaching lever action or single shot rifle butt stocks, and adjust here and there for your application. If the project stalls out, you could still have a shop semi inlet by duplicating off your pattern. The time commitment could never be justified in money, so a little money layout might allow someone to spend some time elsewhere on the project.

I think you may have a unique little gun. Thanks for the updates.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

For practice, I think 2by pine could be frustrating to try to get crisp cuts. Maybe, a piece of poplar would be inexpensive and work just a little more like walnut. If the concern is the head of the stock, then the practice piece does not need to be full sized and include the butt.

Depending on how the metal fits, it could go quicker to inlet and glue in a little filler wood that's missing. Maybe let the metal back down, and refine it with some gel epoxy as needed, and get to a guide pattern to visualize if that's the hope.

I don't think you need to be overly worried about thickening the new wood beyond reasonable. I think some of these guns were fed loads that they never were really intended to fire.

Maybe, along with books, you can check youtube. Look up how folks are approaching lever action or single shot rifle butt stocks, and adjust here and there for your application. If the project stalls out, you could still have a shop semi inlet by duplicating off your pattern. The time commitment could never be justified in money, so a little money layout might allow someone to spend some time elsewhere on the project.

I think you may have a unique little gun. Thanks for the updates.

Craigd, I was thinking the same thing about pine, especially after looking for anything that might have a reasonable grain. Ain't happening. I realized that I have a piece of tupelo gum that typically is light, fine grained and carves well. This particular piece is anything but light and is very dense/hard. Think I might look into using this. I also like the suggestion about filling in areas of lost wood to get a better idea of overall shape. The wood fit the receiver very well considering the shape of the stock. I also totally agree about the hot loads. I shudder to think about what I shot in my grandfathers 1917 Parker in my younger day. Sam, thanks for the link! I take a detailed look at the link and get back to you with the questions I know I will have. Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Sam, the Batavia post was interesting. I'm going to have to look at some of the old posts by Rocdoc. Sounds like he may have some experience. As for your work, it looks very nice. Good job and my only complaint is that there aren't more pictures!!! I can't believe you don't have a ton? If you don't want to through the hassle to post them you can email them to me.  Kirk

|

|

|

|

|

Joined: Sep 2016

Posts: 42 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2016

Posts: 42 Likes: 2 |

Hank, thanks for your insight. Is the stock building info in The Classic English Double Barrel more extensive than what's in Recreating the Double Barrel Muzzle-Loading Shotgun? You're welcome and yes, it is. Hank

Yes, I did write a book. It's called "The Classic English Double Barrel"

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

This evening I am going to cut out my practice stock. Wondering how proud the wood from the receiver? I was thinking 1/8" and would appreciate your input. Surely don't want it too much, just that much more to remove.

Kirk

|

|

|

|

|

Joined: Sep 2016

Posts: 42 Likes: 2

Sidelock

|

Sidelock

Joined: Sep 2016

Posts: 42 Likes: 2 |

3/16" to 1/4" will provide plenty "wiggle room" and just enough in case there's an "uh oh" in the lurch. Since it is a practice piece, if things don't turn out so good at least you'll know what not to do on the next one. A project such as this is so much fun and can be quite educational. I have a feeling you'll do just fine with it.

Hank

Yes, I did write a book. It's called "The Classic English Double Barrel"

|

|

|

|

|

Joined: May 2011

Posts: 742

Sidelock

|

Sidelock

Joined: May 2011

Posts: 742 |

Best thing I have ever soaked into a stock head was liquid acraglass thinned heavily with acetone. It soaked in like water and despite repeated soaking did not build up. It sealed and hardened like mad and is now my go to method to maintain shotguns against oil soaking and such. Steve

|

|

|

|

|

Joined: Mar 2012

Posts: 347 Likes: 5

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 347 Likes: 5 |

I agree with Hank in that as a first one it is better to have plenty of excess wood for those "Uh Ohs". With some experience you can drop that to 1/8 or even a little less. I also agree that it will be a fun and educational experience for you.

Sam Welch

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Took my chunk of dense tupelo over to a friends house to cut it down since his bandsaw has enough depth. This stuff is so hard he preferred that I didn't cut it there. He has a good saw but it has a relatively narrow blade for more intricate cuts. Started looking at what else he had and he just happened to have a piece of poplar with decent grain that was thick enough and long enough to get a blank which will allow me to mock up the receiver. Now the adventure begins.

Steve, like your suggestion about thinned acra glass.

Thanks

Kirk

Last edited by kirkp; 01/06/17 11:06 AM.

|

|

|

|

|

Joined: Feb 2005

Posts: 11

Boxlock

|

Boxlock

Joined: Feb 2005

Posts: 11 |

If you really want some interesting reading on sidelock/ sidelock plate and parts inletting get a copy of "The Gumsmith of Grenville County" (Building the American Longrifle) by Peter A. Alexander. If you are good with Acraglass Gel and spray release agent you can build-up the internal missing parts with that product (Brownells)

Believe me when I tell you it is not as easy as just removing all the wood that does not resemble a shotgun stock. It takes a lot of careful spotting-in and paring away as well as a minds eye for what you want the result to be.

Good luck!!

Ken @ padnchecker

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Ken, really appreciate the info on the book. I'll have to check it out, especially if in your opinion it gives some good direction on the process. Not hard to imagine based on my questions that "I am not good with Acraglass".

We will see how it goes with the stock. I'm not expecting perfection but I do have a good eye when it comes to replicating something. Maybe part of my engineering background. Hopefully if I go slow I'll be able to pull it off.

Pictures to come.

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

A bit of an update which I will probably make in a couple of posts since I hate when they get toooo long. First off I want to give a big thanks to Sam Welch (SamW) since he's been very helpful. He's given me a lot of info from when he worked on his Batavia along with a lot of photos. So, I've been contemplating my path forward maybe to the point of overthinking. I'm in the process of rebuilding the original stock to replace missing wood where it mates up to the receiver. I cut my practice blank out of some poplar which isn't the full stock length but will allow me to fit the entire receiver and trigger assembly. In a earlier post I questioned how much extra wood to leave and for better or worse I cut the blank out with 1/8" extra before getting the responses to leave a 1/4". Will have to make do I guess. I've been trying to get a decent pattern of the top tang. If I try to get the complete tang, it gets difficult at the end where the curves compound to match up to the receiver. I made a partial pattern where it's easy to trace and using my engineering skills  I was able to determine where it would fall on the stock. Still pondering my path forward as I work on repairing the stock.  Sam indicated that although it has been awhile he seems to remember that he started short and worked his way back.  As I was pondering the stock, I thought I'd assemble the receiver to see what all I'll be dealing with during inletting. In my opinion, there is so much packed into the small action that it's hard to believe that I'll be able to get much more wood.   Should be interesting to say the least. Have some more thoughts that I'll put in another post regarding the parts that need to be fabricated/modified. Later Kirk

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Shoot for the moon with your inletting, Kirk. What I mean is, attempt to leave every smidgen of wood possible, even if you've never seen anyone else's inletting like that. That way you'll end up with all that is possible, IMO. When I inletted this percussion side lock I left a little piece of wood that nobody leaves, as it really doesn't add much to strength. A mentor told me he'd never seen anyone leave that area, but was very impressed.  The little arrowhead shaped piece is what I'm referring to. It is inside a leaf spring that acts as the sear spring on the Schillinger lock.  Every little bit adds to the support surface area for the lock. Necessary? ..... probably not. Nice? ........ I think so. SRH

Last edited by Stan; 01/20/17 08:20 AM. Reason: error in text ...

May God bless America and those who defend her.

|

|

|

|

|

Joined: Mar 2009

Posts: 2,018 Likes: 50

Sidelock

|

Sidelock

Joined: Mar 2009

Posts: 2,018 Likes: 50 |

Michael Dittamo

Topeka, KS

|

|

|

|

|

Joined: Oct 2011

Posts: 207 Likes: 2

Sidelock

|

Sidelock

Joined: Oct 2011

Posts: 207 Likes: 2 |

Stan, you are a very lucky guy! I have 2 of Mr. Schillinger's beautiful locks. They are simply the best percussion locks I have ever seen. Every part made of the finest material and polished to the highest degree. Fitted perfectly and they deserve to be mounted on the best gun possible. One is for a 1 inch barrel and the other is for a 1&1/8 inch barrel. I bought them 40 years ago and still have not seen any better. His triggers and rifle sights were also of the highest possible finish. That "old man" could really make something!

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

....As I was pondering the stock, I thought I'd assemble the receiver to see what all I'll be dealing with during inletting. In my opinion, there is so much packed into the small action that it's hard to believe that I'll be able to get much more wood.... I'm probably seeing things wrong here, but maybe take things apart. Don't loose the fit to the back of the action at the head, but you may be able to let the top tang down into the wood instead of back. Then maybe add things one at a time. Maybe the bottom tang/trigger plate next, then side plates, and guts last. Only thoughts kirk, thanks for the updates.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Stan, that is one heck of a job you did and the level of detail is very good. To be honest, I probably wouldn't have left that piece but good for you. Certainly can't hurt being there. Craig, I appreciate your thoughts on this. You're not seeing things wrong. I just put the action together to see how much space was being taken up. This receiver is SMALL with a lot packed into it. It hasn't been very easy to get a good pattern of the top tang. The receiver has a squarish section under the tang that has to be let into the stock. In addition there is a nub (for lack of a better word) at the bottom of the receiver that needs to be addressed. This sort of makes me think that I need to get the tang let down into the stock and then work the receiver back until it mates up with the face of the stock.  Then as you say I'll start fitting all the other parts. Kirk

|

|

|

|

|

Joined: Jun 2006

Posts: 2,979 Likes: 296

Sidelock

|

Sidelock

Joined: Jun 2006

Posts: 2,979 Likes: 296 |

Typically, the "heading up process" starts at the rear of the action body. In the vertical plain.

I use a plexiglasss cut-out approximating my desired stock shape, and I trace it on the blank.

In that moment, I am identifying figure, knots, grain flow, and sap wood, to get what I want where. Slide the plexi glass around, see what is possible.

Here's where that impacts you.

The comb angle vs the plane of the rear of the action.

Your first plumb cut sets up everything else behind it.

Don't screw up the blank with the first cut.

When you have that plumb cut made, you can start letting in.

I cant tell from your pictures, but I think you'll be going ahead first, and then letting the top strap down into the blank.

Check out some You tube videos for AyA or Purdey's, they show enough heading up to see how to avoid a first cut malfunction.

Out there doing it best I can.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

CZ, thanks for the reply. Spent a bit of time looking through videos and while I've some things of interest, I've yet to find one that shows what I'm looking for. Lots of videos so I'll keep looking.

I'm going to take some more pics of the action from different angles and post them. Hopefully that will make it more clear what I'm dealing with that has me going Hmmmm.

Kirk

|

|

|

|

|

Joined: Jun 2006

Posts: 2,979 Likes: 296

Sidelock

|

Sidelock

Joined: Jun 2006

Posts: 2,979 Likes: 296 |

I thought you might reply.

I looked at the H&H video where they make a DR. 6:50 in you'll see the square cut head and the top strap being sunk in. Then the square mortise you are worrying about.

Lots of blacking and tapping.

The thing to remember is that these shotguns are machine made. There's a machining order that allows their quick manufacture.

Some have no draw between the plumb cut and the shoulders of the action, so the fit between them should approach perfection. Or they pound themselves.

Out there doing it best I can.

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

Kirk, I think what the example CZ is showing is that the top strap is rolled down into the blank until the back of the action meets his starting reference cut.

I don't think you can drop straight down and still be able to jump undercuts. Also, if you inlet the top tang, then work straight back to bring your reference cut filled in above your lower nub, the tang will climb out of its inletting because of its downward pitch.

Maybe, try it out on one end of your poplar, and flip it over to try a different approach if needed. You may not need to make a pattern of your tang, but it could end up being a bunch of scribing, rescibing and spotting.

|

|

|

|

|

Joined: Jun 2006

Posts: 2,979 Likes: 296

Sidelock

|

Sidelock

Joined: Jun 2006

Posts: 2,979 Likes: 296 |

I used David Trevallion's articles for guidance, starting with a Crescent, and a straight grained piece of walnut.

All that blacking is part of the fun.

Learning which tool can do what for you is part of the rest.

I could never be as aggressive with a gouge as a bench pro at Purdey's. They hog some stock. Absolutely merciless.

Out there doing it best I can.

|

|

|

|

|

Joined: Oct 2014

Posts: 312 Likes: 1

Sidelock

|

Sidelock

Joined: Oct 2014

Posts: 312 Likes: 1 |

It's well worth the time profiling grinding sharpening and honing all your chisels as sharp as you can on the best water stones you can afford (£20 from eBay works pretty well!) sharp tools rarely wonder rip out wood or slip and make an unintentional cut. Only remove the high spots. Don't let the soot build up too much.

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

Stan, you are a very lucky guy! I have 2 of Mr. Schillinger's beautiful locks. They are simply the best percussion locks I have ever seen. Every part made of the finest material and polished to the highest degree. Fitted perfectly and they deserve to be mounted on the best gun possible. One is for a 1 inch barrel and the other is for a 1&1/8 inch barrel. I bought them 40 years ago and still have not seen any better. His triggers and rifle sights were also of the highest possible finish. That "old man" could really make something! They are really fine locks, Eric. I have two of them, also. But, I have one other percussion lock that may well be built to a higher level of precision, though not as highly polished. It is a custom lock built by Bob Roller. It took me a half hour on the phone to convince him to build me one, many many years ago. Absolutely awesome, and a bit quicker lock time than the Schillinger, IMO. This particular Schillinger is on a 1 1/8" Douglas XX barreled, 13.9 lb. .45 cal. buffalo gun. It has shot 5/8" groups at 100 yds. Thanks for the comments. Good luck with the stocking, kirkp. Please take pics and keep us posted along the way. All my best, SRH

May God bless America and those who defend her.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

CZ, did some looking for the video you mentioned but have a question for you. What is a DR model or would you happen to have the link handy? I found this one https://www.youtube.com/watch?v=qUXoNUzAyvk where about 7 min in they are inletting a action but then in the course of a second they go to a different completely inletted action. If you take a look at the side view of the action I posted above, you can see a rectangular shape just under the tang. Also note at the bottom of the action where it isn't square but has a small radiused area. This creates a small point that needs to be set into the face of the stock. This leads me to think that the action has to be at the correct vertical height before it can go back. This next pic is a oblique view of the action which shows the rectangular section a bit better.  This last pic shows the action butted up to the stock for what it's worth.  You also mention some articles by David Trevallion. Where bouts can they be found? Craig, I like what I think you're saying about rolling the action back. Now just figure out how to do it. I was toying with the following idea. Use the tang pattern and position it where I am fairly certain it will end up. Start inletting it down to the correct depth. I was thinking that I could then start rolling the action back. Not sure if that's clear but it sort of jives with what appeared to be happening in the H&H video I posted. It would seem to me to be much easier if the face of the action was flat instead of having that little tip protruding. Well back to video searches for now. Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Found something tonight that might be of interest. I was messing around with the gun checking how far off face it was. I got to thinking about using the proper shells in the gun and how the depth of the chamber can influence this. Got me curious so thought I'd measure chamber length but as it turns out there isn't one. What I'm saying is that it wasn't bored out. Anyone ever seen anything like that?

Kirk

|

|

|

|

|

Joined: Feb 2008

Posts: 11,340 Likes: 389

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,340 Likes: 389 |

Found something tonight that might be of interest. I was messing around with the gun checking how far off face it was. I got to thinking about using the proper shells in the gun and how the depth of the chamber can influence this. Got me curious so thought I'd measure chamber length but as it turns out there isn't one. What I'm saying is that it wasn't bored out. Anyone ever seen anything like that?

Kirk How do you know it wasn't bored out? Have you tried chambering a shell, and found that it didn't fit? Is the breech end inside diameter of the barrels the same diameter as that of the bores? Or is there no recess for the rim of the shell? Or is it simply that you cannot see a step at the end of the chamber which might indicate that the forcing cone has been reamed out to a very gradual taper? If it is the latter, you may want to get those barrels measured for thickness at the end of the chambers before you bother with all the work of restocking the gun.

A true sign of mental illness is any gun owner who would vote for an Anti-Gunner like Joe Biden.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Hey Keith. Hmmmm, it's not 1 or 3. I can say with certainty that there is no step at the end of the chamber. How would one determine if it's 2 or 4? Wouldn't they look the same?

Kirk

Last edited by kirkp; 01/25/17 01:18 PM. Reason: correct a number

|

|

|

|

|

Joined: Nov 2015

Posts: 67

Sidelock

|

Sidelock

Joined: Nov 2015

Posts: 67 |

Colin Stolzer has videos on YouTube that completely document the process of building a double barrel Purdey style 10 bore. It's a muzzle-loading gun, and it uses side locks. If you still need some insight google video series "10 Bore 1844 Purdey Double Rifle". He has the whole inletting process explained, and recorded. It was a huge help to me.

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

huntingsgr8, I appreciate the reply. I'll check them out.

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

huntingsgr, so tell me, what did you build a stock for?

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

huntingsgr8, thanks for the info on the videos. There is a lot of info there and he goes into great detail. Got some serious watching to do.

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

In response to Keith's questions. I took a closer look at the barrels. While the majority of the barrels look good, the area that would be considered the chamber have either buildup of something or corrosion. Need to clean that are up. In looking at the barrels, I can see that there is a taper and no step at the end of the chamber. If I run a steel rule in, it appears to be flat for about 2 15/16" and then a taper starts which runs out to the bore diameter at about 3 1/4".

More later, I'm sure.

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

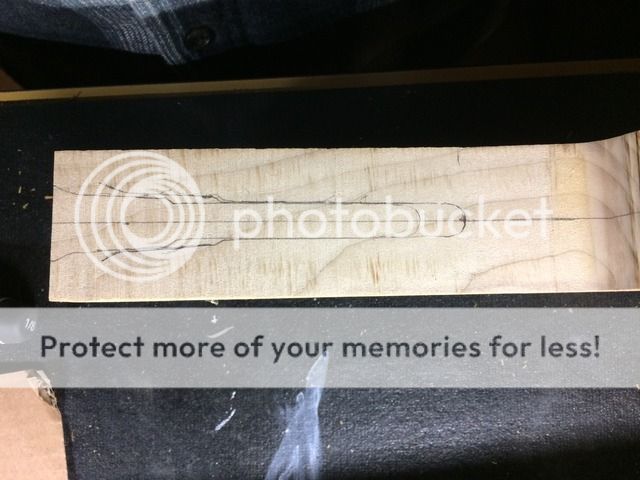

So been working on the practice stock off and on, probably more off. Seems there's plenty of stuff going on that keeps getting in the way. Think I might have too many hobbies. However I've been keeping my eyes open for a stock blank to use when I'm finally ready. I got to thinking about a bunch of walnut blanks my uncle had many years ago. Not sure where he got them but he was using them for caricature carving. He has since passed but talked to my cousin to see if he had any of them. Turns out he did and at least in my opinion not too bad. Need to make sure I don't screw it up. Comments/opinions welcome. Kirk

Last edited by kirkp; 04/02/17 01:26 AM.

|

|

|

|

|