|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,465

Posts545,065

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Mar 2006

Posts: 509 Likes: 3

Sidelock

|

Sidelock

Joined: Mar 2006

Posts: 509 Likes: 3 |

I found this old thread about 'bulges.'

The subject gun I am considering purchasing has 3 bulges in the right barrel, according to seller. From the breech - 14", 15 1/2" and 17". The first two are just 'barely' noticeable acc. to seller. The 17" is more pronounced.

The subject gun is a graded gun not only with the barrel issue of bulges but needs wood work as well. Wood can be fixed. Dents can be raised. But will there always be an inherent problem in the bbls if the bulge is repaired?

He does not know bwt nor has the tools to measure. No inspection or return. As-is.

I don't want to waste $ but I do have another set of bbls that could possibly be fitted to subject gun.

Can bulges be fixed and barrels still be considered safe?

Last edited by RedofTx; 01/21/16 06:48 PM.

|

|

|

|

|

Joined: Mar 2006

Posts: 509 Likes: 3

Sidelock

|

Sidelock

Joined: Mar 2006

Posts: 509 Likes: 3 |

thanks for looking at above post.

Last edited by RedofTx; 01/08/16 09:19 PM.

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 12

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 12 |

Red, there are very skilled "smiths" who can usually repair dents to the point of "almost invisible." Metal science wise, dents of modest size and shape pose no particular issue; they are not going to grow or suddenly rupture. Yielded steel is "stronger" than the surrounding unyielded steel.

The bug in the ointment is the case of a bulge in the between-the-ribs area. Then, the barrels must be disassembled to repair - - - think $$$.

To a collector, once damaged always damaged. To a shooter, howz she shoot?

DDA

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

Part of my education is manufacturing engineering. Over the years I've been involved in countless metal forming operations and processes. One that seemed to jump into memory was explosive forming aft pressure bulkheads on commercial aircraft. We'd use a high explosive in water to squash and stretch a large piece of metal over a domed shaped form and flange it as well.

I could go on all night on examples of structural aircraft parts that are cold formed.

I'm with Don on this one. If the bulge is inspected and crack free, it is much stronger than before it was bulged. I say this because there is actual metallurgical industry standardized test data that can repeatedly substantiate this fact, not a gut feel. I can produce that test data, but my internet is down and I'm working from my cell iPad.

Last edited by Chuck H; 01/09/16 03:18 AM.

|

|

|

|

|

Joined: Jan 2002

Posts: 11,377 Likes: 105

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 11,377 Likes: 105 |

I also remember reading,and I believe it was here, regarding owners of damascus barreled guns finding minute holes right through their barrels due to inclusions that were present from the original forging process. I think they had been shooting these guns for years without ill effects.

Jim Years ago, a friend and I were looking at a British 2" 12ga he was thinking about buying. Couldn't find any real issues other than some very small exterior pits (not holes) in the barrels, within 6" of the muzzle. We both thought the gun should be rejected on that basis. But after thinking about it a bit more . . . wait a minute! People shoot guns with REAL holes in the barrel out by the muzzle (ported barrels) all the time.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,416 Likes: 313

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,416 Likes: 313 |

Major Sir Gerald Burrard in the second edition of The Modern Shotgun (1948), Volume 3, The Gun and The Cartridge, “The Diagnosis of a Burst” discussed “Wave” Pressures and the etiology of multiple bulges pp. 364-375. p. 365 When the explosive charge was placed entirely at one end of the closed vessel (discussing experiments by Paul Marie Eugčne Vieille and published in Etude des Pressions Ondulatoires in 1890) the gases given off naturally rushed forwards along the length of the vessel until the forward layer of gases was suddenly checked by the closed end. When this occurred the gases which were behind the extreme forward layer over-took this layer and began to pile up against it, with the result that the extreme forward layer was compressed with great violence. It was this compression of the extreme forward layer of gases which caused the high pressure… p. 368 Since this wave pressure acts radially outwards the wall of the barrel is submitted to a very severe pressure all round its circumference, and if the pressure is sufficient to stress the barrel beyond the elastic limit of the steel a permanent bulge all round the bore is the result. Such a bulge is knows as a “Ring Bulge”... p. 374 If the wave pressure was not sufficient to burst the barrel...the shot charge and obstruction will continue to travel along the bore under the influence of the expanding powder gases, but the wave pressure will be reflected backwards and will occur again at the extreme end of the cartridge-case. It will then rush forward once more (third wave) and may overtake the shot charge...in which case it will act again immediately behind the wads. It is possible for the third wave pressure to be sufficiently violent to bulge the barrel some way ahead of the site of the first wave pressure, in which case one obstruction would be responsible for two ring bulges. Radiograph of 2 bulges  I believe questions 1 through 9 should be "What is the wall thickness at the area of the bulges?"

|

|

|

|

|

Joined: Dec 2008

Posts: 351 Likes: 2

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 351 Likes: 2 |

Red,

I am not sure about the barrel bulge, but I sure do not like the part about "No inspection or return. As-is."

That is always a red flag for me.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

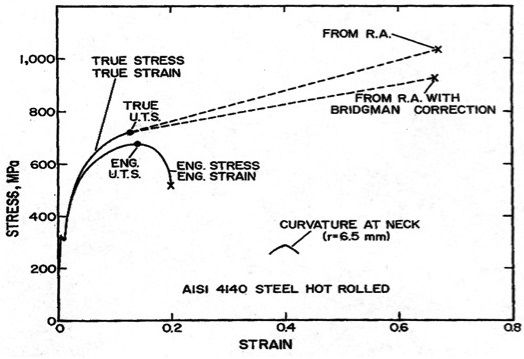

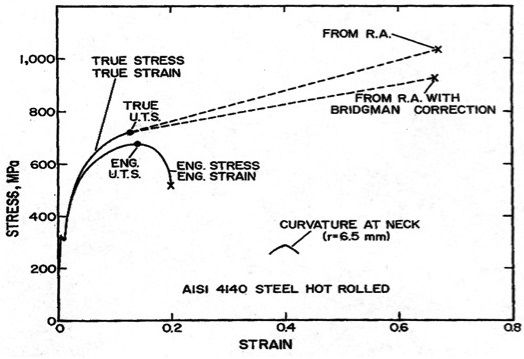

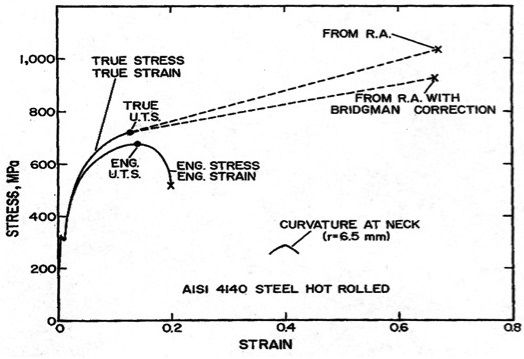

Here's a stress-strain curve with test vs corrected for section reduction true curve. At around 310-330 MPa, there's a little whoop-de-do along the left side of the chart. That's where the elastic limit is reached and permanent deformation begins. As the test coupon stretches, it necks down in cross section. The lower curve simply shows the test data, without correction for necking. The upper curve is corrected for necking. You can clearly see on both curves, once it (permanent deformation) begins, tensile strength increases and continues to increase until failure on the corrected curve. There are are other effects to fatigue and fracture resistance, but the question on the table was strength. So, as Drew pointed out, if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.

Last edited by Chuck H; 01/09/16 12:17 PM.

|

|

|

|

|

Joined: Feb 2009

Posts: 7,463 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,463 Likes: 212 |

....if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.  Is there a good way to determine if the strain value of .2 is approached or exceeded? Also, once the maximum stress is achieved, would additional movement of the metal, bulge or dent repair, move that area farther to the right on the strain curve? Is it better to shoot a bulge as is?

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

....if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.  Is there a good way to determine if the strain value of .2 is approached or exceeded? Also, once the maximum stress is achieved, would additional movement of the metal, bulge or dent repair, move that area farther to the right on the strain curve? Is it better to shoot a bulge as is? Craig The coupon fails at the UTS (ultimate tensile strength) point on the chart. To me, that appears to be in the area of 15-17% elongation.

Last edited by Chuck H; 01/09/16 02:32 PM.

|

|

|

|

|