This week I did the final shaping of each forearm and they are ready for the final sanding as soon as the screws are slotted and the heads can be brought flush with the exposed escutcheon surface.

Today the screws got slotted to properly index and the extractor cuts got done.

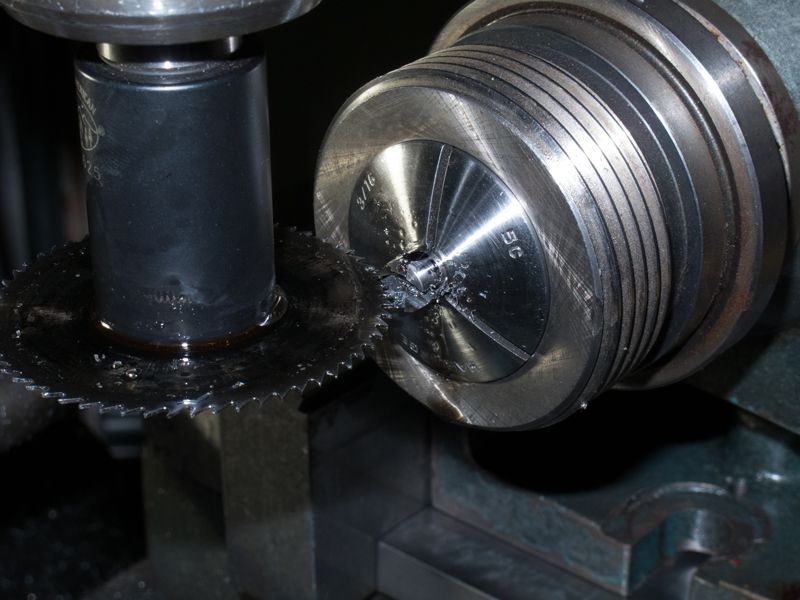

This is the setup using Morris' dovetailed jaw fixture which gripped the barrels in a perfectly aligned position.

Using a 1/8" end mill an indexing longitudinal cut was made so that each screw could be locked in a collet for slotting.

The screws were slightly under-indexed to ensure no over rotation when the screws are pulled down into the escutcheon with a bit.

The saw is .023" wide which will give me a screw slot that allows use of a thin bit.

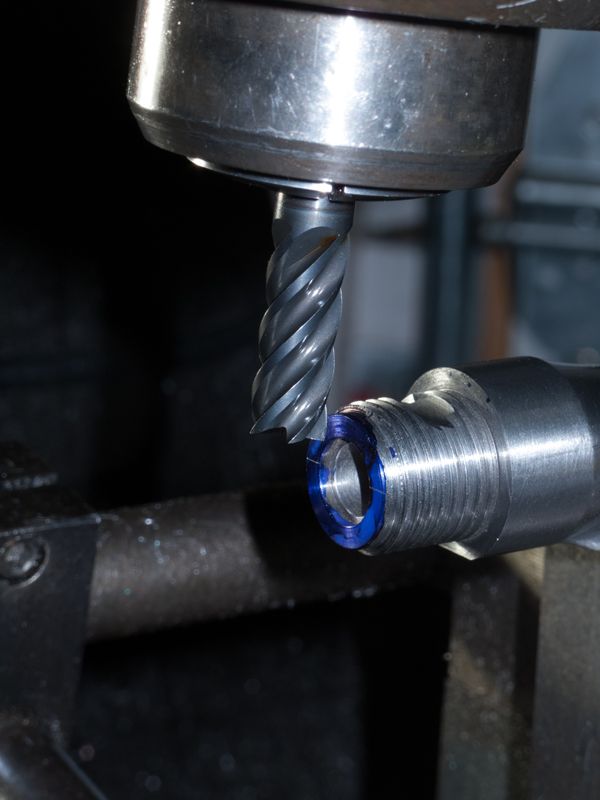

All of the forearms were removed and one by one the barrels were again installed in the dovetail fixture by the scope bases.

The top edge of this BSA Martini extractor cut is .032" below bore center and is tilted to the 6 o'clock position by 6 degrees. The mill head was tilted appropriately and cut with an end mill to the depth that would allow the original extractor numbered to the action to lie flush with the breach of the barrel.

Here is the completed cut.

Morris' metal work is simply incredible.

I finished shaping the lever, got it inletted, got a small Fisher steel grip cap installed and a lot more wood removed. I need to bring the comb height down about 3/16" to 1/4" and then the final shaping of the nose and cheek pad can be done. The wonderful photos on this website of Dubiel rifles gave me ideas about a pad shape and although an interpretation, it will be a shape I've never used on a stock. I don't know how all these photos will survive on this forum with the Photobucket dependencies but hope someone is paying attention to those details.

The lever end treatment has been finalized and I need to get a piece of round stock welded on. A Martini sold at Julia some time ago provided the inspiration for the design.

The action, barrels, escutcheons, butt plate, grip cap, sights and lever are scheduled to go to the engraver in February.

We are having historic high temperatures and hope to get outside and do some thickness planing of the mahoghany case pieces. I'd like to do blind dovetails on the top and bottom of the case and need to plan that out with everything at 5/8" thickness. I have all of the hardware now except some kind of lock for the case. All of the chest hardware is now here and have baize samples coming from England.

I ordered USA made brad point bits for the ammo blocks and the mould handles and three of the six have points off center or warped shafts. They have to go back as a firmly held wood block with closely spaced holes in a 5x10 pattern cut with wobbly bits will have off center holes that will be visible.

Dennis