With the escutcheons made and the forearms inletted the next step would be drilling and tapping the forearm barrel lug and then the forearm retaining screw hole.

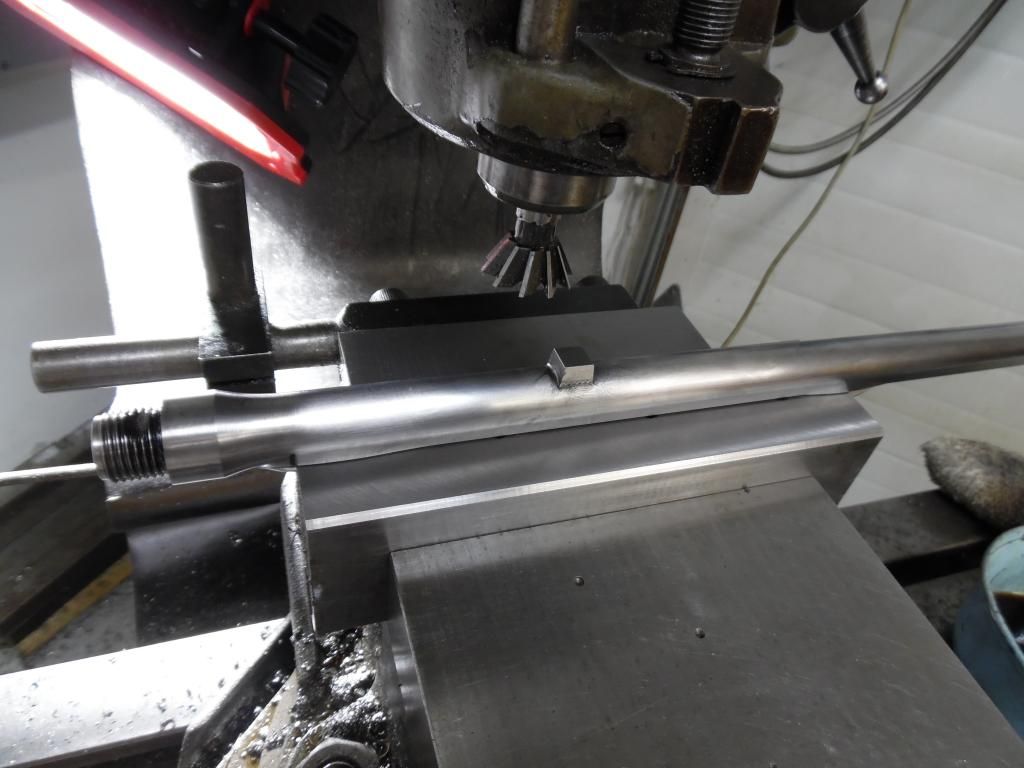

A holding fixture was needed and Morris used an old set of Kurt vise jaws. The jaws were first installed on the vise, surfaced, separated by spacer blocks and then dovetail cut on each face. This would provide a very precise method of holding the barrels in place by inverting the barrel and using the integral scope bases secured in the newly made fixture.

I didn't want to use a #10 drill for the wood because the fit with a #10 screw shank would be very tight and a small amount of draft was needed. I do some cabinet making also and found a 5mm wood bit in a drawer that was perfect for the job.

Each barrel was precisely positioned at the center of the forearm barrel lug and the sequence of drilling the lug, tapping it, installing the wood bit and setting the depth to the dead bottom of the lug (the top surface with the barrel inverted), placing the forearm in position and, finally, drilling the wood.

Morris sent #10 cap screws home with me for the final inletting of the forearms.

Dennis