The project is proceeding nicely. Here is a synopsis of problems solved.

Centerfire breach block

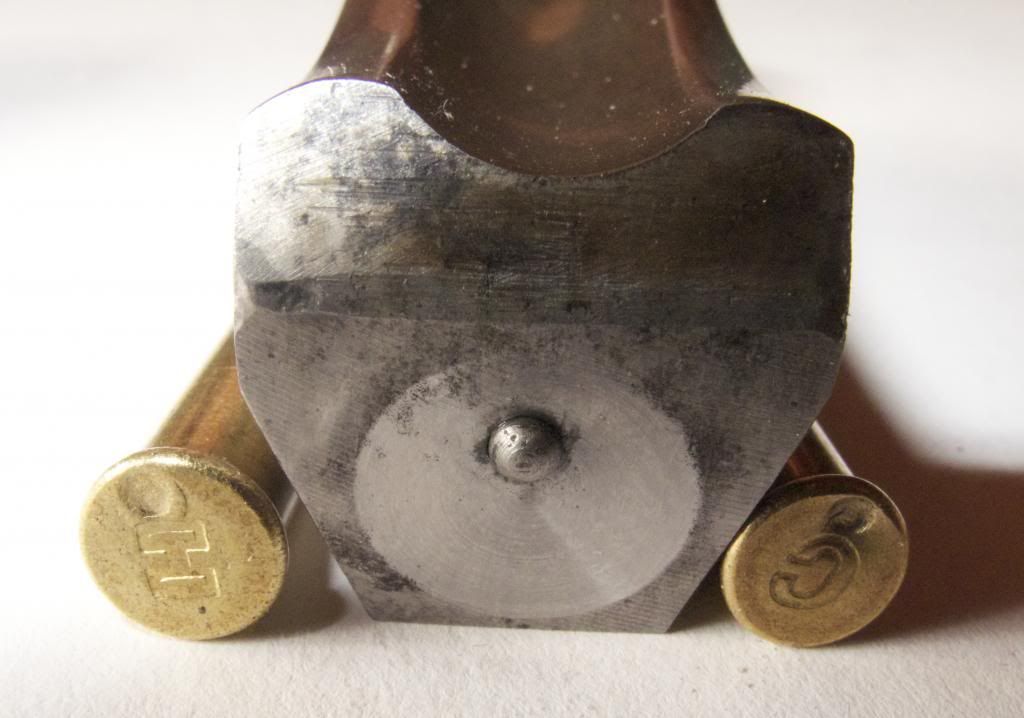

The striker nut retaining screw on the rimfire block had been broken off and had to be removed. I drilled the screw stub with a twist drill very near the minor diameter of the screw and then attempted to tap it with a 2-56 tap with the broken screw remnants in place. I broke the tap off in the hole and Morris had to burn the tap out using EDM. The threads were then carefully chased with a bottom 2-56 tap.

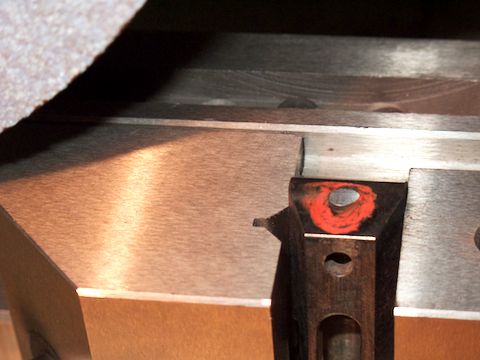

The first step in converting the rimfire block to centerfire was to thread the firing pin hole in the breach face with a 4-40 tap. A screw was turned in until it reached the bottom of the firing pin hole channel. The protruding part of the screw was then TIG welded around its juncture with the breach face. A surface grinder brought the weld level with the face.

The rimfire pin was ground from the striker.

The centerfire pin center was located on the breach face and drilled with a 1/16" twist drill through the face with the striker in place. This provided a secure location to solder a new firing pin in place in the striker.

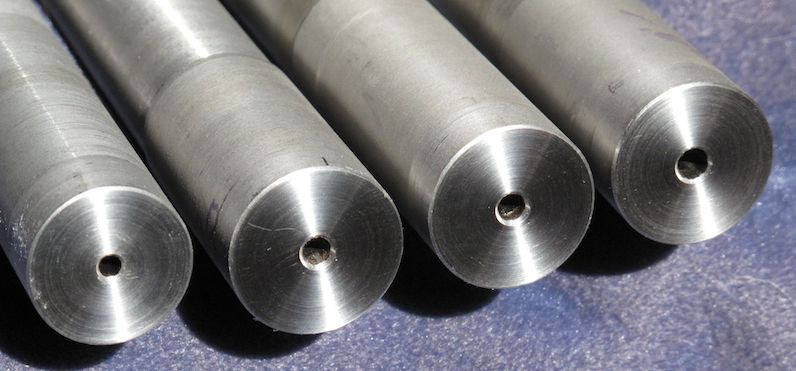

Morris turned the four barrel blanks round, established a precise common OAL for the barrel set, threaded and chambered each and then crowned them.

Each barrel was test fired to ensure primer detonation. Using a common rimfire block without making adjustment for the slight size difference in the .17 HMR and the .22LR didn't matter.

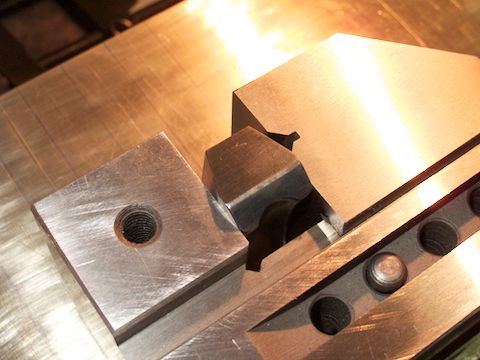

Martini lever movement has two positions. The first "nearly opened" position is maintained by striker spring tension. If the lever is pressed forward from this position the block under striker tension then allows the insertion or removal of a case from the chamber. The modified rimfire block would not lower sufficiently to allow the insertion and removal of the 5.6x50R or the .25-20 WCF rounds. The bottom of the block had to have metal removed to allow the block to drop further.

[img]http://i818.photobucket.com/albums/...0bd92.jpg[/img]

The next step will be to manufacture a common takedown taper pin that will work with all four barrels. Morris plans to create the taper cut on the thread bottom for each of the barrels with EDM. He has the fixtures designed, built and hardened that will hold each barrel while it is profiled on the HAAS CNC.

[img]http://i818.photobucket.com/albums/...25793.jpg[/img]