|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

|

Forums10

Topics38,547

Posts546,186

Members14,423

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Jan 2003

Posts: 803

Sidelock

|

Sidelock

Joined: Jan 2003

Posts: 803 |

I will find a copy of Marks.

-Dick

|

|

|

|

|

Joined: Jul 2005

Posts: 7,065

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 7,065 |

If we are just talking about the effects of casehardening or through hardening on a given double gun frame, no matter how high the hardness of the frame is raised, it won't change the amount of deflection of the frame when fired at all.

The stiffness of a gun frame will not change from hardness nor changing the steel from mild steel to chromoly, hard or soft.

The stiffness of steel is pretty much the same thru all the alloys and unchanged by hardness. But by increasing the yield point of the steel the frame can take more displacement without plastic bending. And since spring rates go up with some power(d squared or d to the power of 1.5 etc...) of displacement and a higher yield point receiver can take more displacement it's spring rate is higher right before plastic failure that a "soft" frame.

Last edited by AmarilloMike; 06/09/12 12:32 PM.

I am glad to be here.

|

|

|

|

|

Joined: Mar 2012

Posts: 347 Likes: 5

Sidelock

|

Sidelock

Joined: Mar 2012

Posts: 347 Likes: 5 |

This has been an interesting thread! Fertile grounds for a book on the metal types and treatments for double guns old and new by as many makers as possible. Would take someone far more savy than I!

Sam Welch

|

|

|

|

|

Joined: Feb 2009

Posts: 7,464 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,464 Likes: 212 |

Low carbon recivers were used because that was the extent of the Metalurgy at that time in history.

"Sudden fracture point is commonly known as Brittle Fracture and is a condition that a steel can be put into if not heat treated properly known as Martensite.

Recievers were annealed to remove the Martensite structure..

I believe, historically, medium and high carbon steel was well known and available in the late 1800's early 1900's. I think even today there's the use of medium carbon steels, but I believe there's a reason why high carbon steels are generally not used in receivers and barrels. I don't believe martensite is a heat treating problem. I think the whole point to the thread is the importance of case hardening, or the formation of martensite on the surface of steel that is unable to harden on its own. The thread is also asking if the hardness, martensite, were removed by annealing if the gun were ok to shoot. So, there seems to be an implication that we don't want to anneal the hard case of a receiver for possibly safety or durability reasons.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,880 Likes: 16

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,880 Likes: 16 |

Dick,

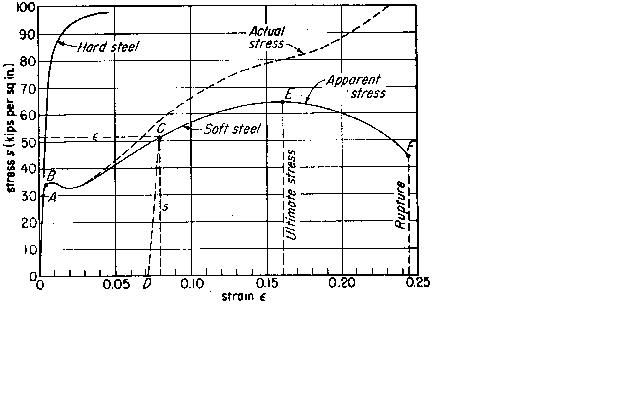

I'll defer to your explanation of MOE. Clearly, some of the folks here confuse MOE, ultimate tensile strength, and yield strength. I suppose a stress/strain diagram of two coupons, one hard, one soft would be helpful.

|

|

|

|

|

Joined: Feb 2009

Posts: 7,464 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,464 Likes: 212 |

....no matter how high the hardness of the frame is raised, it won't change the amount of deflection of the frame when fired at all...

Hi Chuck, this was the exact point I was awkwardly trying to make earlier. Would you be able to comment, and I'm interested to learn, if all is equal, will the hardened sample be able to deflect by a greater amount, before becoming inelastic, than the softer sample. I'm not thinking of force required as the samples approach their yield, but distance of deflection before first signs of permanent deformation. Again, purely to learn, don't mean to flog around on the ole dead horse.

|

|

|

|

|

Joined: Jul 2005

Posts: 7,065

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 7,065 |

I will find a copy of Marks.

-Dick Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978. Thanks, Mike

I am glad to be here.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,880 Likes: 16

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,880 Likes: 16 |

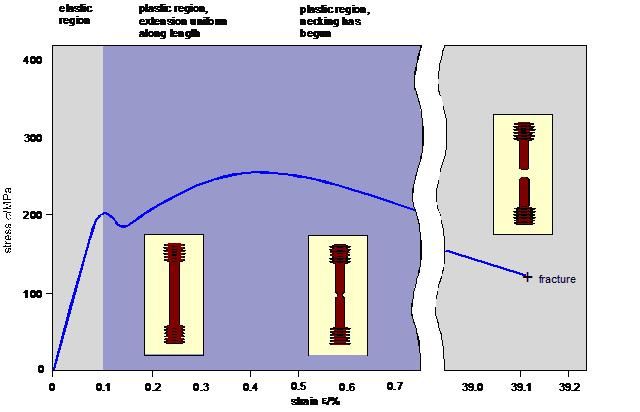

This first stress-strain diagram show mild steel.  This second diagram shows a hardened steel curve and a soft steel curve on the same diagram. You can see the stress and strain track exactly on top of each other (extreme left side of the diagram) until the soft steel starts to yield. The hard steel curve continues upward and you can see that it doesn't have much plastic region (more brittle). This is what you'd see in two identical flat springs, one soft and the other heat treated.

|

|

|

|

|

Joined: Jul 2005

Posts: 7,065

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 7,065 |

I will find a copy of Marks.

-Dick Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978. Thanks, Mike Dick when Chuck deferred to your expertise I got worried. I drove to my office. I am at my office looking at the "Standard Handbook for Mechanical Engineers". It doesn't say what I said it says.

I am glad to be here.

|

|

|

|

|

Joined: Jul 2005

Posts: 7,065

Sidelock

|

Sidelock

Joined: Jul 2005

Posts: 7,065 |

If I understand what I read this article says that carbo-nitriding low carbon steel raises signifigantly raises it's yield strength and tensile strength. I know we are talking about case hardening by carburizing http://resources.metapress.com/pdf-preview.axd?code=j5m0rm7q16833674&size=largestBest, Mike

Last edited by AmarilloMike; 06/09/12 04:49 PM.

I am glad to be here.

|

|

|

|

|