|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,467

Posts545,116

Members14,409

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Jun 2007

Posts: 313 Likes: 11

Sidelock

|

OP

Sidelock

Joined: Jun 2007

Posts: 313 Likes: 11 |

Ballistix's thread about his barrel problem got me concerned. Can any of you share what you would look for to determine if a bulge or dent had been repaired.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 313

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 313 |

|

|

|

|

|

Joined: Dec 2001

Posts: 6,993 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,993 Likes: 402 |

If a dent it properly removed it is very hard to see, next to impossible at times. As long as the barrel wall thickness has not been compromised, a dent is rarely an issue. Bulges are a very different matter, they are hard to remove and they have changed the characteristics of the metal once it has stretched beyond its elastic limit. If you can not see these issues with your naked eye, a bore micrometer helps a bunch. So does a bore scope, but they are usually quite expensive.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

A bulge almost always affects the area between the ribs as well. I doubt there are many repairs of bulges where the gunsmith strips the ribs off and does any cold forming of the area between the ribs. So, a bulge will likely show as a 'wave' in the bore in the area of the ribs. It will be a subtle change in the light reflection in the bore. It might be difficult to see, but should be visible. I've seen it even on subtle bulges.

I would not be overly concerned with small bulges, especially out in the thin section of the barrel past the forend. But a large bulge, especially as it gets in around the forend is a big concern to me and I would pass on a gun that had one or be thinking sleeving it when assessing whether or not to buy it.

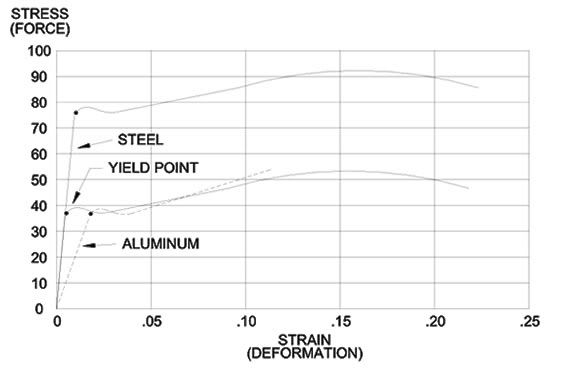

Any cold working of the steel affects the properties. Dents and bulges alike. For the most part, they probably do more to strengthen the area than reduce strength. A review of a typical stress/strain tensile test chart of a steel in the range of hardness of barrels would show you this. Just after the point at which the force required to yield (permanently deform) the coupon, the force required to yield it further is less. Then, the force required to yield it further goes up well beyond the original yield point. This is a result of "work hardening" the steel. As the grain structure is changed from the "work hardening", it becomes stronger until it finally fails. This is also why hammer forged barrels are very strong. Of course, "work hardening" can be over done and lead to earlier failure as well. Some of the barrel failures of the stainless Sako bolt guns may have been an example of this. For us with ole shotguns, I wouldn't worry about work hardening as a problem. Rather wall thickness and crack detection would be comforting to me. Your comfort requirements may vary.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

I found a typical low strength steel stress-strain chart. Note the dip in stress then the gradual increase in stress.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

BTW,

If the steel is work hardened too much, it can also be annealed to return it to a softer, more ductile condition.

|

|

|

|

|

Joined: Mar 2011

Posts: 2,982 Likes: 106

Sidelock

|

Sidelock

Joined: Mar 2011

Posts: 2,982 Likes: 106 |

So Chuck, what you are saying is that a bulge repair if done very precisely should be at least as strong as the original metal prior to the bulging incident? I'm not a physicist or an engineer and this is a little over my head. Also, where would a bulge lie on the stress deformation axis? Right at yield or could it be way far to the right?

Last edited by buzz; 07/28/11 04:55 PM.

Socialism is almost the worst.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

Buzz, I'm not sure I'd use the words "...done very precisely..." when describing beating on a piece of steel with a hammer.  But, yeah sorta. The main thing would be ensuring there were no cracks prior to attempting repair.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,879 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,879 Likes: 15 |

Any thinning of the steel from stretching does indeed reduce the capability, same as filing would. Which brings up filing as a way that someone may try to hide that last little bit of the bulge that won't seem to go away. If you see signs of a repaired bulge in the bore, I'd measure the wall at that point to determine how much thinning was done.

|

|

|

|

|

Joined: Mar 2011

Posts: 2,982 Likes: 106

Sidelock

|

Sidelock

Joined: Mar 2011

Posts: 2,982 Likes: 106 |

Interesting Chuck. I learn someting new on this great forum almost every day. But where does the bulge lie on the stress deformation axis, right at yield or could it be way to the right and how would you know?

Socialism is almost the worst.

|

|

|

|

|