|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,481

Posts545,233

Members14,410

| |

Most Online1,335

Apr 27th, 2024

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

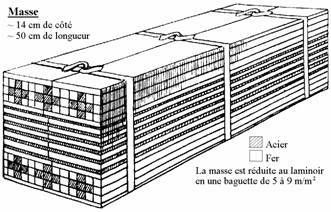

Finally made it to Sherman Bell's recent DGJ article. He certainly articulates the difficulty in defining Pattern Welded Shotgun Barrels, but his use of terms probably only adds to the confusion. As he mentioned, the technology and terms certainly changed between W. Greener's 1835 book and W. W.'s in 1910. At this point we're all a bit like Justice Potter Stewart trying to define porn in 1964, "I know it when I see it." Unfortunately, Bell did not discuss the THIRD form of Pattern Welded Shotgun Barrel - Laminated Steel. As has been discussed previously, Laminated Steel differs from Damascus Steel in that: 1. Laminated Steel has a higher steel : iron ratio, with higher quality steel. 2. Laminated Steel starts with the iron and steel mixed together (puddled) in a semi-molten state (the bloom) which is then hammered or rolled into rods. Damascus starts with individual strips of iron and steel. 3. Laminated Steel rods are twisted less than Damascus (but may have a pattern and the barrels are then referred to as "Laminated Damascus") No one source is adequate to define the 3 forms of Pattern Welded Shotgun Barrels, but this is probably the best from a mid- 19th century perspective: Engines Of War: or, Historical and Experimental Observations on Ancient And Modern Warlike Machines And Implements, Including the Manufacture of Guns, Gunpowder, and Swords with remarks on Bronze, Iron, Steel, &c.Henry Wilkinson, M.R.A.S. London 1841 p. 70 Part III On The Manufacture of Fire-Arms, And Modern Improvements. http://books.google.com/books?id=0XJeF_o...w3u60I#PPA70,M1 Starting on p. 87 Forging of Gun-Barrels A description of Stub, Stub-Twist, Wire-Twist, Damascus-twist, Stub-Damascus, Charcoal iron, Threepenny skelp iron, Two penny or Wednesbury skelp, and Sham-damn skelp. The most approved modern method of converting…(horse-shoe nails)…into ( Stub-Twist) gun-barrels after carefully sorting and picking the, to see that no cast-iron or impurities are mixed with them, is first to put about half a hundred weight into a large cast-iron drum or cylinder, crossed internally with iron bars, through the centre of which a shaft passes, which is connected by a strap with a steam-engine, and the revolution of the drum actually polishes the nails by their friction against each other; they are then sifted, by which every particle of dust is removed. The steel intended to be mixed with them is clipped by means of large shears, worked by the engine into small pieces, corresponding in size to the stubs, and afterwards cleansed by a similar process. About 40 lbs. are thrown on to the inclined hearth of an air-furnace, where they are puddled or mixed together with a long iron rod, and withdrawn in a mass called a bloom, almost in a state of fusion, to be welded under hammer of three tons weight, by which it is formed into a long square block: this being put in, at another door of the same air-furnace, is raised to a bright red heat, and drawn out under a tilt hammer of a ton and half weight, into bars of proper size to pass the rollers, by means of which it is reduced to rods of the required size. p. 95 Possibly a description of what was later termed Laminated Steel For the finest description of (Stub-Twist) barrels, a certain proportion of scrap steel, such as broken coach-springs, is cut into pieces and mixed with the iron by the operation called puddling, by which the steel loses a considerable portion of its carbon, and becomes converted to mild steel, uniting readily with the iron, and greatly increasing the variegation and beauty of the twist. In whatever manner the iron may be prepared, the operation of drawing it out into ribands for twisting is the same. This is effected by passing the bars, while red hot, between rollers until extended several yards in length, about half an inch wide, and varying in thickness according to whichever part of the barrel it may be intended to form: these ribands are cut into convenient lengths, each being sufficient to form one-third of a barrel: one of these pieces is made red hot and twisted into a spiral form, by placing on end in the prong of an iron rod, which passes through a frame, and is turned by a handle, the riband being prevented from going round without twisting by means of an iron bar placed parallel to the revolving rod. The spiral thus formed is raised to a welding heat, and dropped on to a cylindrical rod, which being struck forcibly on the ground (called jumping) the edges of the spiral unite, and the welding is then completed by hammering on the anvil. The other spirals are added according to the length of the barrel, and the forging is finished by hammering regularly all over. The ends of the spirals should be turned up and united at each junction of spirals, to avoid the confusion in the twist occasioned by merely dropping one spiral on anther; but this is rarely done. Wire-Twist, of any degree of fineness, may be obtained by welding alternate laminae of iron and steel, or iron of two qualities, together; the compound bar thus formed is drawn into ribands, and twisted in the same manner as the preceding. p. 96 The iron called Damascus, from it’s resemblance to the celebrated Oriental barrels and sword blades, is now manufactured in great perfection in this country, as well as in France and Germany, and may be varied in fineness or pattern to almost any extent, according to the various manipulations it may undergo. One method is to unite, by welding 25 bars of iron and mild steel alternately, each about 2 feet long, 2 inches wide, and ¼ of an inch thick; and having drawn the whole mass into a long bar, or rod, 3/8 of an inch square, it is then cut into proper lengths of from five to six feet; one of these pieces being made red hot is held firmly in a vice, or in a square hole, to prevent it from turning, while the other end is twisted by a brace, or by machinery, taking care that the turns are regular, and holding those parts which turn closer than others with a pair of tongs, the rod is by this means shortened to half it’s original length, and made quite round. If only two pieces are employed to form the riband, one is turned to the right, and the other to the left; these being laid parallel to each other are united by welding and then flattened; but if three square rods are used, the centre one is turned in a contrary direction to the outside ones, and this produces the handsomest figure. By these operations the alterations of iron and steel change places at every half revolution of the square rod composed of twenty-five laminae; the external layers winding round the interior ones, thus forming when flattened into a riband, irregular concentric ovals or circles. The fineness of the Damascus depends on the number and thickness of alterations; but when wound into spiral form, and united on its edges by jumping, the edges bend round and the figure is completed. If there is one thing that I hope to accomplish with my personal investment in time, money, and an increasingly limited intellectual reserve  , it would be to create a common language of Pattern Welded Shotgun Barrels so we can communicate effectively. Our illustrations and Pete M's movie shows the HOW of damascus production. The method of twisting and the arrangement of the iron and steel strips in the 'lopin' or 'billet' primarily determine the pattern that is produced however. My approach is to define those patterns, so we are at least talking about the same thing.

Last edited by revdocdrew; 07/31/08 10:38 AM.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Drew;

I do not have the DGJ, so cannot read Bell's take on this, but other than the inclusion of new patterns & also laminated steel, & the ommision of some patterns which had fallen by the wayside, I really see little difference between W & WW Greener's works of 1834 & 1910 pertaing to terminology of twist/damascus etc. From W Greener's 1834 work pertaining to the "Stub Twist" & "Stub Damascus" I do not get the impression the metal was brought to a melting (puddling) point but that the stubs & chopped coach springs were simply thoroughly mixed & brought to a "Welding Heat". At this point they would stick to an iron bar inserted into the pot & a large mass (bloom) would be withdrawn, put under the hammer thus completing the weld & forming into a bar. For Stub Damascus the mat'l was twisted in the bar, for Stub Twist it was not.

I do not know if is just an "EGO" thing or what, but while Bell has had some valuable info I have been somewhat turned off by his seeming insistance on "Tearing Down" everything early writers have said on various subjects. A prime example was the long shell/short chamber subject, which was fairly well settled just prior to & immediately following WWII & throughly reported on by Burrard. Bell took everything Burrard said totally out of context, made a complete wreck of all the work which had been done by the British Manufactures Which Burrard reported on & strongly Implied that no positive conclusions had been drawn until "He Did It".

In this case, as I see it, WW simply built upon the works W had started, I see nothing contradictory between them. Certainly time & experience had proved W Greener right in that steel was desirable (read that necessary) in the composition of a patterned bbl. W Greener had been emphatic about this in 1834 at a time when, according to him, some others made their bbls of all iron. In the ensuing years with the development of more powerful powder & heavier loads, many of those bbls discussed by W had simply proved inadequate & fallen aside. Also I believe that suitable "Stubs" had become mostly unavailable & so was virtually a thing of the past by WW's times.

By the same token the fact that oil, drained from the head of the Sperm Whale, is unavailable to us today does not mean that firms such as Parker, Lefever, Smith, etal were wrong in recommending it ca 1900 as the best obtainable for oiling their guns.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Feb 2006

Posts: 3,728 Likes: 50

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,728 Likes: 50 |

Drew,

I agree it would be nice to unitize the different kinds of Damascus along with the laminated and stub twist.

An example would be what old L.C. Smith catalogs referred to the different grades having good, fine and finest Damascus. We know that this same type of nomenclature was used by Parker and other leading gun companies, and I'm sure their Damascus grades were the same but probably with a different name.

So I have to agree that it would be nice to have a list of what they refer to and to have it universal.

David

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

To further confuse the issue... Whose definition of laminated? The English aka Greener? By the time WW wrote his book in 1910, he acknowledged that damascus was no longer being produced in England. There were multiple centers for damascus production, Belgium, France, Italy, Germany, Russia, Spain over this 100+ period. So what country and what time frame?

I see this as problematic for anyone who attempts to categorize, including Bell. While I have not seen / read his article, did he include any sources that were not English?

The production methods changed over this time span. As did the smelting.

Pete

|

|

|

|

|

Joined: Dec 2001

Posts: 2,399 Likes: 15

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 2,399 Likes: 15 |

I have seen two Ithaca Flues guns with one barrel twist, the other damascus. There is a picture of one of them in my book.

|

|

|

|

|

Joined: Jul 2009

Posts: 196

Sidelock

|

Sidelock

Joined: Jul 2009

Posts: 196 |

Drew/others Apologies for the basic query, but I noted this recent gun in the UK as having "skelp" barrels - the first time I had seen such a reference. http://www.byrnesauctioneers.co.uk/BidCa...tus=A&alot=Its apperance (albeit at a distance) appears quite mottled and not a regular pattern. Is skelp therefore a "lower" quality type of Damascus barrel? Forgive the ignorance - just interested to know. I am equally sure there are plenty of types of skelp - unfortunately have no further info.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

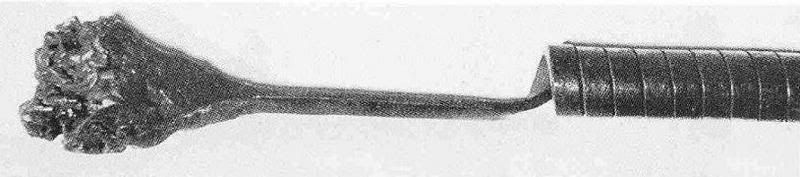

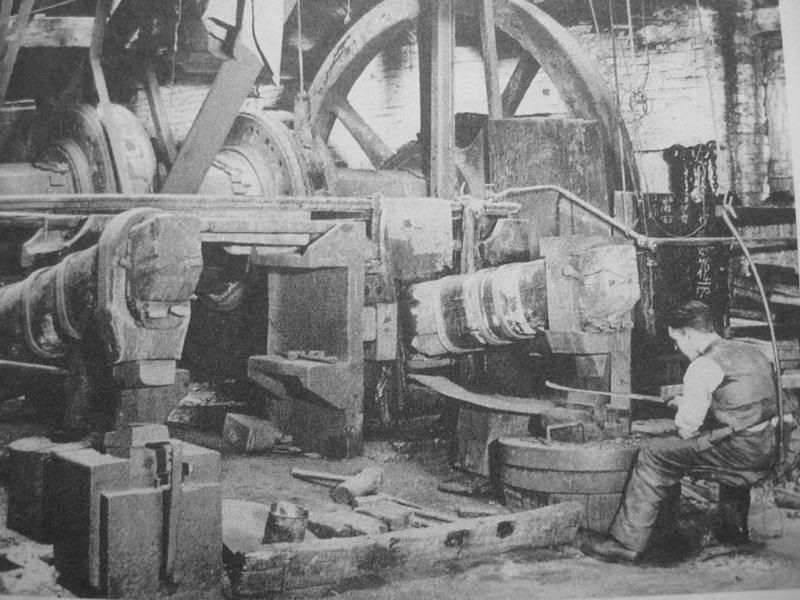

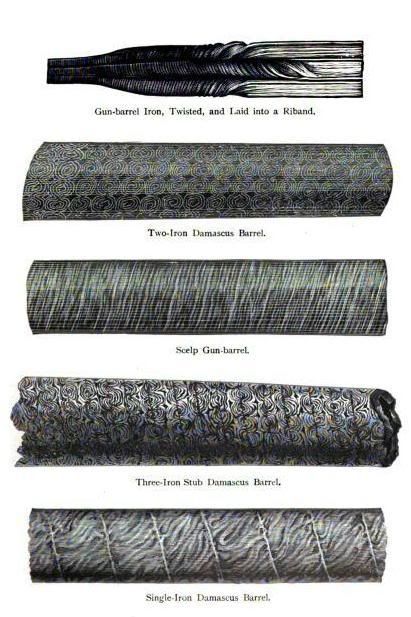

Well, you are asking a good question. The methods kept changing over time and by country / region. Pictures are the best way to illustrate the process. As written descriptions become confusing. Early on, some makers would incorporate used horse shoe nails along with cut up wagon springs, etc. This is basically known as skelp. Then they would twist these rods together to add strength. Eventually they would wrap them around a mandrel to form a barrel. The "patterns" were difficult to control at best. But the British in particular had the skill to produce rather consistent patterns using this method. The "other approach" was to have the pattern formed by alternating layers of iron and steel. Eventually, these rods were produced solely by rolling mills. The rods were purchased by the barrel makers according to the orders they had for various quality barrels. An early tool. The perrot used to twist the rods.  Belgian barrel makers with rods from the rolling mill.  A Belgian patent showing the layout of a rod that will produce a star damascus barrel.  Belgian makers forge welding the rods around a mandrel.  This is a barrel in process. You can see the chemise that protects the barrel from being welded to the mandrel.  Very early recreation a skelp barrel being formed.  Here you can see the skelp material. They would attach the horse shoe nails by welding them and then beating them into shape.  An English shop using a water driven trip hammer to form a barrel.  Some of the patterns from Greener's book.  I should add that these are very late methods, from about 1780 to 1930. The origins go back hundreds of years to Asia and India. There were early patterns produced in India that the European makers could never reproduce. Pete

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

By the time WW wrote his book in 1910, By 1910 Damascus was literally a thing of the past.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

In England damascus production had stopped. The Belgians continued into the 1930's.

In part, the huge WWI increase in steel production contributed to this. The steel industry needed to find other outlets for it's products and focused in part on sporting arms.

Smokeless powders really came into their own at this time, again a result of WWI.

Coupled with rising labor costs across Europe, this lead to the decline and eventual demise of damascus on a massed produced scale. The guilds had been on the wane for nearly 30 years.

In Belgium, some of the large arms makers turned their attention to the production of the automobile.

Pete

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Short version: English Twist was called "Plain Twist", "Birmingham", "Skelp/Scelp", and referred to as "Wire Twist" by W. Greener in 1835. This is Dr Gaddy's example  Long version Long version to follow

Last edited by Drew Hause; 02/17/10 10:09 AM.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

In England damascus production had stopped. The Belgians continued into the 1930's.

"Continued" making junk

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

OK-the dog's been jogged and Dr Beth's been walked and took to WalMart so here's the long version- even if only jOe is interested and it's WAAAY TMI  Skelp Skelp came from the 1350-1400 Middle English shelpen: to beat, flog, a slap, smack, or blow, esp. one given with the open hand. Crolle - Crull - Krul - Crullen - Curlen are also Middle English words that appears in Chaucer’s Canterbury Tales written c. 1386 “And his lokkes buth noght so crolle…” and a young Squier...with locks as "crulle as they were laid in presse." In Danish, krolle; Swedish, krulla; French, s'enrouler; German, rolle; Spanish, rollo. "To form into coils or ringlets. Twist." "Crolle" was used in reference to damascus barrels in Liege and England by at least the 1880s. c. 1800 the word Skelp (sometimes spelled scelp) was used in the pipe making process in reference to iron or steel rolled or forged into narrow strips and ready to be made into pipe or tubing by being bent and welded. http://www.madehow.com/Volume-5/Steel-Pipe.html In 1815, William Murdock invented a coal burning lamp system. To fit the entire city of London with these lights, Murdock joined together the barrels from discarded muskets. He used this continuous pipeline to transport the coal gas. When his lighting system proved successful a greater demand was created for long metal tubes. To produce enough tubes to meet this demand, a variety of inventors set to work on developing new pipe making processes. An early notable method for producing metal tubes quickly and inexpensively was patented by James Russell in 1824. In his method, tubes were created by joining together opposite edges of a flat iron strip. The metal was first heated until it was malleable. Using a drop hammer, the edges folded together and welded. The pipe was finished by passing it through a groove and rolling mill. Russell's method was not used long because in the next year, Comelius Whitehouse developed a better method for making metal tubes. This process, called the butt-weld process is the basis for our current pipe-making procedures. In his method, thin sheets of iron were heated and drawn through a cone-shaped opening. As the metal went through the opening, its edges curled up and created a pipe shape. The two ends were welded together to finish the pipe. The Gun, or a Treatise on the Various Descriptions of Small Fire-Arms William Greener 1835 http://books.google.com/books?id=oIEY4qL6_z0CGreener described 9 different gun barrels at that time, and in general was extremely critical of the quality of British gun barrels being produced: 1. Damascus from only two sources: Mr Clive of Birmingham and George Adams of Wednesbury (introduced about 1820) 2. Wire-Twist Iron ( later called Plain Twist or Skelp) 3. Stub-Twist Iron - Made from horse-nail stubs (iron) mixed with coach spring steel, fused ("puddled") into a "bloom of iron", then hammer forged into rods, rolled into threads but NOT twisted, which were then wrapped around a mandrel and hammer welded. He later describes Stub Damascus as Stub Twist rods which ARE twisted then hammer forged into a ribband. 4. Mr Wiswoulds Iron Barrels and a similar product called Silver Steel. These are described as ¾ steel and ¼ iron and from the description may be early Two Rod "Laminated Steel " 5. Charcoal Iron (without steel) – inferior to Stub-Twist 6. Threepenny Skelp Iron 7. Twopenny/Wednesbury Skelp8. Sham Damn Skelp which apparently was stained to look like Wire-Twist 9. Swaff Iron Forging made up from small scraps of lockplates and gunscrews The New American Cyclopaedia: A Popular Dictionary of General Knowledge George Ripley, Charles Anderson Dana 1859 http://books.google.com/books?id=kL9PAAAAMAAJ The commonest kinds of guns are tubes, formerly made by turning over a flat strip of iron called a skelp. about 3 feet long, 4 inches wide, somewhat thicker and broader at one end than the other, and lapping the 2 edges for welding. The skelps were forged and welded by hand, but this is now sometimes done by rolling, and the barrel is drawn out to its required length as it is welded in the rolls from an original cylinder about one foot long; or, as the most convenient way of obtaining greater thickness at one end than the other, two tubes are employed for each barrel, and the thinner is inserted into the thicker, one end of which is opened out for the purpose, and then the two are welded together. The quality of the barrel depends upon the toughness and elasticity of the iron; the former prevent; bursting, and the latter the bulging out of the iron by the explosive force of the powder. From a very early period the superiority of the metal used for horse-shoe nails was well understood, and the old nails, or stubs, were reserved for the manufacture of gun barrels. They were largely imported into England from the continent; and it was not until the supply was becoming insufficient that such success was attained in the use of other equally good materials is to render the stubs comparatively unimportant. Iron of unsurpassed quality was at last made expressly for gun barrels, and methods were adopted of using bars of steel in combination with others of iron, which together formed the mixture called laminated steel, now regarded as the very best material. Bars for iron barrels are prepared by the process of piling. The selected pieces or scraps are first clipped into bits of the size of stubs, then washed with water, and cleaned from rust with acid; they are next placed in a revolving drum and rolled until they become bright as silver, when they are piled and heated almost to fusion; the ball, weighing from 40 to 50 lbs., is hammered, and then drawn down t6 the required size in the rolls. The bars thus obtained may be used in a great variety of ways according to the kind of barrel to be made. They may be turned up longitudinally to form plain barrels, the grain of which runs lengthwise with the tube; or coiled in a spiral around an iron rod used as a core, and thus form when the whole is welded together the stub twist, the grain of which follows the spiral; or they may be piled up, 6 bars alternately with as many of steel, and the whole be then forged into one, and rolled into rods 3/8 of an inch wide, which coiled in a spiral produce the wire twist barrel; or into rods 3/8 of an inch square for being converted into Damascus iron. For this purpose each rod is twisted to the number of 14 turns to the inch, by which its thickness is doubled and its length reduced from 6 to 3 feet; three of these rods are then so laid together that the twists of the middle one run the contrary direction from those of the others, and the whole being heated are welded together and then rolled into a rod 11/16 of an inch wide for coiling in a spiral. It presents a beautiful appearance, resembling the Damascus blades, but is probably weakened by over twisting, and in England it is not esteemed so strong as the stub twist barrel. By slightly modifying the process a great variety of patterns may be produced in the figures. Appleton's Dictionary of Machines, Mechanics, Engine-work, and EngineeringBy D. Appleton and Company 1873 http://books.google.com/books?id=zi5VAAAAMAAJ Gun Barrels http://books.google.com/books?id=zi5VAAAAMAAJ&pg=PA936&dq=damascus+barrels&lr=#PPA935,M1 The barrel-making being also divided into several branches. The first process in the manufacture of musket or common barrels is the making what are technically called skelps. The skelp is a piece of iron about one foot long, but thicker and broader at one end than at the other; and the barrel of a musket is formed by forging out such pieces to the proper dimensions, and then folding or bending them round into a cylindrical form until the edges overlap, so that they can be welded together. It is then placed in a furnace, raised to a welding heat, and taken out, when a triblet or cylinder of iron being placed in it, it is passed quickly through a pair of rollers. The effect of this is, that the welding is performed at a single heating, and the remainder of the elongation necessary for bringing it to the length of a musket-barrel is performed in a similar manner, but at a lower temperature. This method of welding is far less injurious to the texture of the iron, which is now exposed only once, instead of three or four times to the welding heat. The Modern Sportsman's Gun and Rifle: Including Game and Wildfowl Guns, Sporting and Match Rifles, and Revolvers John Henry Walsh (Editor of The Field) 1882 http://books.google.com/books?id=OLwUAAAAYAAJCONSTRUCTION OF THE GUN http://books.google.com/books?id=OLwUAAAAYAAJ&printsec=titlepage&source=gbs_summary_r&cad=0#PPA83,M1 THE BARRELS Whatever may be the kind of gun about to be made, the first thing done is to forge the tube or tubes containing the charge. Formerly they were all made of plain iron, but for the last hundred years the barrels of all best guns have been constructed either of strips or twisted iron coiled spirally round a mandril, and welded together by heat, or of steel. At present the selection is from three kinds, viz., first, Damascus; second, laminated steel; and third, plain steel. Plain iron is only used for the very cheap guns intended for the foreign market, and I shall therefore only allude to it here in the most cursory manner. The other three kinds must, however, be more fully described. The chief difficulty in the present day is to obtain iron of sufficiently good quality to mix with the steel, whether for Damascus or laminated barrels. Formerly horseshoe stub nails were alone thought good enough; but of late years these have fallen off in quality, and are also insufficient for the supply of the increased demand for shot guns since the passing of the present game law. These stubs, generally mixed together with other "scraps," were welded together and forged into bars; but in the present day new iron is alone used, selecting the best quality in the market, and refining it by melting and puddling, after which it is submitted to the tilt hammer, by which its fibres are condensed and drawn out. Swedish steel is treated in a somewhat similar manner, and then the material is ready for the barrel forger, who proceeds as follows: Bars of equal length are laid together or "faggotted," and heated in a furnace, after which they are put under the tilt hammer, and hammered again and again, so as to condense the fibres, and weld the iron and steel together. The bars thus treated are cut into lengths, again "faggotted," and put in the furnace, when they are hammered into narrow strips of the desired width, as presently to be described. According to the kind of barrel intended is the proportion of steel and iron, and also the treatment of these metals by the barrel maker. Thus— In single iron Damascus the two metals are in nearly equal proportions. English steel Damascus is composed of six parts steel and four of iron. Silver steel Damascus has nearly eight parts steel and two or two and a half of iron. Laminated steel is composed, like English steel Damascus, of about six parts steel and four of iron. The sole difference in fact between steel Damascus and laminated steel consists in the manipulation of the rods, which are less twisted in the latter than in the former, but more hammered to produce firm welding and condensation of the fibres. Excessive hammering of Damascus iron interferes with the beauty of the figure. With the exception of plain steel barrels, all those for shot guns are welded by heat as above described, and wherever steel enters into their composition, wholly or in part, great care is necessary not to overheat them, as by that means its tenacity its materially reduced. The process of forging twisted barrels is as follows: A rod is first heated, and then twisted into a spiral form by means of two iron bars, one fixed, and the other held in a notch of a machine, which is turned by a winch handle, so as to effect the twist. These rods are then treated according to the quality of the barrels to be forged. Thus, for very common guns a single rod of iron is slightly twisted, and hammered when hot into a flat band. For the next kind two twisted rods of steel and iron are welded into a band. Successive qualities are formed of three, four, five, or six twists of alternate steel and iron, the most common being three and four twist. The next operation is similar in principle for all guns, though it varies in the degree of manipulation. It consists in twisting one of these bands, spirally round a mandril, as in the woodcut in which "four twist" but the appearance in the several twists differs only in the number of lines separating the rods of which the band is composed. When the rod is thus twisted it is allowed to cool, while others are twisted in the same way; and the next process is for the smith to join the edges by welding them under the hammer at a white heat, at the same time placing the twist with its mandril in a semi-circular groove, and turning it constantly under the hammer. When thoroughly welded a second portion is placed on the same mandril, and the two are heated together, after which, by "jumping" and hammering, they are welded into a continuous tube. By repeating this operation again and again the proper length is obtained, and the barrel is completed in the rough. Finally, light hammer-hardening completes the operation. In the process of forging the barrel forger commences at the breech end with thick bars, and gradually reduces the substance by selecting them of lesser dimensions. Plain barrels for the foreign market are forged by bending a flat ribbon of iron round a mandril without any twist, and then welding the edges together. Damascus barrels are of various kinds, those in most general use being as follows: 1. Single iron steel Damascus, made of a single twisted bar rolled out into a wide ribbon (seven-eighths of an inch wide), gradually reduced in thickness from the breech to muzzle. This is known as common twist, or skelp.2. Two-stripe steel Damascus, made from two twisted rods rolled into a ribbon five-eighths of an inch wide, and reduced in thickness as before. 8. Three-stripe steel Damascus, made with three twisted rods three-eighths of an inch wide, and also gradually reduced in thickness from breech to muzzle. 4. Fine Damascus barrels, chiefly made in Belgium, are made from four, five, or six rods by different makers. 5. Silver steel Damascus is made up of three or four rods with steel of a superior quality. These several qualities, as well as some others, are shown, in the annexed engraving, the drawings for which are from specimens of English (Marshall's) and foreign barrels shown by Messrs. Bland and Sons at the Sportsman's Exhibition, held at Islington in July, 1872.

Last edited by Drew Hause; 02/17/10 06:58 PM.

|

|

|

|

|

Joined: Jan 2002

Posts: 737 Likes: 23

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 737 Likes: 23 |

Joe-I don't remember if any of your beloved Scotts are damascus. If so, they may have Belgian made tubes. Think about that.

|

|

|

|

|

Joined: Jun 2002

Posts: 9,350

Sidelock

|

Sidelock

Joined: Jun 2002

Posts: 9,350 |

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Keep telling youself that...

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

Sorry to interrupt jOe's Belgian love fest  , and I've been searching without success for confirmation of this quotation from James Purdey II some time in the 1880s: " ... weight for weight (Whitworth) steel is stronger than iron and shoots harder, though not of so handsome an appearance as damascus barrels..." He preferred Belgian damascus "...not that when thorough sound English damascus can be obtained they are not superior, but because Belgian workmen are more careful than English, and there is thus less risk of slag and rubbish getting into the welds."

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

And let me take this opportunity once again to remind our British brethren that WE'RE STILL WAITING FOR THE ENGLISH DAMASCUS ROSETTA STONE!

|

|

|

|

|

Joined: Jul 2009

Posts: 196

Sidelock

|

Sidelock

Joined: Jul 2009

Posts: 196 |

Drew/Gents Is this barrel by chance English skelp?  and also here - on a different gun but by the same manufacturer;   Any thoughts appreciated.

Last edited by CBL1; 02/25/10 02:04 PM.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Looks like Laminated Steel to me...

|

|

|

|

|

Joined: Jan 2006

Posts: 9,417 Likes: 314

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,417 Likes: 314 |

CBL1: I believe jOe is correct, but could you send me high resolution full size images by jpg attachment to revdoc2@cox.net ? Lots of pics here http://www.picturetrail.com/sfx/album/view/18063717c. 1866 Joseph Manton Laminated Steel  William Greener 7b Pigeon gun c. 1844-1869 Laminated Steel refinished by Paul Stevens

|

|

|

|

|

Joined: Feb 2010

Posts: 1

Boxlock

|

Boxlock

Joined: Feb 2010

Posts: 1 |

Hellow Drew,

It has been some very good posts here.

Page 106-107,

Purdey the Definitive History by Donald Dallas

Quiller Press

Copywrite 2000

ISBN 1 899163 63 8

I was at Puredy and have a signed limited edition, which I just noticed...I'd not looked at that page.

The book I could afford, and only with the greatest will did I not drool all over the shotgun; as perfect as man and machine can make. Teh wood is so great and the polish so deep. To this day I can't tell what impreesed me the most, the engraving, or the wood.

To your question about Purdey saying during the 1880's, Whitworth compressed fluid steel was proportionately stronger than Damascus and consequently make lighter barrles. Boring of rifle barrles was also easier as the material was more even.

Purdey was the first gunmaker to use Whitworth's steel, according to Greener.

It was more expensive than Damascus, Purdey charged 2.10 pounds extra per gun. This was back when a pound was worth $5.00. It was stronger under strain than Damascus, harder, more durable and keeps it's brown better.

Whitworth barrels could be confused with cheaper steels and was always engraved Whitworth Fluid Compressed Steel.

At the turn of the century Whitworth steel was used less and less as ordinary steels was developed and accepted for gun barrels.

In the 1890's Purdey's used Krup steel as better than Whitworth's. How ever by early 1900's Purdey reverted back to Whitworth steel.

This is on page 106

|

|

|

|

|