After close to 30 years of entering the Maine moose lottery I finally drew a tag this year and that gave me an excuse to make the .35 Whelen I've wanted. I sent a good condition Remington M30 in 30.06 out to JES reboring and in less than two weeks he rebored and rechambered to .35 Whelen.

I did a break in procedure of shoot and clean for the first 10 shots and then 5 and clean twice using factory Remington 200g ammo. I then went to factory Remington 250g ammo and got excellent results (all at 100 yds).

I was ready to go but thought I would try a few shots with some factory Federal ammo that used 225 Trophy Bondeds. I touched off the first round, I got slammed, smoke from the breech, had to use a small brass hammer to get the bolt open, primer gone and the case head was a mess.

After that I went back to using the Remingtons and all was fine still shooting small tight groups.

When I got home I inspected the 20 fired Remington 250 cases and they looked good, measured within specs,

Neck diameter...unfired .380, fired .388

Behind shoulder .433 vs .442

Just above rim cut .463 vs .464

Rim .465 vs.465

OAL of case 2.484 vs 2.488

If anything, smaller than specs.......

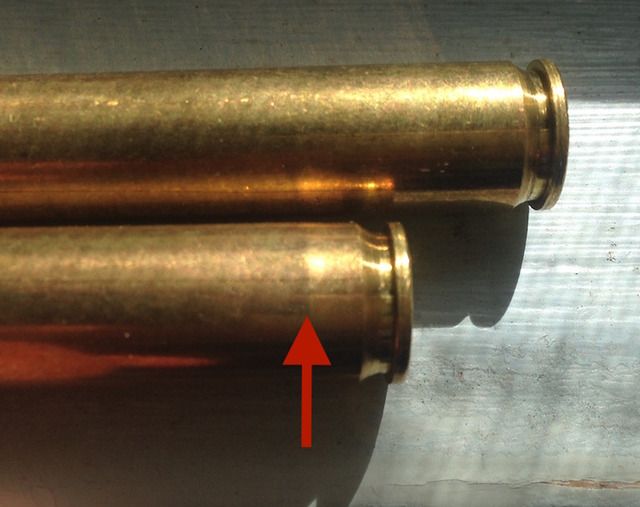

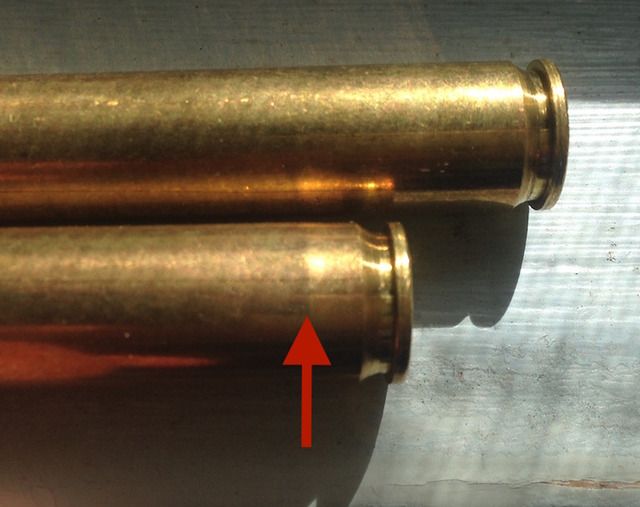

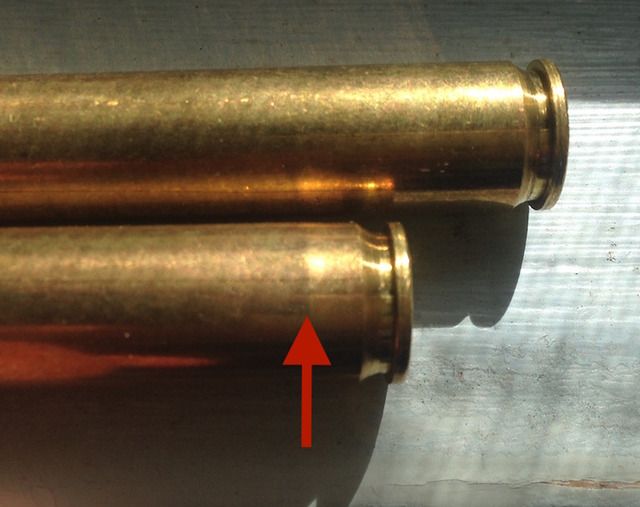

There's a mark on all the fired cases above the rim on the fired cases, it's diameter is .468 vs .464 on the unfired cases.

Some friends suggested it was probably a bad cartridge from Federal so I called them, they asked for photos, asked for the 3 boxes of ammo I still had. They tested them and wrote back...

"Examination of the P35WT1 that we received has shown that it met all Federal Cartridge Company and industry dimensional specifications.

We then fired the ammunition to test pressure and velocity and found that your ammunition had an average pressure of 51,143 psi and an average velocity of 2578 fps. The max pressure for this round is 58,000 psi and the average velocity of this round is 2600 fps. This ammunition fell within the specifications for this round. We were unable to duplicate the issue of a blown/ backed out primer that you original had. This leads us to the conclusion that this was an isolated incident and could be the result of a comparability issue between the ammunition and the firearm. If this happens again in the future we recommend having the firearm head space checked out by a certified gun smith."

They did send 4 boxes of new ammo to replace mine as a courtesy.

So I am still wondering what this could have been. The fired Remington cases showed no signs of stretching (though 1 had a split neck) and the specs on the fired cases seem to be within limits. I have not checked the headspace and will do so but it seems that it would be OK from the fired case dimensions.

Any ideas?

At least it didn't affect my hunt, taken Tuesday, 10/11 at 5pm using the 250g Remington stuff, 742 lbs dressed, 41"....

thanks,

Rob

Congrats on the Moose!

I believe you need to have the headspace measured. I don't think there is an issue but you need to checkmark the question on the list of possibilities to put it to bed.

Hope you can keep us informed as you resolve the issue.

Nice moose!

heck dump the Federals and stick with the Rems.

That is not a case that was only suffering from excess headspace. Only extremely high pressure does that to a primer pocket and molds the case head into the extractor slot. If the rifle has excess headspace now it may well be from bolt setback from firing that cartridge.

Congrats!

Great moose, great story and I'm glad that you and the rifle survived the blown case! I can offer no opinion except to say I''d be gun=shy of the Federal (usually preferred) ammo.

Who, what and where is JES reboring?

Thank you for the input gentlemen. I am going to have to get a hold of some Go/No Go gauges to check the headpsace, I hope that one round of Federal didn't set the lugs back. Fired Remington cases after the incident measure correctly so maybe I got lucky. I certainly don't want to have to mess around with it now that it's shooting so well. And yes, I am reticent to use any of the four boxes they are sending me.

Steve, JES reboring is

http://www.35caliber.com/, the Ocumpaugh brothers, Jesse and Wyatt. I did some research on reboring and they seemed to get good reviews.

I sent them the gun, they had it in their possession for 10 days before returning it, they charged $225 for the service

including return shipping, and the gun shoots way better than I deserve to shoot it. They don't do email but do return phone calls. I have nothing but praise for them.

They sent the gun directly to our own bpgunsmith, Brian Perazone who drilled and tapped for the one piece Buehler mount.

I didn't realize the Buehler would be so long. I was planning on a modern Zeiss fixed 4X but it was 1/4" too short between the bells. I have about 25 scopes and only one fit, an old steel bodied Weaver 3x9. It was picky about eye relief and I surely needed a brighter scope at 5:30pm in the North Maine Woods. Luckily the shot was under 100yds, 3X was fine and I had plenty of time to take the shot. But I'm going to find a modern scope with 6" of straight tube to mount, maybe a Leupold 3X or a Burris Fullfield.

Scope problems aside I wanted to take the moose with a classic weapon and while the M30 isn't as pretty as the 1903's we see around here I sort of like them, especially the safety. My back up gun was Sav. 99 in .358 so I was committed...

Great sets of pictures, and thanks for the write up. It looks like JES does a top job at a modest price. I would proceed cautiously, but with all the measuring that you have done and might keep doing, I'd skip the gauges and use the Feds, since they're coming anyway. It looks like the action did a good job of handling the odds and ends that came back, glad all is well.

I don't have a theory about your pressure problems, but I do have a similar experience. Nearly twenty years ago, a good friend built a 35 Whelen on a Mauser action. The rifle gave good performance with handloads, but Mike was not a reloader. When he tried Federal Premium ammo, he got the same results you did. Unfortunately, he didn't follow through with Federal to determine what the problem was with their ammo. I can't imagine why Remington ammo would be OK and Federal not unless something is seriously wrong with the latter.

I agree with WJL, excessive pressure was the culprit. The question is "what caused the excess pressure"? Excess headspace does not do that. It could be a double load in one cartridge( or excess load less than double), which may not have occurred in the other cartridges. I believe you will never know, for sure, what caused it. If it were mine, I would just either shoot Rem. or my handloads using Rem. brass.

Mike

That's the plan Mike, I'll shoot the Remington I have left and then develop my own load.

thanks,

Rob

Is it possible that the Federal case neck was long enough to protrude into the forcing cone, squeezing and holding the bullet long enough so that excess pressure was produced before it was released?

How about the bullet being jammed into the forcing cone as the round was chambered,once again producing excess pressure on firing?

Measurements of the new Federal cases and bullets might be interesting, but might not show the same dimensions as the "problem" round.

The only other possibility that comes to mind is too much powder, or the wrong type.

Someone on the Accurate Reloading forum thought the throat might be too short and suggested checking it with a bullet seated base first?

Either the throat too short, the case neck too long, or a bullet profile not compatible with the throat sounds like the most likely cause to me.

A quick test with the new Federal ammo would be to simply chamber the rounds, note any unusual force needed to do so or close the bolt, and finally, note the effort needed to extract the un-fired rounds.

Will test and report back when the new rounds arrive.

The Remingtons were 250gr. round nose soft points, the Federals were 225gr. Trophy bondeds which are spitzers.

thanks,

Rob

vangulil,

Usually, if I'm checking for some interference, I find it easier to "smoke" the neck/bullet with a lighter or candle. This gives a better view of the areas of interference.

Mike

vangulil,

Usually, if I'm checking for some interference, I find it easier to "smoke" the neck/bullet with a lighter or candle. This gives a better view of the areas of interference.

Mike

Sounds like an excellent idea. I have a situation myself where it should prove helpful.

Highly recommended for the OP.

you can "smoke" a case with a Sharpie or Dry Erase marker if you don't have a candle.

you can "smoke" a case with a Sharpie or Dry Erase marker if you don't have a candle.

Thanks for the suggestion.

I'd also consider checking the Rem's. I'd struggle with the confidence if I were to stick another Federal in, but chances are, the blow up was a one off. I'd think the replacement cartridges would be in spec.

Early on, there was a mention of a neck split on the good ones. Maybe take a careful look at the other necks and make reloading adjustments if needed. Just thoughts.

Yes, one of the 40 Remington factory loads had a split neck.

Would a chamber cast be of any use?

I would not expect bullet seating depth to have that much effect on chamber pressures. Bullet depth and crimp can indeed increase pressures a bit, but unless the loads are reaching maximum spec for the cartridge, it wont have that result.

I'd be getting out my bullet puller and pulling one cartridge apart on both the Federal and the Remington, and do a visual examination of the powder, plus measure the charges for both, just as a comparison. If it was an isolated incident, then an over charge wont show in an inspection, but I'd still do it to answer my own curiosity. By reverse engineering the charge based on weight, and info Federal provided on fps of their ammo, you might see something that you wont know without dissecting the components.

....Would a chamber cast be of any use?

It's just a thought, but if you're satisfied that there are no unusual pressure signs, I don't know if a cast would tell much more than the fired cases already do. If it were me, I'd try not to push the shoulder back much when sizing, but it has the look like the neck is going to get worked a good bit. Maybe it wouldn't be too bad a thought to anneal the neck area and watch case lengths a bit more than average reloading.

I have had great results from JES. I had a bad barrel on a martini cadet someone screwed up befor JES got a hold of it .. When I discovered the problem and was sure it was not his fault I found another barrel (luckily) and sent the gun to him with a check for the new work. He did the new barrel in .357 maximum as I wanted and the chambered the barrel with the bad chamber in 35 herrett for no charge. An honest, fast turnaround craftsman

Jerry

Some more info for anyone interested...

I had posted this over on the Accurate Reloading forums and from there was made aware of a member having similar pressure problems with a .35 Whelen, rebored by JES in 3 groove, 1-14 twist like mine. JES states his .35 rebores are .349 bore, .359 groove.

Someone suggested it might be a tight bore so I slugged mine and came out with the quick sketch you see below. Notice it's not drawn to scale and I was able to get a caliper reading across a land and a groove.

It's 3 groove rifling so each land has a groove opposite, each taking up about 60 degrees of the circumference. I was able to measure the slug at 3 locations, all came out to .349.

Am I correct that to get the groove diameter (which should equal bullet diameter) I would add .004 (assuming average groove depth of .005) and arrive with .354?

This is .005 less than bullet diameter of .358.

I measured the Federal bullets and they are indeed .358. Interestingly enough the Remington Corelokts measure .356.

I am waiting on a call back from JES to see if I have made a mistake, the idea of 3 groove, not having lands or grooves opposite each other, is a bit perplexing.

Interested to hear thoughts from this community.

N.B. I just spoke with Jesse at JES, he told me my method of measuring is incorrect. he starts with a .349 hole and then rifles .005 deep for a groove depth of .359.

He thinks it may have been the Federal ammo and is going to get some to test.

thanks,

Rob

....(assuming average groove depth of .004)....

Can you measure this instead, and then do the math? I think an odd number of grooves is perfectly fine.

N.B. I just spoke with Jesse at JES, he told me my method of measuring is incorrect. He starts with a .349 hole and then rifles .005 deep for a groove depth of .359.

He thinks it may have been the Federal ammo and is going to get some to test.

Then, I'd suppose you should be measuring .354" instead of .349" using your method? Since, JES is responding and looking in to it, maybe see if they would like you to mail them a slug? They would probably rather do their own slug, but it may give them ideas.

That's what I thought, I should be measuring .354.

JES is not going any further with it but to check the ammo.

Perhaps I don't understand the geometry involved but I'll pursue it further though and report back any findings.l

With three grooves, they should be 120 degrees apart. If the bore is 0.349, measuring as you show, between the center of the bottom of a groove and the land directly opposite it, should give 0.354, not 0.349, for a 0.005 deep groove. The measurement would have to be from one land to another to give 0.349. If the grooves each do not span more than 60 degrees, there will be locations, 90 degrees or so from the centers of the grooves, where lands will directly face each other. Measuring from one land to another here would give your measurement of 0.349.

With care in choosing your locations, you should be able to both measure from land to land and from bottom of groove to land.

This is exactly what I thought. The grooves and lands are each 60 degrees of the circumference so I am able to get an accurate reading across all three sets, .349.

If the lands and grooves both span 60 degrees, almost all measurements should be between the bottom of a groove and a land. These measurements should be 0.354, not 0.349.

You would have to measure almost exactly from the extreme edges of two opposite lands to get 0.349 with a bore of 0.349.

Moving slowly around the circumference, you should almost always get 0.354

This is the point I have been trying to make, I should get .354, I am getting .349.

The way to measure a "slug" from a barrel with an uneven number of grooves, is with a special "V anvil" micrometer or with a special "V block"( special for the number of grooves) and common micrometer. You can get a pretty good approximation by measuring with a dial or digital caliper and carefully "rolling" the "slug" until it slips past the jaw of the caliper; or wrap the "slug" with a piece of thin shim stock or a thin blade of a "feeler" gauge, measure it, then subtract twice the thickness of the shim stock.

Mike

Mike, I can see where that might be necessary if there is a considerable difference in the width of lands and grooves but on my slug they are they same size, there's no trouble using a dial caliper. The 60 deg. arc is plenty to insure you can touch the lands on the slug.

Recoil Rob,

I think you should add twice the .005 to the .349". This will give you .359" It is hard to "see", but .005 taken from the radius, would be .010" from the diameter. It is the same as "turning" something on a lathe- a .005" cut reduces the diameter .010"; in other words .005" off each side. A simple test would be to insert a bullet into the neck of a fired case. Whichever diameter bullet that will easily enter, can be used, even if a little over groove diameter. As long as the neck has room to expand/release the bullet( normal cup and core-not solid)a slightly oversized bullet doesn't excessively drive the pressure up. Once the parallel part of the bullet has traveled it's own length in the barrel, it has been sized to the groove diameter. This occurs while the pressure is rising.

Mike

Mike,

Here's some better diagrams below of the slug I made of my barrel (the drawing's from the other guy that has the same problem) I have measured from across one land to the depth of one groove and arrived at .349.

Add another groove depth and we're at .354. You wouldn't want to add a third groove depth.

If the groove depth is .005 that means the bore is actually .344 and the groove diameter is .359.

The other thread shows a burst a fair bit down the bore, is the fellow sure nothing was in there.

I still think, it may not be quite right to assume a .005" groove depth. I was probably seeing it wrong, but a fellow on the thread was demonstrating how to mic a bore slug. It looked like he had a picture of a 60* anvil. I think the right one for a three groove slug would be a 120* anvil on a calibrated micrometer.

It could be that a three groove barrel with wide lands like your drawing shows, could displace quite a bit more bullet metal and push up pressures some for the same groove diameter, maybe. I don't know though, that burst has the look like something was in there.

Recoil Rob,

You are measuring groove to land, measure groove to groove.

Mike

Mike,

With 3 groove, grooves opposite lands, you cannot measure groove to groove. We measure groove to land and then added in the one groove depth to get groove diameter, or, subtract one groove depth to get bore diameter.

Rob

RecoilRob,

That is why I said above, the proper way to measure the "slug" is with a "V" anvil micrometer or specially made "V" block and normal micrometer. The other methods I mentioned are approximations. The high points on the "slug" represent the grooves in the barrel You can measure the "bore" diameter directly, with a "small hole gauge" and a normal micrometer.

Mike

I understand that Mike but I have the slug in hand, I am confident the measurements are correct and my math is correct, I don't feel the need to go any further, in my opinion, the bore is tight.

If you have such a tool can I mail you a slug so you can confirm or refute?

Actually, even a small hole gage is problematic in measuring bore size. The best method is with a series of pin or plug gages. I believe this was mentioned in the AR thread. That will give a true reading of bore dimensions.

Unfortunately, JES has not responded to either of these threads. His input is very important. I find it difficult to believe that only these two rifles have undersized bores since, it can be assumed all are done with the same tooling.

The guy on AR doesn't seem to grasp that a slug will only record the smallest spot in the barrel.

The guy on AR doesn't seem to grasp that a slug will only record the smallest spot in the barrel.

Is not the "small spot" the fly in the ointment?

I'll push a slug all the way through the bore to feel if I can tell how uneven a bore is, but I admit I doubt I'm much good at picking up small differences. The only bore I worry about slugging is just past the throat, then push it back out the way it came in.

A good rifle barrel can have some choke in it, sort of like a shotgun barrel, and I believe it's a mistake to judge a barrel or choose a bullet based on what could be a little tight spot at the muzzle. It's very possible that a good cut rifler is aware of that, particularly since a prefinished barrel can't be shortened to clean up a bad muzzle.

Some barrels just don't shoot well, but that doesn't seem to be the problem here.

RecoilRob,

If your mind is made up, I can't change it. I do have a "V" block, but I made it for 5 groove barrels, 3 groove takes a different included angle. If a .358" bullet will easily enter the neck of a case fired in the rifle, then .358" bullets can be used w/o problems. BTW, my small hole gauges are round on the end, I wasn't talking about telescoping gauges, which are used on larger holes.

Mike

I was referring to small hole gages, not telescoping gages. They are round, but smaller than the diameter being measured and still end up measuring point to point, making it difficult to get an accurate measurement. You can use feel to get an average reading by rotating as you open them, but it is difficult to get a true reading.

JC,

Pin gauges can also be misused. If they are not presented precisely "square" to the bore the mechanic may think that one that actually fits is too large. The old German proofs used them to determine bore diameter, with their gauges being in .01mm steps. A barrel then marked 7.7, might be 7.71 or it might be 7.79 and still not accept a 7.8 gauge. Or it might be 7.8, if the gauge was not properly presented, at first.

Mike

Mike,

My mind isn't made up but I don't think we're on the same page.

What does a 0.358 bullet entering the neck of a fired case have to do with a tight bore?

Rob

RecoilRob,

If your mind is made up, I can't change it. I do have a "V" block, but I made it for 5 groove barrels, 3 groove takes a different included angle. If a .358" bullet will easily enter the neck of a case fired in the rifle, then .358" bullets can be used w/o problems. BTW, my small hole gauges are round on the end, I wasn't talking about telescoping gauges, which are used on larger holes.

Mike

In the USA, max pressure of the 8x57 is held to a lower standard (by SAAMI). This is done as early J bored had a .318" bore. If you fire a .323"JS bullet, it will swage down to the smaller bore, but 99.99% of the time no damage will occur.

In the blown rifle, the bullet was still in the barrel. That just doesn't happen. 100,000+psi (enough to blow up a barrel) means that bullet isn't going to stop. No way, no how.

He can claim the barrel was clear, but IMO, that barrel had an obstruction.

I assume you mean 0.1mm steps, in which case, the best that can be said about a bore which will accept a 7.7mm pin and not a 7.8 mm is that the bore is larger than 7.7mm and smaller than 7.8mm. Use of any gage assumes that the operator is skilled enough to use it properly.

Standard pin gages are 2" in length, to use properly up to the full length of the pin should enter the bore. This precludes installing it at an angle. Standard pin gages are furnisheed in master sets with pins in 0.001" increments, permitting measurement to +- 0.001". If this is not sufficient for the application, individual pin gages can be purchased in 0.0001" increments. Ideally, for measuring a bore, a set of gages on either side of optimum would be purchased to determine the actual bore diameter.

Pin gauges, .0001 tolerances, "precisely square to the bore"...

What happen to slugging the barrel with lead?

This week I'm going over to a buddy with a lathe and we're going to turn a .349 pin, if as the reborer stated he does his Whelens with a .349 bore it should fit, if it doesn't we'll try a .348, .347, etc.

Will report back, shouldn't be hard to tell which it's closer to, the .349 claimed or the .344 I measured with lead.

It would be much simpler to find someone with a proper set of pin or plug gages. They are a common item in many machine shops. If you were located near me, I would be happy to help.

Thanks for the offer, this being the heart of blue state territory not a lot of machine shops.

RecoilRob,

It doesn't have that much to do with a tight bore. What it shows is that the case is expanding enough to release the bullet, rather than restricting it, thereby driving the pressures up. If the bullet is not restricted from starting to move, a slightly larger bullet will not unduly raise pressures. On the otherhand, if something restricts it, such as case neck/bullet diameter too large for chamber neck or too long case jammed into leade, pressure must rise enough to overcome the resistance before the bullet can move. This results in a higher peak pressure. If the bullet is able to move without undue restriction, before entering the barrel, the volume of burning gasses is increasing which moderates the increasing pressures. By the time the pressures peak, the bullet has been sized to what ever the barrel diameter will allow. This occurs by the time the bullet travels the length of it's shank into the barrel. This description of what happens may not be precise, but is how I understand it. This is not something I discovered, it comes( as I understand it)from experiments done while developing the German 8x57 IS cartridge from the 8x57I; before WW1.

Mike

RecoilRob,

What it shows is that the case is expanding enough to release the bullet, rather than restricting it, thereby driving the pressures up. If the bullet is not restricted from starting to move, a slightly larger bullet will not unduly raise pressures. On the otherhand, if something restricts it, such as case neck/bullet diameter too large for chamber neck or too long case jammed into leade, pressure must rise enough to overcome the resistance before the bullet can move. This results in a higher peak pressure.

Mike

Agree.

While the investigation into bore diameter should continue, a chamber cast would also be a very good idea.

I asked about that early on and was told not necessary since I have the specs on a fired case.

JC,

I did mean 0.1mm steps. A correctly sized pin will only enter the bore if it is properly presented and this does depend on the skill of the mechanic. So does the proper use of small hole gage depend on the skill of the mechanic. There are a great many more small bore gage sets around than pin gage sets, and they are considerably cheaper. Furthermore, one set of small bore gages will cover all the more common barrel bores, but it would take two pin gage sets to span the diameters. You would need a precise measuring instrument to use small bore gages, whereas the pins themselves are the instruments. On the other hand, we all need a precise measuring instrument anyway, so that is not really an extra requirement. Pin gages come in .001" steps, but common micrometers read to .0001" on the Vernier. I guess what it boils down to is we just use the best tool we have, the best way we can.

Mike

Recoil Rob,

It is never a mistake to make a chambercast. You can get good diameter measurements, but length measurements are harder. A chambercast from a bolt action rifle doesn't have a precise point to represent the case head.

Mike

As promised....

This afternoon I took my barreled action over to a friend with a small shop and we turned some .500 brass round stock.

We started by turning a brass pilot to .349 and it would not fit into the muzzle. We decreased it in .001 increments, .348 no go, .347 no go, it would only fit into the muzzle at .346. We then cut off the plug and cleaned the ends to see if it would slide through the bore, it did not. The bore got tight about 5 inches back from the muzzle and I had to tap it though the rest of the way. This tells me the bore is not .349 but more likely .344-.345.

This also tells me I was correct in how to measure a slug of this type of 3 groove barrel, where you can get a caliper to measure across a groove and land, then add 1 groove depth for groove diameter or subtract 1 groove depth for bore.

Since JES advertised his .35 calibers as .349 bore and .359 groove, I gave him a call. He was still a bit reticent to listen, he told me that he had obtained some of the Federal ammo I used and thought that his chamber reamer produced a throat that was too tight for this modern ammo. He told me how the rifling process can leave sharp edges on the lands which can make the bore seem smaller but that will wear away in a few rounds. When I told him I had put about 60 rounds through the gun he agreed it was a non-issue.

In the end I told him all I ask was that he redo the process again so that it measures the stated .349/.359 and he said he'd be happy to do that. At the same time he's going to rechamber with the new reamer to ease up the throat dimension and, at my request, also check the headspace to make sure the pressure spike didn't set back the lugs, though he highly doubts it did. I just hope it's as accurate.

The gun is off to him tomorrow, when it comes back with the correct .349/.359 I'll consider the matter closed and am on my own with it from here on in.

All in all, a learning experience, didn't lose any fingers and have a freezer full of moose.

RecoilRob

Let us know how it works out.

Mike

I will Mike, thanks to all for their suggestions and enjoy your day tomorrow.

Rob