Was looking for source, any recommendations?

Garage sales, Pawn Shops, etc. Look for good steel and grind to fit. Old Stanley screw drivers are excellent steel.

I thought about grinding a few myself, now would parallel drivers be the same as hollow ground?

Parallel ground is not exactly the same thing as hollow ground. But, they both accomplish the same thing............having a blade that doesn't try to lift out of the slot under torque.

SRH

Fixed blade turnscrews are great to have and look nice in a case along with the gun but unless you have a surface grinder to grind them perfectly, you will ruin more with a 6" or 8" grinding wheel and never get the tip parallel.

If you are going to do a lot of screw turning the Wheeler set is hard to beat as they have many tips that fit most of the American guns made.

These caught my eye

https://www.garrettwade.com/gunsmith-screwdriver-set.htmlI can probably make these, hand filing would be the way to go.

I've got a set of eight wooden handled, fixed blade ones, in my shop, and a set of Brownell's with interchangeable tips. Ninety nine percent of the time, when doing gun work, I use the Brownell's set. It's just so much easier to get a perfect fit with the screw slot.

The GW set looks very nice, and I could see grinding a set for a particular gun and including them in the case with it.

SRH

What David Williamson said about hand grinding bits to fit is true. But you can do a very good job of keeping the sides parallel if you use a small diameter stone in a drill press, and hold the shank in a small vise that isn't locked to the table. Moving the table up and down keeps the wear on the stone even.

SKB is right about the steel in the older Stanley screwdrivers being very good. Old Craftsman screwdrivers are good for regrinding too. I have a set of hollow ground fixed Bonanza Gunsmith Screwdrivers, but have repurposed many common screwdrivers by regrinding. You have to be careful though, not just to grind them correctly, but to get good steel. It is easy to discover the steel is too brittle by breaking a bit and marring a screw head.

Stan and David are right about the convenience of the Brownells and Wheeler sets with interchangeable bits. I do find that the Wheeler bits are a tad more brittle than the Brownell's bits though.

I know a great many people love and use the interchangeable tip screwdriver sets.I personally just don't care for them. Constantly changing the tips is an annoying little thing and I don't own any such tools other than some socket wrench sets. But those rarely get a workout on a Parker.

Anyway, I have always just ground and reground the tips & width as I needed them. Mine are all lying in a pile on the benches or generally stuck blade down in a coffee can.

No fancy wooden hangers above the bench. You get to know them by each of their unique handles as they've all come from different places and eras.

Shaping is quick to do and easy. I've found a bench grinder the least favorable tool to use to grind and shape them. It is slow and overheats them easily. Plus I can't see what I'm doing working with one very well.

I use a belt grinder (4x36) and work/grind off of the bottom wheel.

Using a very coarse belt to start with,, A 120 works well to take a large bit down but 220 is usually where I start and finish.

The shaping is fast and the work runs cool (so to speak) with little chance of overheating the blade. A can of water sits nearby for a dunk as needed anyway.

The dia of the wheel guiding the belt is easily used to shape the hollow grind shape. Blade tip 'up' technique and gentle pressure and you can see the grind right to the edge and straight accross as the tiny line of spark guides you straight.

Finish up with a finer belt grit if you need to.

Older screwdrivers from classic US mfg are good steel and make great gunsmith tools. Don't pass up giveaway mangled tipped blades used/abused by previous owners or even Phillips tipped drivers. They're all going to be reground anyway to your wishes.

No they won't all match and won't look like a Larry Potterfield video back drop bench,,but they will do an excellent job for you.

Plus you learn very quickly how to shape the blades so you can make what you need when you need it in the future.

I seem to remember that "someone" sold( or sells)a "jig" tro grind screwdrivers with. It may have been Brownell's.

Mike

Just thought I would add grinding screwdrivers and wood chisels are fraught with the problems of over heating when grinding using a high speed bench grinder in consequence ruining the blade's temper. So to end this frustration I would seriously recommend one of these grinders, you get the best of both worlds fast but hot grinding of tools and slow cool and wet with no change to the blades temper guaranteed. I seriously would not be without one in my workshop. I am not recommending the one in the picture, they come with many names and all look the same so go for the lowest price.

Wet and Dry Gringer?

Must be Chinese.

SRH

I was just going to Jack Rowe it and hand file a couple

I think SDH did an article on this?

But you can always read Damascus's (Ernie) thread on Gunsmithing thread or buy them from William Powell or Pendleton Royal.

If that grinder has a water reservoir, it should be left empty after each use, to protect the "wheel".

Mike

Just thought I would add grinding screwdrivers and wood chisels are fraught with the problems of over heating when grinding using a high speed bench grinder in consequence ruining the blade's temper. So to end this frustration I would seriously recommend one of these grinders, you get the best of both worlds fast but hot grinding of tools and slow cool and wet with no change to the blades temper guaranteed. I seriously would not be without one in my workshop. I am not recommending the one in the picture, they come with many names and all look the same so go for the lowest price.

I have this exact machine and the slow water cooled wheel is ideal for putting initial grinds on tools, the cutting is slow which gives you time to adjust - its probably just as quick as setting an awkward shaped tool up on the cutter grinder.

Grinding turnscrew blades Link above is me using my clarkson cutter grinder to grind the tips on turnscrew blades, they are ganged up in the vice and ground either side at the same angle.

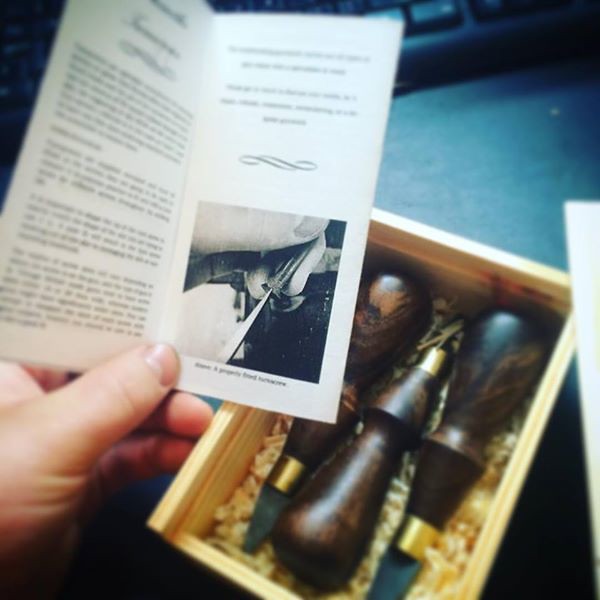

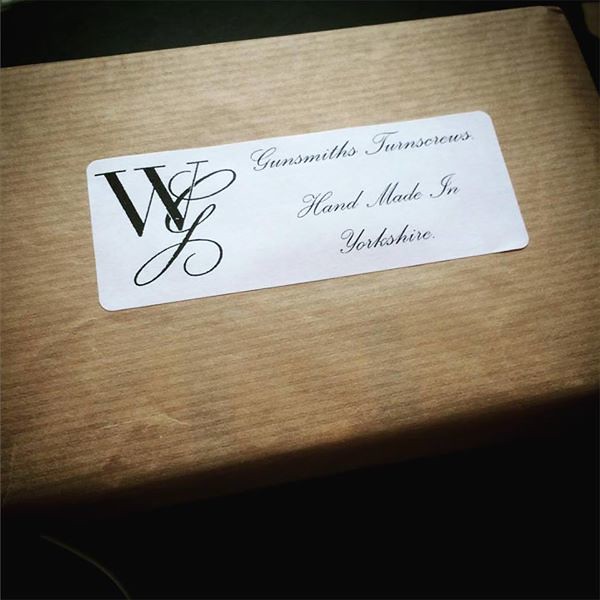

I set the workshop up to offer turnscrews for sale. The biggest issue is that people want to buy a turnscrew and expect it to fit any random screw they might want to turn; the turnscrew is a tool thats always being ground and re ground, on selling them you have to grind a tip that is a one size fits most kinda deal. I also provided instructions for re grinding to fit other screws.

Blade Blanks made.

photo_1048218192013961

photo_1048218192013961 by

james reynolds, on Flickr

Rough out shape.

photo_1048218372013943

photo_1048218372013943 by

james reynolds, on Flickr

Harden and temper.

heattrear

heattrear by

james reynolds, on Flickr

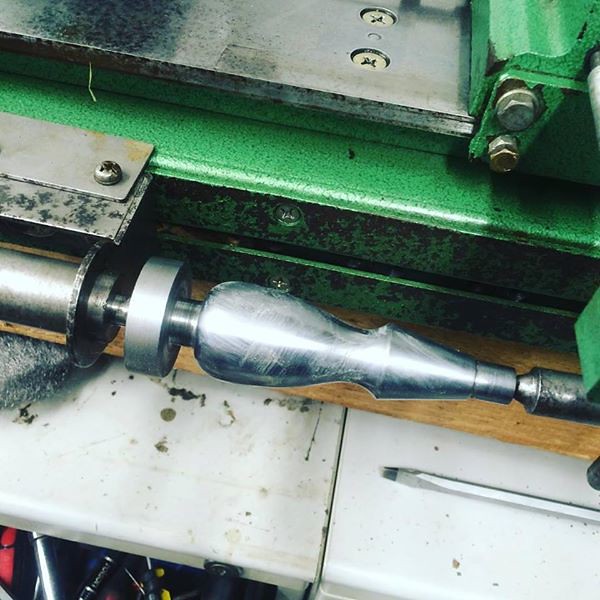

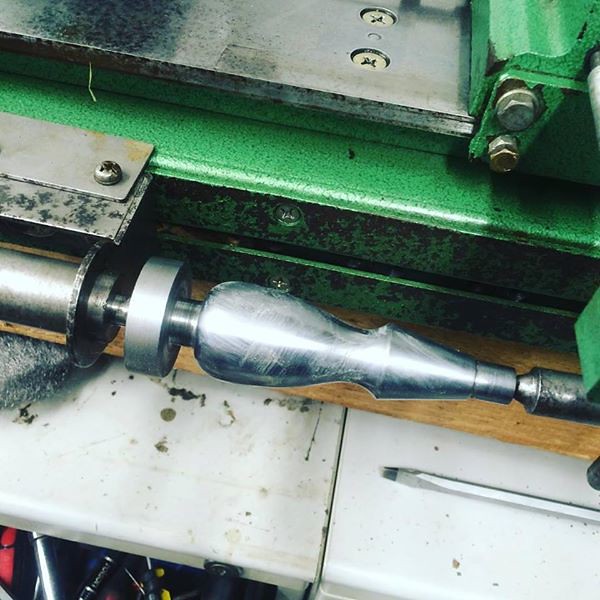

My pattern handle loaded in the duplicator ( i turned this by hand from steel )

photo_1048161932019587

photo_1048161932019587 by

james reynolds, on Flickr

This is the produce from the duplicator ( manually operated )

35920371_1095384430630670_4641952489753542656_n

35920371_1095384430630670_4641952489753542656_n by

james reynolds, on Flickr

Gives good repeatable results all turned from walnut off cuts made into these blanks in the workshop

photo_1052355984933515

photo_1052355984933515 by

james reynolds, on Flickr

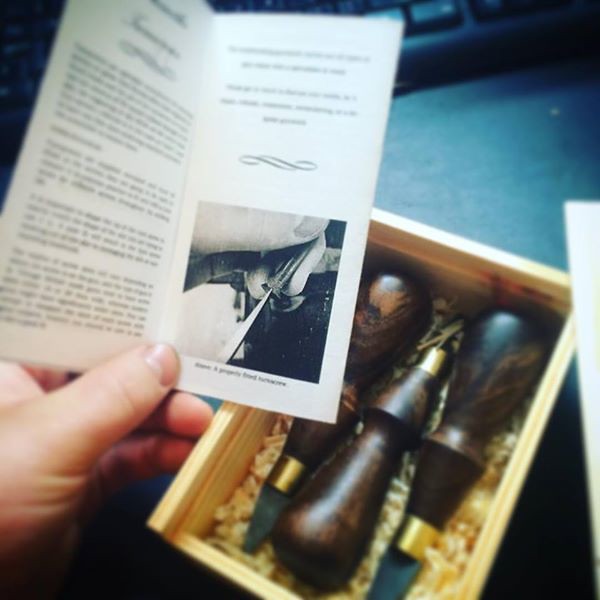

Finished product is boxed up and with instructions on re grinding.

photo_1050754105093703

photo_1050754105093703 by

james reynolds, on Flickr

photo_1050665511769229

photo_1050665511769229 by

james reynolds, on Flickr

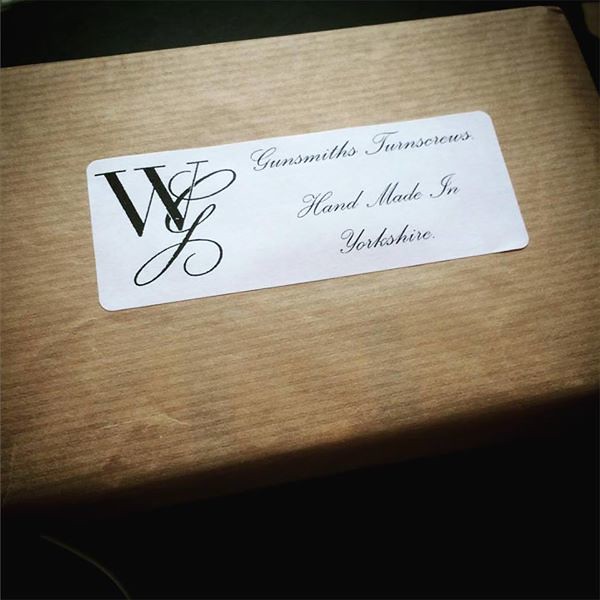

boxes made and printed in the workshop too.

photo_1049428035226310

photo_1049428035226310 by

james reynolds, on Flickr

Example.

photo_1049083631927417

photo_1049083631927417 by

james reynolds, on Flickr

photo_1027331270769320

photo_1027331270769320 by

james reynolds, on Flickr

Ive even sent some to the states with hex holding bits in them for brownells bits.

tsf

tsf by

james reynolds, on Flickr

photo_1048158828686564

photo_1048158828686564 by

james reynolds, on Flickr

The pattern is vesatile as depending on what blank i load in depends what result i get out, slab sided and 8 sides blanks are nice!

Untitled

Untitled by

james reynolds, on Flickr

The round and slab sided ones are in walnut and the 8 sided ones are in best fiddleback English Ash from a tree felled from my childhood family home.

This whole project was started with some turnscrews i made up for my own use a couple of years ago.

Those beautiful, thank you for sharing!

Beautiful, wonderful handles. I hate making handles.

Usually use file handles, cut off dowels, golf balls, etc.

More power to the beautiful work.

Chuck

photo_1048218192013961 by james reynolds, on Flickr

photo_1048218192013961 by james reynolds, on Flickr photo_1048218372013943 by james reynolds, on Flickr

photo_1048218372013943 by james reynolds, on Flickr  heattrear by james reynolds, on Flickr

heattrear by james reynolds, on Flickr photo_1048161932019587 by james reynolds, on Flickr

photo_1048161932019587 by james reynolds, on Flickr 35920371_1095384430630670_4641952489753542656_n by james reynolds, on Flickr

35920371_1095384430630670_4641952489753542656_n by james reynolds, on Flickr photo_1052355984933515 by james reynolds, on Flickr

photo_1052355984933515 by james reynolds, on Flickr photo_1050754105093703 by james reynolds, on Flickr

photo_1050754105093703 by james reynolds, on Flickr photo_1050665511769229 by james reynolds, on Flickr

photo_1050665511769229 by james reynolds, on Flickr photo_1049428035226310 by james reynolds, on Flickr

photo_1049428035226310 by james reynolds, on Flickr photo_1049083631927417 by james reynolds, on Flickr

photo_1049083631927417 by james reynolds, on Flickr

photo_1027331270769320 by james reynolds, on Flickr

photo_1027331270769320 by james reynolds, on Flickr tsf by james reynolds, on Flickr

tsf by james reynolds, on Flickr photo_1048158828686564 by james reynolds, on Flickr

photo_1048158828686564 by james reynolds, on Flickr Untitled by james reynolds, on Flickr

Untitled by james reynolds, on Flickr