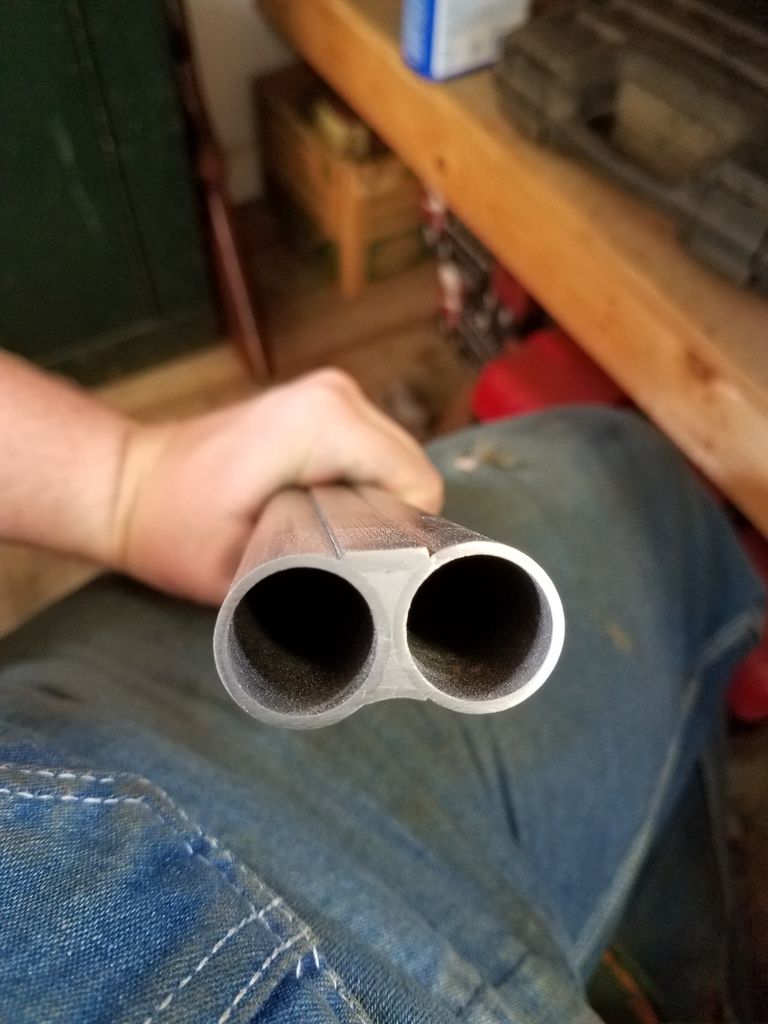

I have a crescent 12 gauge that I am restoring and found a crack in the right barrel starting at the muzzle and extending straight back 2-3cm. Was planning on sawing this off. I was planning on soldering the end up. Any tips or advice. About how much can I take off before I loose all of the choke? Thanks, hereford

Typically, shortening barrels from say 30" to 28" still leaves a bit of choke. But you would have to measure the bores from the muzzles back to the actual bore diameter to know for sure because different manufacturers used different reamers, tapers, and configurations. Also, the chokes may have already been reamed or honed by someone else.

I know it's just a Crescent, which isn't really collectible, but another option is to attempt to weld the crack in the muzzles, using a copper plug to back up the weld on the inside. Then lightly clean up the weld on the inside and strike off the outside, and re-blue. It would be important to keep the solder joints of the muzzles and ribs cool enough to keep them from separating. I certainly wouldn't recommend welding on a barrel further back, and even question the practice of using TIG welding instead of solder during sleeving. But pressures are as low as they will get at the muzzles, and if it didn't work out, you could still trim them back. And it would be good practice in case you ever find the same situation and wish to save another gun that is collectible.

Thanks for info! I've thought of having it welded but all I have is mig and stick. I really don't have anybody I could send it to that would be willing to weld on a barrel. Like you stated it's not worth anything and sending it off for other specialty work cuts into budget since all I'm out for refinishing stock, case hardening receiver, and bluing is my time, labor, and a little supplies. Keep it coming! Hereford

Do you have a center finder to assist in drilling the hole for the bead

perfectly centered on the rib? If it is off .001" it will be terribly noticeable.

Here's what you need:

http://www.brownells.com/gunsmith-tools-...er-prod592.aspx SRH

Neither MIG (metallic inert gas) or stick- SMAW (shielded metal arc welding) are correct for repairing the barrel(s) on your Crescent double gun-- glad you knew that. But TIG (tungsten inert gas) is also not the right process, as the high heat input in the HAZ (heat affected zone) will cause the soft solder in the ribs to disolve, and causing even greater problems. And heat input when welding on any pipe or barrel can cause an "out of round" result, unless you use the right process and preparation.

Looks like your barrel shortening process came out OK, as judged by your detailed fotos.