Soft steel carding wheel - 05/04/17 04:39 PM

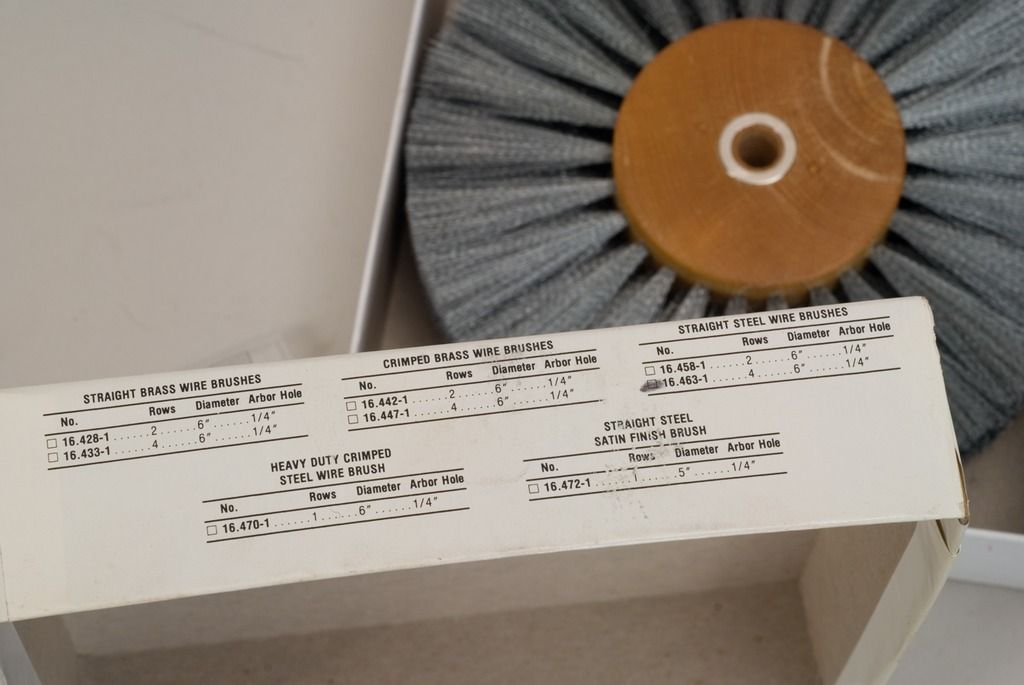

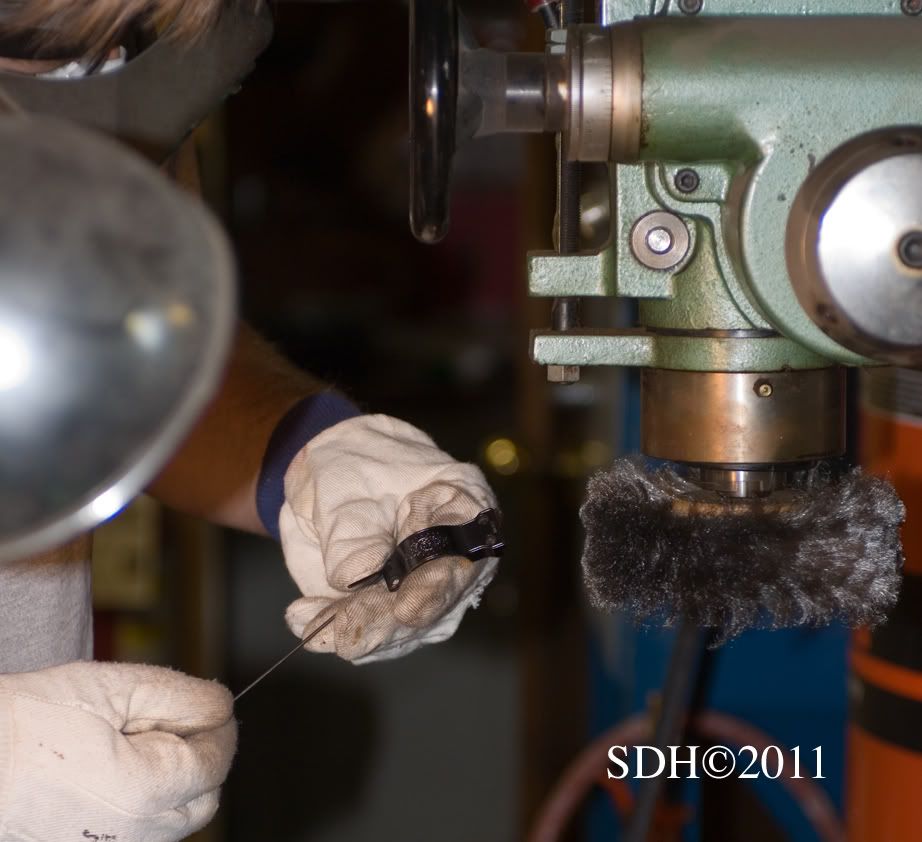

Does anyone have another source for soft steel carding wheels other than Brownell's? They are out of both the 2 and 4 row, and have been for a while it seems. Anywhere else to look for one? I'm not coming up with anything.

I can keep going with doing it by hand all the time, but there's some growing joint discomfort, and since I have a Baldor pedestal polisher on hand, why not use it?

Thanks.

I can keep going with doing it by hand all the time, but there's some growing joint discomfort, and since I have a Baldor pedestal polisher on hand, why not use it?

Thanks.