This salesman's sample came from the Baker Gun & Forging Company located in Batavia, N.Y.

I would guess it is of Belgium manufacture as there were some other salesman samples in boxes that had a Belgium address.

I purchased this, along with some other items from the grandson of the last president of this firm.

Oscar Gaddy refinished the finished end many years ago. With the resurgence in the interest in Damascus barreled guns, I thought some of you might enjoy these photos. One photo shows the remains of the mandrel sleeve.

Chris

Neat Chris! Are there any markings on the sample rod to suggest their origin? May I add those pics here?

http://www.picturetrail.com/sfx/album/view/19006385Very similar pattern on this Baker

Chris, that is simply amazing!!! You are a lucky man to have that in your collection and a gentleman to share it with us.

Thank you very much.

Tim

Its pics and names that at times pop up realy make a person miss Oscar,Bill Wise and Herr Klunkermiester.God Bless them

I went ahead and made an album just for demonstration rods

http://www.picturetrail.com/sfx/album/view/20091342

http://www.picturetrail.com/sfx/album/view/20091342

That is simple awesome. No matter haw many descriptions you may read about how it was done, those pictures are better.

Thanks for sharing!

Revdocdrew,

I would pleased if you used the pictures. There are no markings on it that I can find. I let Oscar examine it for quite some time. It prompted him to buy an English barrel sample at auction to include in his damascus display.

Chris

Pics are up Chris, with Dr Gaddy's. Thanks again!

Chris,

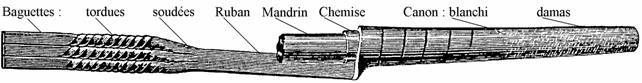

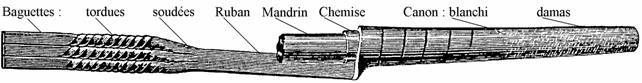

Very nice example. That is not the mandrel, it is the chemise. The mandrel is a stolid steel rod. They wrapped the chemise around the mandrel before they started turning the riband. The mandrel had a fixture that was attached at one end. This fit into another fixture that allowed the assistant to turn the mandrel over the anvil wrapping the riband around.

Pete

Pete and Drew, this is the first sample of damascus construction I've seen that the beginning of the billet is composed of quite large sections of iron and steel. It appears the blacksmith then draws out these large pieces into the smaller billet we're used to seeing. I had thought the small billet, composed of many smaller pieces were supplied by the rolling mill in finished form. What do y'all think?

Joe,

I noticed that as well. Certainly a unique approach. I have never seen it done this way before nor have I seen any written references to such a technique.

I guessing they are trying to show what the rolling mill would have done. They seem to be simply stacking iron / steel. Although the proportions are very large... This is a demonstration barrel after all.

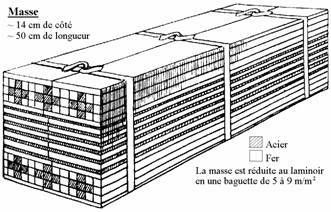

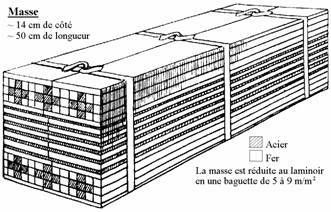

This would have been the normal billet construction before being rolled.

This shows the chemise. If you look closely you can see the split. The chemise would have stayed with the barrel through out the forming. The smiths were constantly removing and inserting the mandrel. I believe it kept the barrel from being welded to the mandrel. The chemise would have been removed during the initial boring.

What is missing is the collar and handle that would have extended to the right. Also the material would have been at a right angle to the mandrel during the forming, but you already know that Joe.

Pete

Very, very cool Chris!

And after recently viewing PeteM's Damascus documentary, even more meaningful.

Thanks,

Steve

Pete, I loved the DVD documentary.

Tim

Chris,

Looking at the far left side. When you view it head on, are these solid pieces of iron and steel?

Glad you liked it Tim. There are still many questions.

Thanks,

Pete

Pete, I agree that the rolling mills probably supplied the finished billets in the time period we're generally concerned with. However, I suspect that the construction techniques were evolutionary. That is, early on the blacksmith himself probably drew out the metal into usable billets and began the process using rather large pieces of metal. This is very doable and lends itself well to what a small shop was capable of doing and considering the lack of communication,transportation and demand it seems most likely. Then I can imagine as patterns became more complex and the industrial revolution progressed that specialized rolling mills took over the duty of constructing the billets. Of course this is mere speculation on my part but it seems logical.

Joe,

You are correct as usual. We know that the rolling mills did not come to Belgium in a "big way" until the 1830's. By 1856 Higny had produced a sheet with 20 different patterns. There were patents being filed in the 1890's for various patterns in Belgium. Also, the rolling mills themselves were under going change. I have seen engravings of the early mills that were hand operated. By about 1880 this had changed.

It is one of the difficulties of the research. A description from 1910 simply may not apply to the process in 1810 or even 1880.

Pete

Attached is a picture of the end. Also is a piece from an Ithaca that Oscar re-finished for me. My appologies for the poor picture quality.

Chris

The gunsmiths, blacksmiths, forges and furnaces were more connected than one might think because other than weapons being taking from waring factions, this connection was where most of the transfer of technology occured and it was all centered around the mines and hydraulic power. John Cockerill arrived in the Liege area circa 1817, which was a part of the Netherlands, and he and his family designed/made spinning machines since by law the technology couldn't be taken from Britian. Withh the Meuse River nearby as well as the mines and other essentials, they also started to produce steel and in 1826, according to some sources, had the 1st coke fired blast furnace in Europe. Quality pattern welded tubes takes quality steel and up until the time John Cockerill was shackled w/ the task by William the 1st of the Netherlands, Belgium's steel was lacking. By 1838 Cockerill had it all: blast furnace, foundary, rolling mills and forging mills. So the rolling mills that produced billets could have shortly followed the blast furnace technology of 1826. BUT, revolution was at hand and the Cockerill steel works ceased production during this time and I almost everything else followed(If my memory of history rings true, I think it is here that cotton production left Belgium and headed to the South States(USA)). The Netherlands were dissolved in late 1830 and Belgium had some sort of constitution/ruler by January of 1831 but the Netherlands didn't recognize Belgium until 1838.

Kind Regards,

Raimey

rse

Chris, With one picture being worth a thousand words, thanks for thousands of words woth of very descriptive knowledge. Seeing what's involved makes you wonder why Damascus guns don't sell for many times what their fluid steel counterparts do.

Looking at the steel all extended out like that really makes me wonder how Jean Delcour and his crew ever figured out how to "write" names in the Damas. And then to do it over and over again in the barrel, quite amazing. It is a shame that damascus barrel making is a lost art. But if they were made today we probably would not appreciate them as much as we do. I really sorta hate to buy a gun that doesn't have a set of damascas barrels on it. Seems that a gun with fluid steel does not have much personality. Even though I do own one or two of em.

Priceless piece of gun history.

Thanks for the kind words. I've always admired this piece. It gave me much greater appreciation to those workmen who made damascus barrels. It is quite the labor intensive process. I think about how much time it took to make one tube, then try to visualize how many tubes were made! A little overwelming, to say the least.

My thanks go out to those who have spent so much time researching this fantastic subject.

Chris