It is such a pleasure to see such fine workmanship. Each part shaped, fit and polished to such perfection. What do you think we are looking at in hours? Twenty hours in each lock? Twice that, even more?

At this time, virtually all locks were made by specialists for the Makers, very few in house. So they had economies of scale and highly specialized craftsmen. Also many of the components would have been forged near to final shape and filed up using patterns which saved time. How long? No idea but probably less than one might imagine.

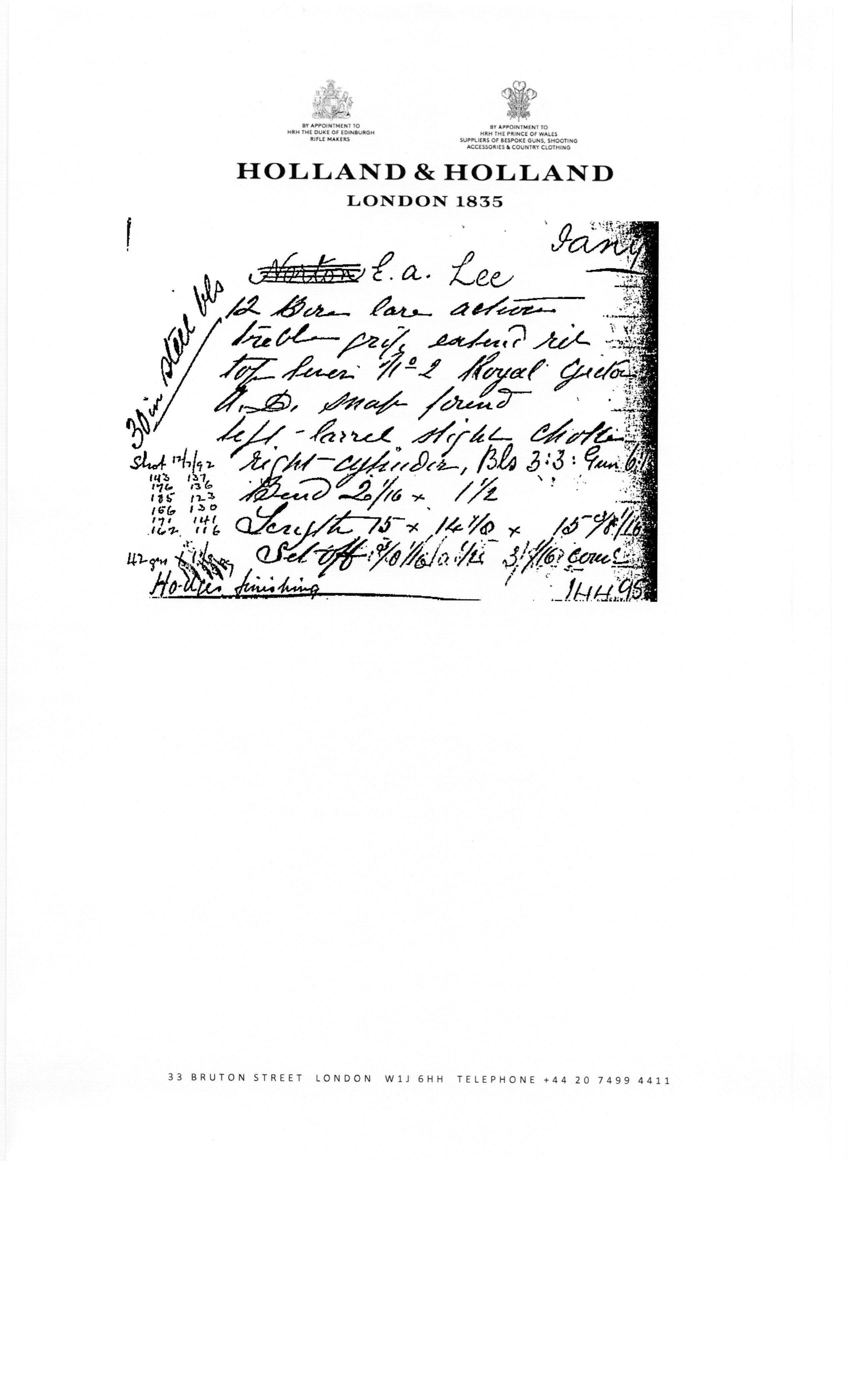

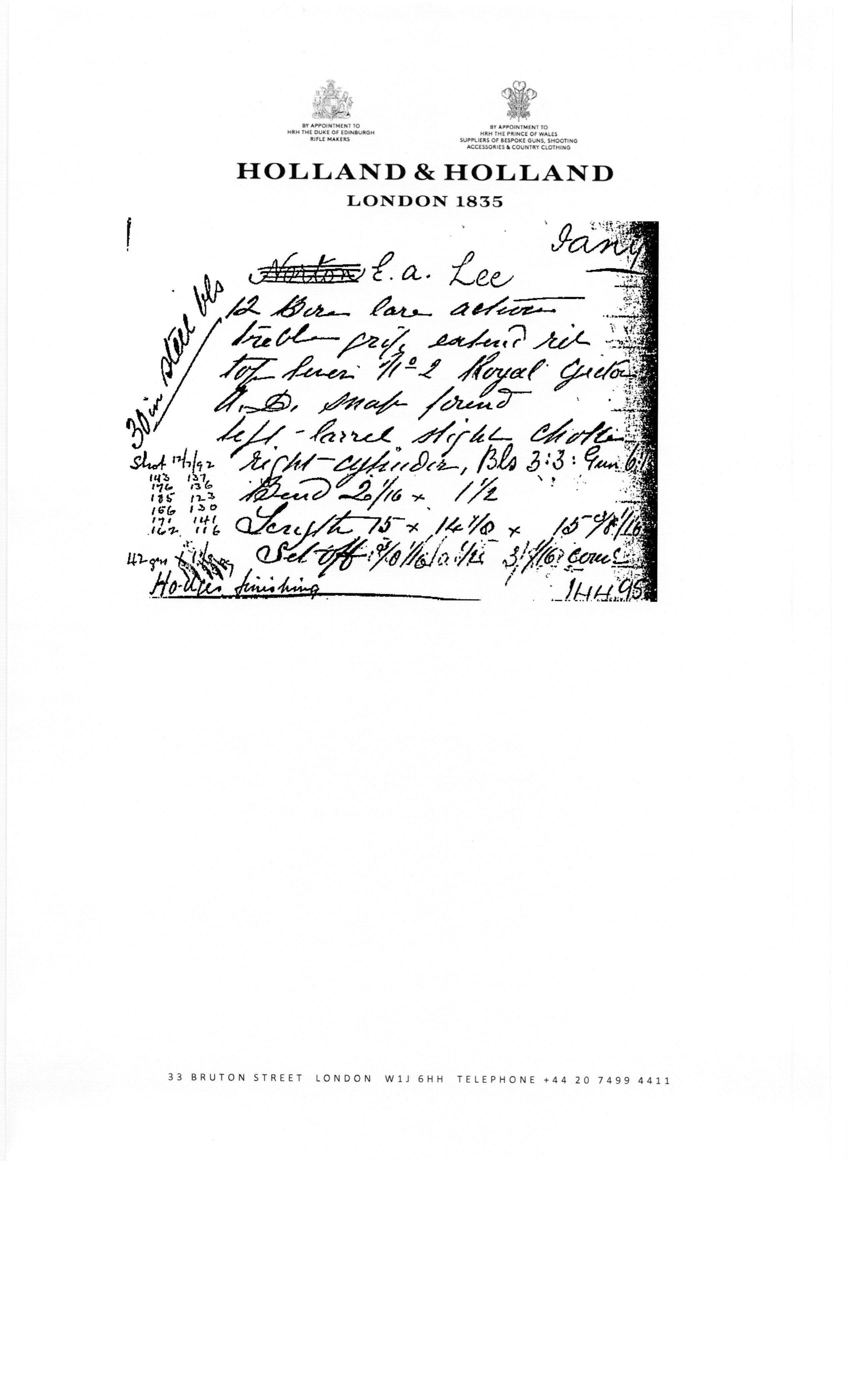

I have a collection of 1870's era unfinished lockplates as would have been supplied to the trade.

All pins are present - heads and back ends are not "finished"

Tumbler axles are round - A jig would make a quick job of filing square tapers on to fit hammers.

All springs are present and functional but in a rough filed condition - possibly as fine as a second cut file.

Lock plates are oversize and the finish is that of a bastard file.

Bridles are present but oversize and afar cry from the refined and often ornately filed bridles we sometimes see.

I would imagine working by eye i would be looking at it taking 20 hours minimum in order to take these "as supplied" lock plates to anything we might see on a gun we might describe as finely worked, whats interesting to me is that when i make springs i carefully polish the inside surfaces before making the bend - clearly this isn't what has been done on these locks and it was left to the gun maker to finish up inside as best as he could.

They are lightly rusted with the ravages of the intervening 140 years in some gunsmiths or others parts box and some have been robbed for stirrups and springs but some are complete or nearly so. Bar action and back action sidelocks and also conventional back action locks too; all hammer gun locks, all rebounding.

They will have had jigs for everything - computers have killed the art of simplifying a complex task by turning it into smaller more achievable jobs.

I would say that the lock plates were probably cut square and then drilled with a hole that is a reference hole for later work holding and becomes the tumbler axle.

plates into a press which would cut the plates to shape.

Plate to drills set up to drill holes in the right place for the right style of bridle. holes then tapped - then as now to speed things up the taps might have been on a belt driven drill i imagine if you set the belt up right you could stall it out before the tap broke - its not the proper way to use a tap but we have all shoved a tap in a hand drill at one point lets not assume that yesteryear's people were as purist as we might like them to be!

Pins would have probably been mass manufactured either in house or by another specialist.

Ive got some tumbler forgings which will have been lathed down to size a lathe with stops in the appropriate places would have made this easy and repeatable.

Tumblers to a filing jig, which could have been used on a filing machine or grinding machine.

You can start to see the economies of scale, i can see that assuming pins were bought in, tumbler forgings bought in, springs probably pre bent and then fitted if you had a workshop set up for lock plates and men/boys/women/ or outworkers feeding the supply or carrying out specialist tasks you even a relatively small operation might be producing hundreds of gun locks a week - the purchase and setting up of equipment and specialist tools was probably more expensive than any workers time.