Found an English translation of a Belgian (in French) article about damascus production

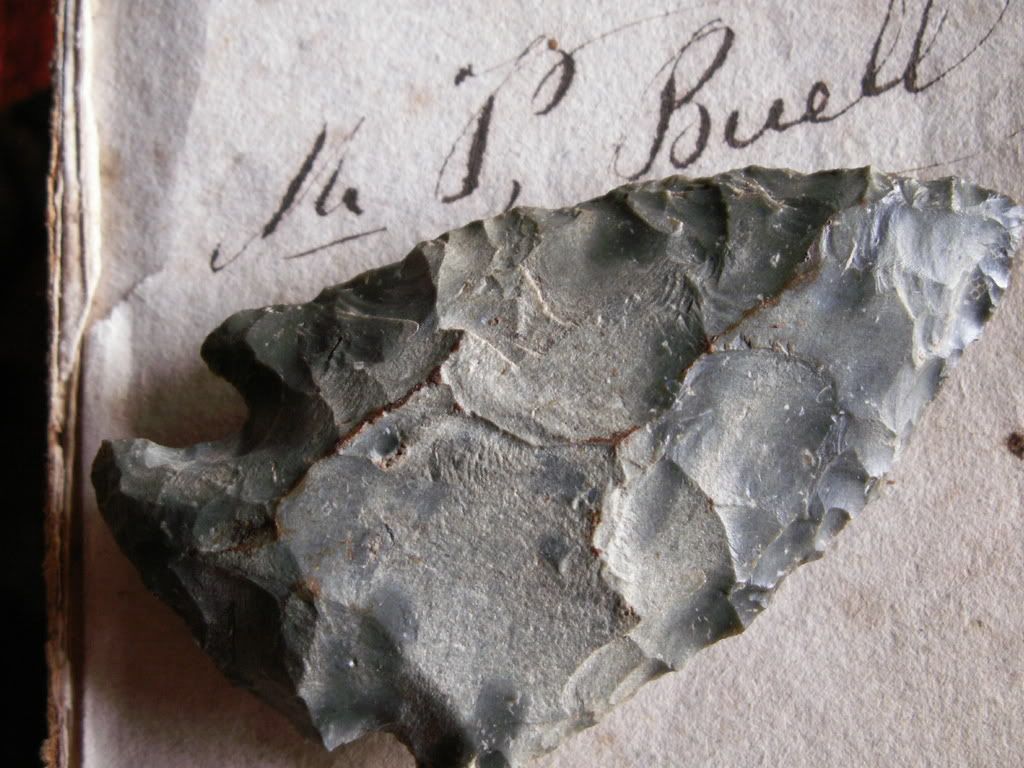

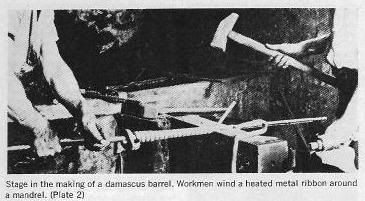

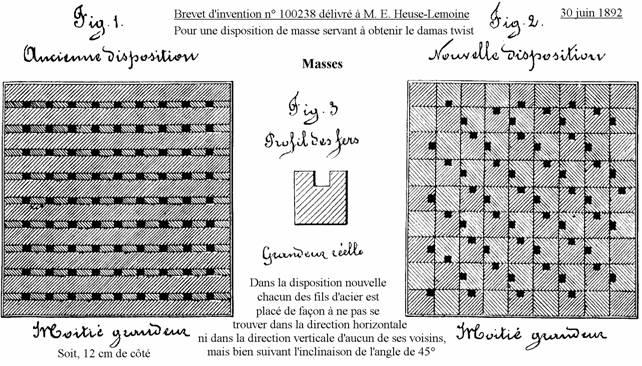

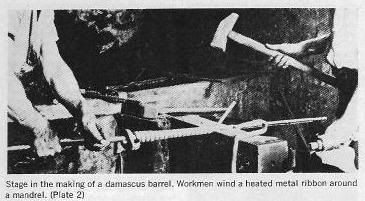

Looking at the end of the 'ribbon', one can understand the various patterns that can be produced by alternating the tiny iron bars with steel. The 'Damas' illustrated certainly looks like what Lefever (and others) called 'Horse-shoe' damascus.

Lots of new stuff on the 'Damascus Barrels' PictureTrail

http://www.picturetrail.com/gallery/view?p=999&gid=16082038including an amazing Parker brl with 'Terell' in the damascus pattern.

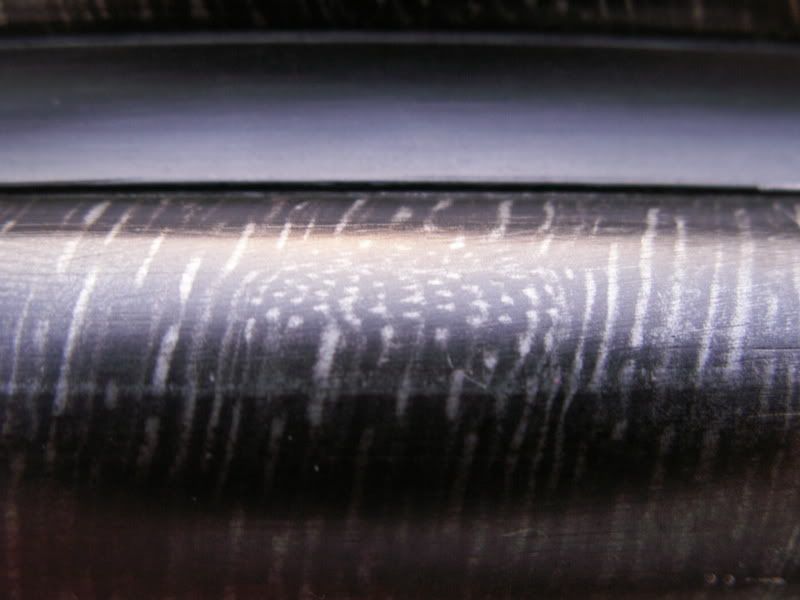

The strips of iron and steel in the 'ribbon' shown will produce a pattern similar to "Bernard" damascus. Also note the tiny 'roses' in the right barrel.

Just had a very gracious offer from one of the regular contributors here to share illustrations of about 30 damascus variants. My long suffering but much smarter spouse will get it scanned and added to the PictureTrail on arrival and I'll post when it's up.

Would still like to add high resolution close-up pics of some high grade Parker and LC Smith damascus. Please send by JPG attachment to revdoc2@cox.net and thanks!

And for your enjoyment, by C.J. Opacak

Dave Miles comes through again!

He has a copy of the excellent article covering the Belgian damascus barrel makers from the April 1976,

American Rifleman "Making Damascus Barrels"

Send me your e-mail address if you'd like me to forward the copy (

please tell me I can't get in trouble for this!)

Thank you both! Brings thots of geezers before they were, old guns that weren't and dogs that knew what they needed to know to please their masters long before there were rings or trials.

Oh, and I like the fact that the rib is joined to a piece of homogenous steel for the doll's head, too.

You can send me a copy please,

gregandleesa@paradise.net.nz

BTW I cannot get private messages to work.

Cheers,

Greg

RevDocDrew, pls add me to your email list.

sdvdiamond@yahoo.com

Thank you, sv

Drew,

Send it my way. I believe you already have my email address. Flues barrel pictures coming your way soon.

BTW, are you part of my American Rifleman email group? I haven't had time to send out any articles in the last few months but I have about 100 articles back to the '30's that I have scanned and emailed.

Me, too!

hfn_03570@yahoo.com

Thanks a lot.

OWD

Since the theme seems to be Remington 1894s-Greg Martin's internet catalog is now up with some amazing guns

http://www.gregmartinauctions.com/gma/catalogs/june07_catalog.html I just 'borrowed' pics showing the super-fine EE & DE damascus, and the A grade ('Oxford') 2 Stripe Crolle damascus below and added them to the PictureTrail

Here is a thread about making damascus for knife making. The guy that is doing this is not a barrel maker of course, but he is some sort of Guild-equivalent master of this sort of work. He has some video clip of the early part of the process and some discussion of what's happening.

There are lots of pretty knives out there, but his are a "cut above" the rest. Pun perfectly appropriate.....

http://shilohrifle.com/forums/viewtopic.php?t=8758Meanwhile some beautiful barrels here and I could stand to learn a lot about the different English damascus guns that I have (3 rifles, and several shotties).

Me too! Would like copy of article, thanks.

I tried sending a PM, but couldn't get it to work...."error on the page"

smilinjohntoo@yahoo.com

John

Yes, Please send me a copy also at kopkaie@msn.com

Thanks

Iggy

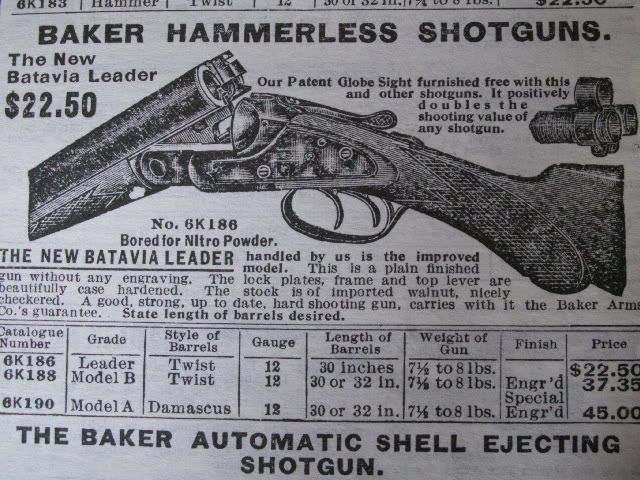

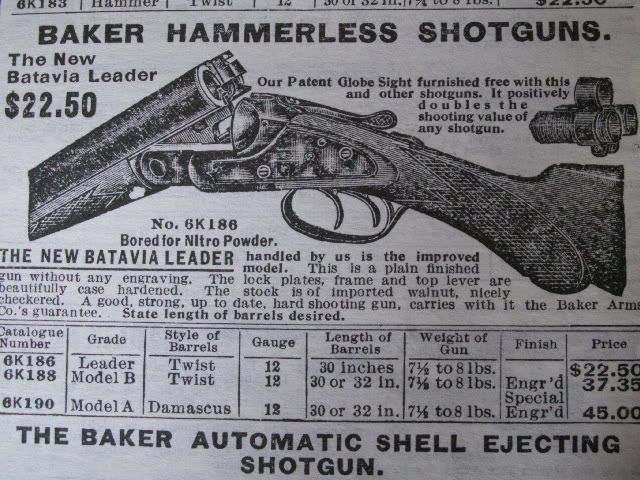

Found some more excellent pics of Lefever and Baker damascus on the Greg Martin Auctions site, including this Optimus (which

might be Truk Extra or extra fine Turkish damascus)

I also asked the Remington Society if they can come up with the name used on E and D Grade 1894s. Should have the 1899 Parker catalog reprint soon and the poster illustrating about 30 kinds of damascus (which we'll scan and post.)

Many thanks to Pete M who graciously shared a c. 1900 product brochure by a Belgian brl maker. Some detail was lost in the scanning and posting, but it's up now

http://www.picturetrail.com/gallery.fcgi?p=999&gid=16082038Interesting findings include several examples of a One Iron Crolle-Twist Laminate and 5 grades of "Turkish damascus" which appears to be what US gunmakers primarily used, but which was given names like "Boston, Oxford, Washington, American Flag, Horseshoe, etc." for marketing. The Lefever brls in the previous post look like either 1st quality Bernard or Leclere.

Dr Drew,

Glad you got it. Here are some more images.

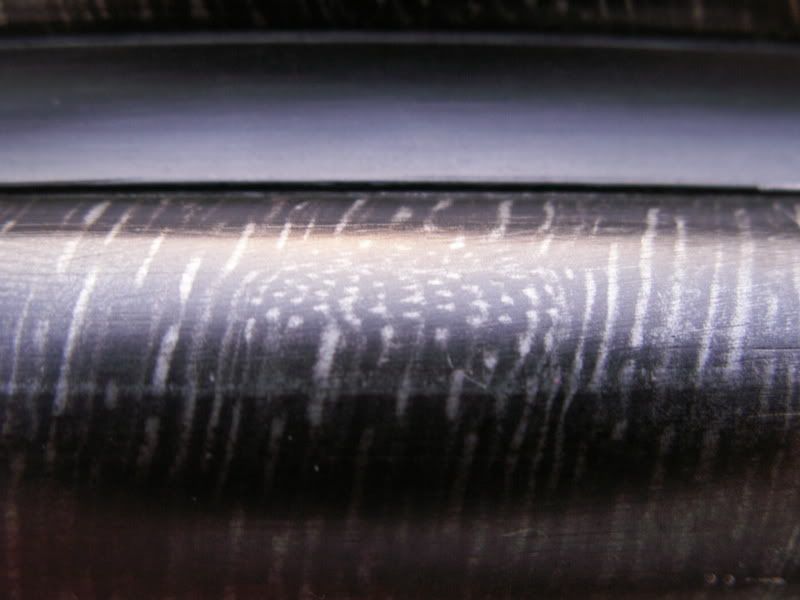

Remington 1894 C grade - Star Damascus. Notice the rib.

Embedded name Zenobe Gamme. Dr Gaddy once posted some actual photos of this type of work. I just did not save them. Maybe some else did. Hopefully they will post them.

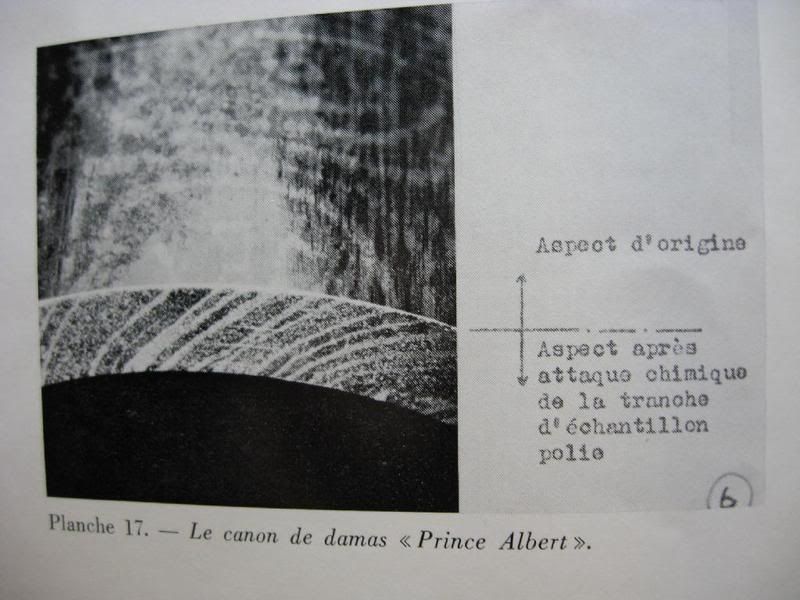

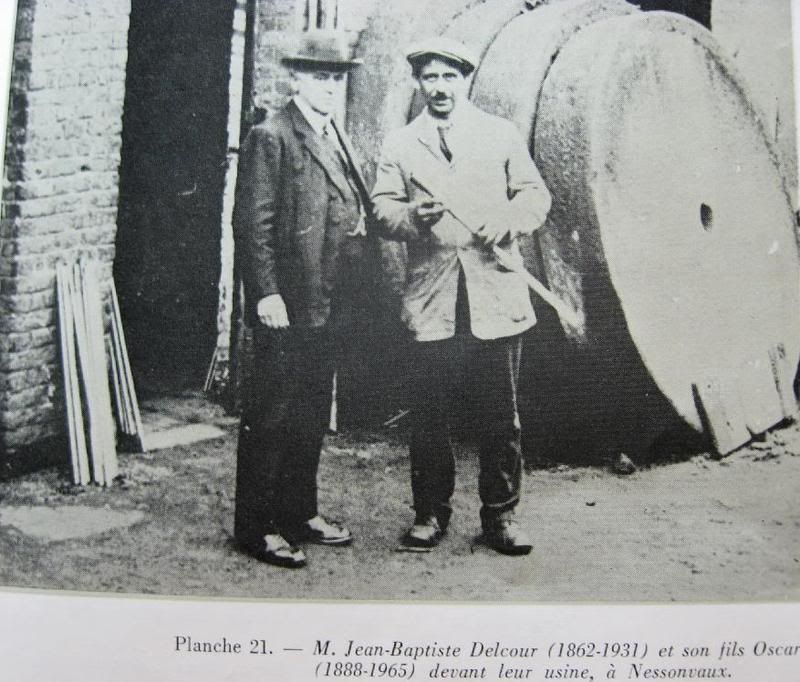

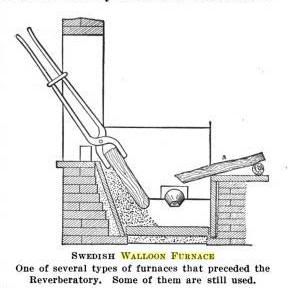

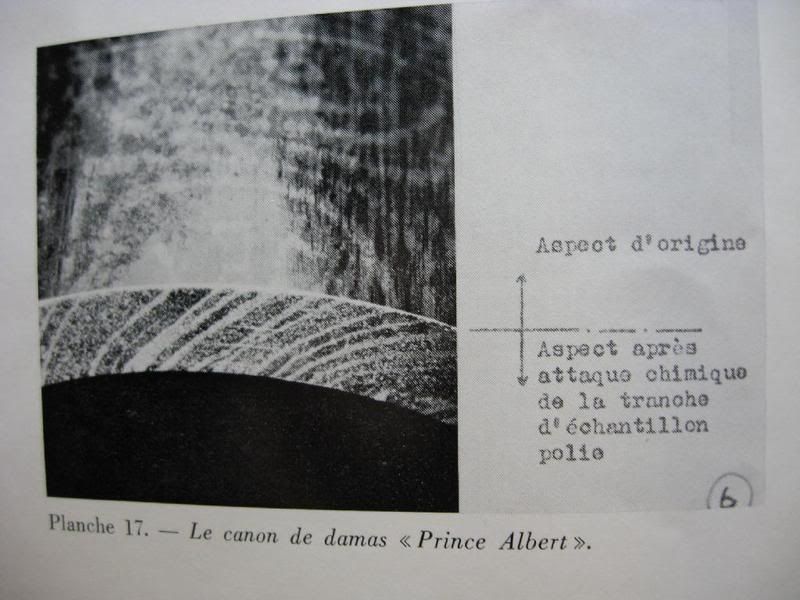

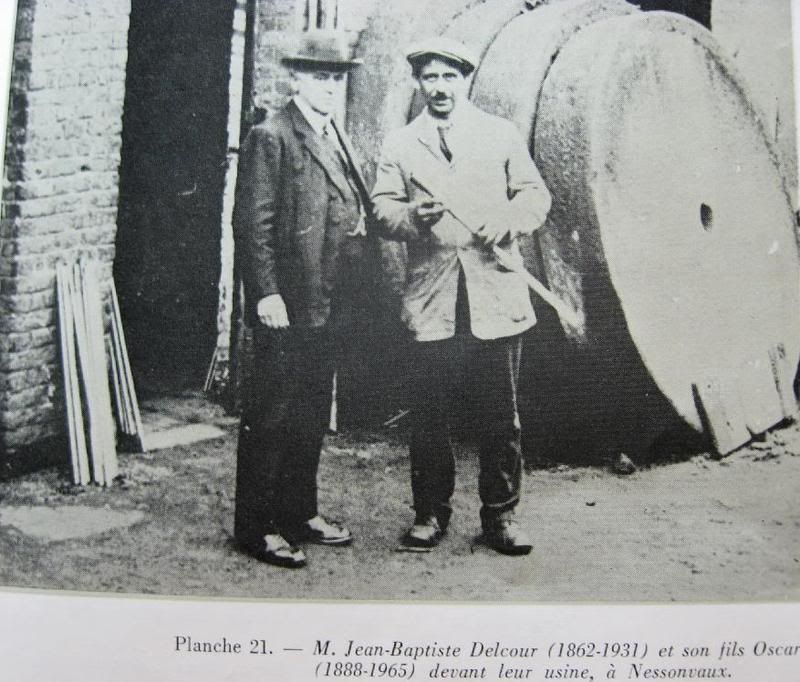

From Puraye's Le Damas. Identified by Gaier as one of the last workshops still making damascus tubes circa 1920

Modern Damasteel. A very different product with some resemblance to traditional damascus

Pete

Let us remember that Damascus knife blades are completely differeent from Damascus gun barrel. Both are beautiful, however. I have obtained a bunch of twist and Damascus steel baeel cut offs that I am going to have made into knife blades. For the proper edge hardness, there will be a center core of regular knife steel. Should be very neat.

Pete

Received the Parker Bros. 1899 catalog re-print from Cornell Pubs, which confirms that G and D Grades had what Parker called "Fine Damascus" Here is a 1899 DH with fine '3 Blade Crolle'

C Grade guns had "Fine Bernard Steel" and

I'd sure like to archive an example. Anyone with a damascus brl C Grade, please post a high resolution close-up here or e-mail by JPG attachment revdoc2@cox.net and thanks!

FINALLY found a high resolution close-up example of "Bernard" damascus on Keith Kearcher's website; recognizing that their are several 'quality' designations for "Bernard" and many makers

Rev, I sure would like to add to my American damascus/twist files if you have anything...I only have a few bits and peices and some of are for faux damascus...You don't have to answer if you don't want to, I am aware that American damascus and faux damascus were "off limits" subjects [here] in the past...we can exchange info privately if you think it may help to avoid a pissing match by angry readers..

.

Did you happen to catch that episode of Globe Trekker (in Spain) were they claimed the history of damascus steel is interwoven with the history of flaminco (sp?) music and dance?

RC - didn't see that episode. Were they refering to the twisted laminate we refer to as damascus for gun barrels, or were they refering to actual Damascus blades made from Wootz. The two are different. I've never heard of Spain being a developer of laminate metal.

Robert: I suspect everything shown on the 'Damascus Barrels' PictureTrail is English or Belgian

http://www.picturetrail.com/gallery.fcgi?p=999&gid=16082038and I only have one 'Faux damascus' pic (the last one)

Missed the Globe Trekker episode. Lots of stuff out there about damascus blade production (much less about gun barrels). The Moors controlled much of Iberia from 700-1200, and Grenada until 1492, and no doubt brought sword blade 'technology' with them. These folks claim the Flamenco came from Middle Eastern Dance

http://www.middleeasterndance.net

according to the program that I saw...there is a valley in Spain were it is said that Flamenco music got it's start aganst the constant backdrop of ringing anvils that went 24 hrs a day on both sides of the valley.

.

Twenty years ago I read where farriers across Europe saved the worn and headless horse shoe nails for re-use in the damascus steel process. It was theorized that the nails had enhanced grain properties due to the horses constant pounding on the cobblestones. These nais were then straightened, filed, and welded with a blacksmith weld, into long somewhat square rods. These rods where then filed, to open the grain, and bundled into packets, with ground bone dust, to be forged and twisted into damascus or composite steel. This is probably nothing new to you guys.

.

What interests me is the damascus [gun barrel] steel that was made near Ithaca and in New York City and Boston. I guess I'm also interested in the damascus steel axes and hatchetts from around America, but mostly the the ones made by the Seneca Indians in Lackawanna NY, some under the name Buffalo Black Axe. The federal government played a role in setting up the steel industry in Lackawanna, mainly to employ the Senacas who were being forced to give up their hunting and gathering metheods of survival. I've heard, but not seen, that some of the best L & IJ White carpenters tools where available with Seneca made damascus. L & IJ White hand tools have always been too pricey for me to collect.

.

Jerry Swinney once explained to me how the barrels makers of Motts Corners (near Ithaca), who made thousands of barrels for the Civil War effort, continued past the war into barrel steel for sporting guns. It was this skilled human resource coupled with the hydraulic water power thats exists in both Ithaca and Motts Corners that led to the founding of IGC. Before Jerry passed, I photographed most of his material. Now his edited notes are available commercially for about $300 in three volumes. I don't know if the Motts Corners material made into his books [posthumously]...glad I got a unedited copy the way I did.

.

Once again my digital camera is loaned to a friend who is taking a run at ebay...tomorrow or Saturday, when I get it back, I'll start posting some hard evidence for your files...

.

seems to me the the American Rifleman published an article on American damascus hatchetts and axes (in the 20's)

.

Rocketman, maybe I am mistaken, but wasn't Nikolas Bis from Spain? Isn't the Bis name synonymous with European damascus?

.

Rev, is that damascus picture trail your doing? It's great!...Either way, did you notice in the photo labeled "ribband" wound around a mandrel, that there is something strange. I think that winding was a factory reject that couldn't be finished...and it looks as though someone has purposly altered it to cover their tracks (as to winding and proper welding)

Robert,

Interesting information. I was able to turn up 2 names in the 1870 census, John B Lull (or Luff) and Benjamin Losey. Both listed their occupation as gunbarrel maker. This is for the Caroline, Tompkins County, NY census track, which for all practical purposes takes in Motts Corner.

What is IGC?

For a picture of Swinney

http://www.remingtonsociety.com/events/8th/Jerry_Swinney.jpgPete

seems to me the the American Rifleman published an article on American damascus hatchetts and axes (in the 20's)

Do you happen to know what year? I have most of the latter '20's in my collection.

Drew,

I haven't had a chance to take a picture of me etoile/'American Flag' damascus barrels but it seems you now have a good example. Do you still want a picture?

Pete...Yes... I think the water driven forge at Motts Corners became Losey & Lull (partners) for a period before becoming a blanket factory...One of the Losey decendants is, or was a member of this bullitin board system a few years back...IGC is Ithaca Gun Co...That's a great picture of Jerry...he looks like the actor from the movie "Cocoon" in that picture...I met Jerry around 1980 and kind of modeled my research/collecting after him...he told me some wild stories...based in fact...the most unusual was shortly before he passed, I was taking photos of his hand written files, fast and furious, while Larry Shuktnect was taping voice interviews with him. During one of these interviews, Swinney claimed that the unsolved mysterious common denominator that ran completely through his body of research was...how very many of the gunsmiths, that he spent his life chronicling, had passed away from tuberculosis (with no other explanation)...

.

People think the Swinney files are the definitve work on NYS gunsmiths...but I can assure you, those files are only the tip of the iceberg...

.

Utah...sorry, I'm not sure when without tearing into my own collection

How about this early Parker Twist barrel, that is mostly steel, with little iron. Thus the gray color.

RC - couple of things. The horseshoe nail thing was very likely done, although I've heard several versions. There would have been no special properties imparted. But, they were a good source of salvage steel.

I'd bet on the gunsmiths' demise from "tuberculosis" was actually silicosis from grinding barrels. Brit barrel makers had the same problem.

Sorry, but I don't know any details on Bis. Lot of good stuff here. Keep it up!!

Dave's barrels are very interesting and I've been following the thread about them on the PGCA Forum and was waiting to add them to the PictureTrail after something definitive was decided

http://www.parkergun.org/forums/forum1/3714.htmlOne of the articles I've found states that STEEL STAINS BLACK AND IRON WHITE/SILVER after the acid etching.

Is this correct? so the brls have a LOWER steel/iron ratio than the usual damascus? Dale told Dave that he thought the brls didn't take color because of the high

steel content? Apparently Parker briefly made their own damascus brls?

Mike: I would like to add your 'American Flag' brls to the PictureTrail. Please include the make, grade, and year of production. You can post the pic here or send by JPG attachment to revdoc2@cox.net and thanks!

Just called Dale Edmonds, who was quite helpful. He confirmed, and apparently Dr Gaddy discussed in the 97' Double Gun Journal articles, that iron turns black and steel turns white, probably because the oxidation is removed much easier from the steel. Issue settled

DaveM...whats that patent date on the barrel flats of your Parker? It looks like Apr ?? 1876...can you tell me that exact date please?

.

sorry, I don't understand the info about mostly steel and a little iron....maybe someone can explain...

.

I thought steel was an iron alloy, made tough by forcing carbon into iron ...aren't the black lines in damascus and twist actually the carbon (martinsite) that was folded into the steel? (carbon from bone and coal)...

.

Please don't get overly technical with the answer...if you could, explain it in a way that could be understood by the thousands of uneducated men who actually made all the damascus/twist barrels. The men who made these damascus barrels knew full well that the objective was to fold and drive carbon into the iron for a stronger, tougher material that could withstand the forces and pressures involved with the end product. stahl- stand fast

.

Rocketman...the thing that gave wootz damascus its charachteristic properties was primarily the naturally occuring impurities at the location of the site where the iron ore was collected. The ironmongers smelting and carbon folding techniques may be reproducable in other parts of the world, but without the original ore source, you can't clone wootz. The thing I find interesting was the forging techniques used by the smiths who used wootz billets. Those techniques can be used on any damascus, especially scrap double shotgun barrels...and guys are...3 or 4 years back, a guy offered me (4 sale at a gun show) a ladder damascus bowie...the guy is an advanced Cattaraugus knife collector, and he named it as "ladder damascus"...I'm not interested in ladder damascus, unless it's real wootz. Far flung as it may sound, I have Albert Paley's hand crank forge from when he was a young man. I live only about 75 miles away from his studio in Rochester NY, also the home of Jerry Swinney. About 15 years ago I used it to forge two damascus swords for and with my two nephews, had I known about the wootz techniques back then, perhaps I would have used them. That was the last of my damascus/twist experiments

Carbon can't be mechanically driven into iron - it must "disolve" in a high heat environment. The chemical combination of iron and carbon forms an alloy we call steel (carbon content over about 0.05%). The folding and heating process exposes more area of the iron to carbon and, thus, increases the rate of absorbation. Case hardening uses the same chemical process, but doesn't expose as much of the steel to the carbon rich casing material. The hazard of mechanical introduction of carbon is that any carbon not absorbed (or contaminate material) will be included in the final metal as a very weak spot. The larger the inclusion, the more detrimental to the strength of the base metal. Removing all extranious material and arriving at a known and controled carbon content, along with avoiding cooling shrinkage voids is the holy grail of steel making. Old time craftsmen did some very amazing work considering the tools, ores, and knowledge they had to work with.

Wootz has been replicated and documented. It produces a nice blade steel, but nothing special compared to modern alloys. Of course, it would have seemed magical to anyone used to using an iron/low carbon blade. Its claim to fame was being workable at low enough forging temperatures to not burn out the naturally occuring carbon and, so, leave you with a fairly high (for the time) carbon alloy. I believe the trick is a very narrow level of mangnese (I could be wrong on that alloying component). Anyone else remember the reports on this?

Some interesting infro on Wootz steel, the first by a damascus expert at Iowa State:

http://www.tms.org/pubs/journals/JOM/9809/Verhoeven-9809.htmlLooks like it's vanadium and molybdenum that cause the damascene appearance of Wootz

http://met.iisc.ernet.in/~rangu/text.pdfhttp://www.brisa.fi/wootz3.htmlhttp://en.wikipedia.org/wiki/Damascus_steelI couldn't find anything about Wootz being used for gun barrels or 'pattern welded' (what we call damascus) steel.

Rocketman...I have driven and folded carbon into mild steel more than I should have, I could have been working for money during that time. The technique is like reloading in that you're stuck adhering to a few concepts that can't be deviated from or falure will occur. For the moment, forget the 30-50 inch continous blacksmith weld that is required for one tube, and try welding the basic lap joint. Without the coal dust and fresh (unburned) ground bone in between the two pieces, to outgas carbon while welding you will get a "cold weld"...Cold welds are where most failures occur. Probaly by not removing all the scale before welding. If you adhere to time tested techniques, like applying the bone to the surface to be welded directly from your sieve, there is little chance of a bone chunk causing an inclusion the way residual scale will. Even if you apply too much bone in one spot, it simply burns off. I spent several years during and after college on the edge of anvil

WOW!!! Great wootz links...is that true taht some wootz steel can exeed 20% [Brisa link]? I find that VERY hard to believe...Wiki says 2% not 20%...and I'm shocked to see hyperbole on that wikipedia page and links.

.

One of the wiki links has an article about, what used to be called, the DSRT damascus steel reseach team...somewhere in the attic I have a picture of those guys from the 1980's...

.

Oh yeah...the one thing not covered on those pages, so perhaps it's not correct, is how damascus steel got it's name. Under the heading "Origin of the Term" it offers only one plausable explanation and cites several others, but doesn't list the long accepted version that the first carbon steel billets or cakes came from merchants who traded out of Damascus Assyria. Worldwide people began to associate those "cakes" with Damascus [the city] despite their true origin on manufacture. Much the same that we call all reciprocating saws "Sawsall" or an adjustable wrech a "Cresent Wrench", no matter who made the saw or wrench... Water pump pliers we call Channelocks.

.

Simply stated, the misnomer of damascus spread before the knowledge of true origin.

Drew,

I was disapointed to find that something in my gunroom corner where this gun has been stored till it gets its renovation has really turned the colors dark. Even with bright sunlight this was the best I could do.

The gun is an Ithaca Flues, Grade 1 1/2 with 28" barrels.

Thanks Mike and the pattern is nicely demonstrated in that pic. Did Ithaca call that 'American Flag' damascus? It looks alot like the 'Bernard' pattern I posted on the top of p. 3. What year production?

We'll get it added to the PictureTrail and thanks again!

I have generically heard it called 'American Flag' but I don't know if Ithaca used that terminology. 'Etoile' is I believe the correct name for this pattern.

Walt ????

I'll try to get a picture tomorrow when the sun is overhead. It was on the horizon when I took these pictures and I had a hard time keeping my shadow off the barrels.

Per the list on this site it was produced in 1912.

Mike

PS Your page three is not my page three. It depends on your settings of posts per page.

Thanks again Mike. This is Pete M's Remington (again) which is an excellent example of a "Star" or "Etoile" pattern-and I agree they are certainly similar

Drew,

Just a quick note. I pulled that picture off this site at some time. I could only wish to own a Remington that nice.

Pete

I think the additional 'stripes' in the example I posted are the reason for the 'American Flag' name but they are both versions of etoile.

Here's a late 1860s Laminated steel barrel on a nice Scott BL. I think at that time, the British laminated steel was of the highest quality. I think the finish on these barrels is the original from the Scott Factory.

Very interesting Daryl. The rib is clearly twist, but the brls look like the 'Damascus Higny' or 'Damascus Leclere 3rd quality' illustrated on the Higny poster

http://www.littlegun.be/arme%20belge/artisans%20identifies%20h/a%20higny%20gb.htm Probably a 'One Iron Crolle' variant.

(I'm glad someone other than me has nothing better to do on a long Memorial Day weekend than to 'talk' about guns and damascus barrels

)

Here are a couple of rather severe plain twist barrels from the muzzle-loading era. The first is by James Patrick, the second John Blissett & Son. Both British makers. Bill

[url="http://www.hunt101.com/?p=473746&c=500&z=1"]

[/url]

[url="http://www.hunt101.com/?p=473747&c=500&z=1"]

[/url]

Nice William-have they been re-finished and who did the work?

Here are the barrels on my Daly

Barrels on my Miller and Val Greiss O/U combo hammer gun 16ga/9.3x72r

Barrels on my S Sutherland (GH Ferris pat)

Pape 16ga

Revdoc, there may be a similar look, but consider that the British Laminated was one of , if not THE best, of that period. I believe it was best in the tests often reported , was it by Greener ? Now, when we think of Belgian Laminated, we take a step back, as it is usually the lowest grade offered and on the lowest grade guns. I think you will find a different quality in the British Laminated Steel. I also see laminated steel on P. Mullin guns of the same period. His guns sold for up to $300, when that would almost buy a house with servants. Of course, his guns originated in Birmingham and he finished them to the very highest level, but with no engraving.

You are correct Daryl: From Dr Gaddy- "The top barrels in the famous Birmingham Proof House destructive tests in 1891 were three-iron British Laminated Steel barrels. Laminated Steel barrels were made the same way as Damascus barrels but had higher (usually 70% ) high quality steel in the composite." Unfortunately, his damascus barrel board did not include an example of 'British Laminated.' I already added that pic to the PictureTrail and will correct the caption and thanks!

Revdoc, we see lots of Damascus samples, laminated samples, twist samples, then take these and multiply them by the number of various sources. It all gets confusing, but to my , admittedly engineering trained mind, it would be wonderful to have an article that showed all these barrels, from all the sources, side by side. Maybe you could do an article for DGJ or similar ? Now, I don't know if writing is your interest, but maybe someone could pick up this gauntlet and do a broadranging article with good photos from each era and source.

It's also clear that 'reading' the damascus pattern requires knowledge of the grade of the gun.

Thanks for the encouragement Daryl, but a. I'm not that smart yet and b. almost all the pics on the PictureTrail were 'borrowed' from internet auction sites, pics from threads on gun forums (PGCA, LCSCA, here, etc.), and pics sent to me. I have not scanned nor posted any pics from books, but probably do have some legal exposure nevertheless. I'm comfortable putting the pics up, in that I have no commercial interest in the PictureTrail, they came from the 'Public Domain,' and civil action against me would cost more than it would accomplish (I hope!)

Anyway-my intent with the PictureTrail was to provide a resource, and thanks to Dave Miles and others, I'm most thankful the some of Dr Gaddy's contributions were not lost. Hopefully, Dave will add some of these threads to the FAQ section (and we've e-mailed about that.)

Revdoc - The Patrick and Blissett barrels have both been refinished. I did the work, myself, following Dr. Gaddy's procedures in the DGJ.

Bill

Another example of Star Damascus, this time on a Daly. Not sure where I found this image...

Pete

REB87...What? ...AF touch mark on Liege barrels...marked S Sutherland...on a George Ferriss patent...??? Is that correct? It is rumored that George went to France...possibly something to do with Ferris wheel...but that is the wrong George Ferris..

.

the George Ferriss that was issued pat # 119834 is spelled with double s...Ferris (wheel) is single s

.

It's not that I don't believe you, it's just that the Belgians would rather leave the name off of the gun, than pay royalties to some New York Yankee.

.

A couple of years back on this bullitin board system, several members chatted it up over some Belgian made double that was made on Lefever patents...I say "bull"! Either that gun does not exist, or perhaps it's a converted Belgian muzzleloader from back in the days when Lefever was converting muzzle loaders into breech loaders like the Barber and Lefevers..

.

I can see the patent Ferriss breech on your barrels, but with an August Francotte touchmark, I guess it's possible, as Francotte seemed to be one of the few Liege makers that paid royalties rather than just make an improvement on other designs ,giving them a means of circumventing the original patent,like the Deforney Holland ejector system.

.

If your gun is in fact made on a George Ferriss patent, it belongs in a museum. If it's originally made that way ,and not converted, with ANY Ferriss markings, it should probably be in the Liege Arms Museum...so...I'm guessing it's a converted gun or a Belgian design rip-off (post 1871) only because the gun seems to be too good (interesting) to be true...which is it?

.

Utah...your Flues 1 1/2 barrels are exactly the "stars and stripes" pattern known as American Flag Damascus...American Flag Bunting Damascus would have been a more accurate description, but since everyone knew what bunting was back then, there was no need to include the word. Bunting was popular back then, it's relatively rare today...

.

OK ...it's not the patent breech that I first thought, but wow, that gun still belongs on a museum...I thought you had an example of the cap lock breech loader as can be seen in patent 119834...Geo Ferriss had many patents, but none that I have are on on that date...Rather than sway anyones interpretation of your photos along with the proofs and touchmarks, I will just show the two shotgun patents that I have and hopefully many observant eyes will result in an accurate understanding of this extremely unusual double...This gun deserves it's own thread. Even if it stalls for months 'til the right bits of Belgian data surface..That MG brevete number on the action flats will probably corresponde to that patent date. Maybe that patent will answer some questions. More likely, it'll create more questions...I'll try to run it down..

.

I can't help but wonder about the Belgian connection...Did George try to market his design abroad, like Browning and Newton did, or was he already connected to the Belgians because of his ordnance designs?

Some damascus data to follow shortly

Pete M- I think Doug Mann posted that Linder Daly and labeled it "Truk (Turkish) Extra" Looks to be maybe SIX Iron Crolle with a "Star" pattern. Very high quality damascus.

reb87- I added your S. Sutherland laminated steel brls to the PictureTrail (next to Daryl's W&C Scott) and thanks! Is it c. 1880?

William- VERY nice job on your brls!

and Robert- thanks for explaining the 'Stars and Stripes' bunting pattern!

In my opinion damascus steel, as with all other alloys, has never reached the degree of sophisication as it has in recent decades [except for maybe the high art of the Prince Phillip, Remington, or Terrell type damascus]...Well here are some leads for anyones American damascus files...

.

In 1937, there was a company in Rockford Ill. by the name of Damascus Steel Product Corporation. They held a patent for a meat cleaver, but that couldn't have been their only product...Of course 1937 is very late for damascus barrels...

.

In 1856, John Nevill and Lemuel Curtis recieved a patent for simplified damascus substitute [alloy] assigned to J P Farrar of the "Damascus Steel Manufacturing Company"...kind of early for the golden age of double shotgun production, but none the less, another lead.

.

Warner is from New York City

The Sachs technique or something similar has been seen on a high grade Parker

.

There are several more damascus shotgun patents to be shown in the next weeks...sorry they're difficult to locate because they are pre- personal computer files...

Here is a pic that John Mann (I think)sent me some time ago. The second pic is my Clark and Sneider. It just started sprinkling rain when I snapped the pic.

In 1856, John Nevill and Lemuel Curtis recieved a patent for simplified damascus substitute [alloy] assigned to J P Farrar of the "Damascus Steel Manufacturing Company"...kind of early for the golden age of double shotgun production, but none the less, another lead.

The Sachs technique or something similar has been seen on a high grade Parker

There are several more damascus shotgun patents to be shown in the next weeks...sorry they're difficult to locate because they are pre- personal computer files...

FRANKLIN BROCKWAY WARNER

Patents:

818802 - DUST CAP AND SOLAR EYEPIECE FOR TELESCOPES

1181704 -BARREL FOR SHOTGUNS AND RIFLES

1167233 - MANUFACTURE OF BARRELS FOR SHOTGUNS AND RIFLES

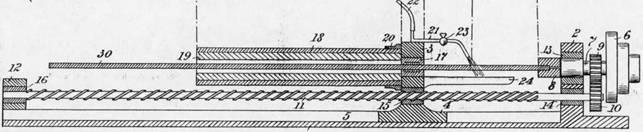

Interesting description for 1,167,233. He was trying to fix the problem of corrosion caused by early nitro powder. His solution was to leave the mandrel in the damascus tube then bore out the mandrel. This gets referenced years later by E.R. Shaw for a patent they filed regarding barrel inserts.

GUSTAAY ADOLF SACHS

Lived in the Dakota territories, then moved to Eugene Oregon.

Patents:

353432 - BREECH-LOADING FIRE-ARM

410678 - METHOD OF ORNAMENTING GUN-BARRELS

495639 - BREAKDOWN BREECH-LOADING GUN

523130 - EJECTOR FOR BREAKDOWN GUNS

674284 - BREECH-LOADING FIREARM

759637 - BURGLAR-ALARM

The Sachs patent essentially engraves a twist pattern on a barrel. A novel approach to faux damascus.

John Nevill

Issue date: Dec 9, 1856

16214 - IMPROVEMENT IN MAKING CAST-STEEL

He claims to describe a method to convert wrought-iron to cast steel.

http://www.google.com/patents?id=K81UAAA...is=1857#PPP1,M1George H. Ferris

Patents:

118849 - IMPROVEMENT IN CARTRIDGE-LOADERS

119834 - IMPROVEMENT IN BREECH-LOADING FIRE-ARMS

246108 - CANNON

Here's a couple for you Robert:

James R Bradley and Moses D. Brown of Chicago, IL

72162 - IMPROVEMENT IN THE MANUFACTURE OF STEEL

Issue date: Dec 17, 1867

Reinhard-Mannesmann of Remscheid, Prussia

365482 - PROCESS OF ROLLING DAMASKEENED RODS

Issue date: Jun 28, 1887

Filed in Germany, England and the USA

WILLIAM EOSE of Halesowen, England

39174 - IMPROVEMENT IN THE QUALITY AND ORNAMENTATION OF METALS

Issue date: Jul 7, 1863

Pete

Thanks...I didn't have the Mannesmann patent...Bradley and Eose didn't have drawings to post pics of...but I really want to thank you for getting the ball rolling on American made damascus. In the past, damascus experts rejected any notion that other than "uncle Bob" (or someone) at Ithaca, damascus simply was not produced in America. In fact damascus steel, the earliest available form of carbon steel, was produced to some degree, in nearly every industrial nation.The information you've posted points to the the real truth about damascus actually being rolled rather than forged since c1880's. In the past at this BBS system, that kind of information, that flies in the face of common long held beliefs, could have got you a gang bashing here. Everyone took Greeners forging information and used it as a corner stone. I seriously doubt that any of the post 1890 barrels were forged. I'm guessing that post 1890 barrels make up 95% of the damascus doubles out there. It's been a long time since I read the Eose patent, but I think rolling damascus weighed heavy into it, and that was 1863..

.

It's hard to believe that most of these guys actually think that a team of 3 Belgian Elves, working for Lochet-Hebron, worked for days hand forging each tube, as pictured in Greener's book. Yeah right! Then they added shipping to America where the workers at Ithaca Gun Co, knit the barrels together, built a gun around them, the sold it for $40 retail.

.

Most of damascus barrels that we see were machine wound onto a negative draft mandrel, and rolled off the assembly line like hotcakes. [no pun intended...wootz cakes] Probably some of the, stubborn about tradition, Brits, continued to hand forge a little later but it wasn't Greener.

.

Pete, one last thing...about your last post...it's made up of highly concentrated data that leads directly to volumes more information. The problem is, all the hours of work it takes to construct such a posting is lost once the thread dies. Had you printed it, photographed it and posted the image, readers could save your entire post as 1 image. This way, your hard earned posting would never die and have a better chance of getting into the hands of the next researcher. With all the time you've already spent, I don't feel right about asking for more. I was just hoping that some future researcher could stand on your shoulders for a better look....

Bob

reb87: Thanks so much for graciously sharing these (high quality) pics-which'll be added to the PictureTrail

http://www.picturetrail.com/gallery.fcgi?p=999&gid=16082038

http://www.picturetrail.com/gallery.fcgi?p=999&gid=16082038Schaefer- Is that Wm. R. Schaefer? Rose pattern Bernard?

Whitney Safety Fire Arms Co. with the grip safety lock- Two Iron Crolle?

Spencer- Is that Spencer Arms Co. or Lancaster-Spencer? another 'Stars & Stripes' American Flag? To my eye it looks just like the Flues 1 1/2 that Mike posted.

Is that about right?

I don't have much trouble understanding how the "irons" or composite rods could be sized, thinned, stretched between rolls. How precisely are the edge welds achieved once the spiral is on the "negative draft mandrel"? Is there an unstated suggestion here that somewhere in the northeastern U.S. existed a powered hammer akin to a predecessor of the Rotoforger which Ithaca used on the steel billets for the 37. Different ends here I admit. If the output of Belgian hammer jockies wasn't up to he demand, where's the equipment or the record of the equipment that replaced them? The patent drwg of the faux applique machine is interesting. Where's the drwg of a machine that could make the real McCoy?

jack

I've followed this thread with some interest. I would like to suggest that anyone that is interested in damascus steel try to get hold of a copy of "Damascus Steel" by Manfred Sachse. I am unaware of any book that covers the subject more throughly than this one. The copy that I have belonged to Oscar Gaddy and I purchased it from his wife after he passed away.

I'm not sure whether it is possible to scan and post some of the pictures that are in the book but I believe that the information in this book may clear up some of the questions about damascus manufacture.

Rabbit, I wouldn't mix in hammer forging just yet...and if you really want to understand barrel damascus, try to avoid the overwhelming volumes of blade technology {which is mostly forged}...the reason the mandrel had negative draft (slightly tapered) was so it could be removed easily.

.

Reb87...about your Spencer...there are several different names associated with that design...The "Norwich" and Torkelson are just two...hopefully someone, who lives near Norwich or Worcester Connecticut, will take the time to sort out the evolution of the Norwich gun...somewhere I have a Torkelson that is very similar to your Spencer..seems To me that Torkelson was associated with Iver Johnson, John Lovell, Andrew Fryberg, and Martin Bye among others. The evolution of the Norwich or Worcester gun has yet to be roughed out, let alone examined closely...

I'm not sure whether it is possible to scan and post some of the pictures that are in the book but I believe that the information in this book may clear up some of the questions about damascus manufacture.

Before this slips to far down the page. Doug please scan and share!!

Bob, I can't imagine why the edge welding method would go out the window simply because the master and his gang aren't fast enuf. Hammers can't be ganged, made into shaped swages, powered by hydraulic ram? How precisely would these strips be welded if not by pressure? Surely you're not suggesting heliarc in 1863. As for "negative" draft, if you had been around patternmaking or toolmaking for any molding or casting trade, you'd know that there is just draft (taper). Never heard the word negative used in the several years I spent around tooling for hand-laid fiberglass and vacuum-formed plastics. The only context I can think for the concept of positive and negative is in the relationship of plug to tool to final product.

jack

Edge welding didn't go out the window...you can't make damascus or twist tubes without edge welding...and whats all the talk about rotary hammers and heliarc? I guess I wasn't specific enough when I said don't mix in "hammer forging" referring to Ithaca's rotary forge that's 50 years later than the period of interest here. Hydraulic rams? trip hammers never had hydraulic rams? You've lost me...

.

Edge welding can be easily achieved with heat, pressure, and borax...impact is not necessary, it's just another way of delivering pressure...

Spencer 1882 pump. The Barrel is damascus and the tube magazine is twist.

Bob,

I have seen Forehand arms and Hopkins Allen shotguns that look exactly like this one(spencer). Ill have to dig out my Torkelson and compare them.

Ross

I didn't use either the word "impact" or "triphammer", Bob. In fact if you look closely, you'll see that I used the word "pressure" which can be applied, as you say, by the momentus momentarius or the squeezus sustainus ha ha ha ha. Indeed the RotoForger may not be in the line of descent from whatever method and mechanism you're suggesting. What is? Hollow ram on the end of the mandrel that bucks up the edges of the spiral. Cmon, what ARE YOU talking about (in specifics of course)?

jack

I don't have much trouble understanding how the "irons" or composite rods could be sized, thinned, stretched between rolls. How precisely are the edge welds achieved once the spiral is on the "negative draft mandrel"? Is there an unstated suggestion here that somewhere in the northeastern U.S. existed a powered hammer akin to a predecessor of the Rotoforger which Ithaca used on the steel billets for the 37. Different ends here I admit. If the output of Belgian hammer jockies wasn't up to he demand, where's the equipment or the record of the equipment that replaced them? The patent drwg of the faux applique machine is interesting. Where's the drwg of a machine that could make the real McCoy?

jack

Jack,

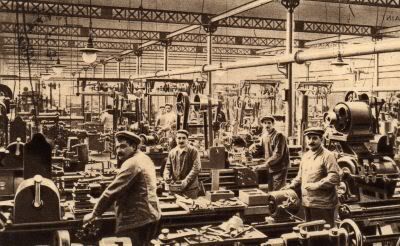

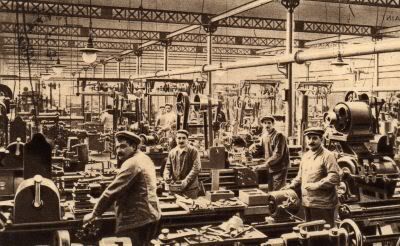

Good questions. From my very limited understanding in reading some of Claude Gaier's work. The relationship between the US and Belgium can be traced back to the American Revolution. (Belgian Gunmaking and American History by Gaier.) Gaier notes the huge volume of firearms destined for American shores after the revolution began. We are aware that during the American Civil war there were official and some not so official observers from Europe. One of the lessons that the Belgians took home was the impact of mechanization in the making of firearms. Several companies took this to heart. Gaier points to FN and Pieper as taking up the "new way" of using factories and machines. ("Quatre siècles d'armurerie liégeoise" by Gaier. Also "Les hommes, les armes et les machines du Chevalier Pieper & Cie 1859-1957" by Michel Druart.) This was stepped up over time. We like to think of a Belgian cottage industry in sporting firearms. This was also true. Gaier notes the there was almost a class hatred between the cottage firearm maker and the factory worker.

I stated all that for a reason. I have pictures of both methods. The end of damascus production in any reasonable volume was some time in the 1920's.

Since the formation of the EU all patents are now under one authority. I have tried to use their web search engine to find exactly the sort of patents you are asking about. Unfortunately, my attempts are futile and frustrating. There is something I am not getting, but the results are always worthless. I guess, I should start trying to pry that information out of the American patents. You are correct, some one was making these machines. If we can identify an American source and date it, we are closer to understanding.

Also, Robert's caution about damascus for blades is correct. It is a different product. Which is why I did not attempt to track that Rochford reference above.

Pete

I've followed this thread with some interest. I would like to suggest that anyone that is interested in damascus steel try to get hold of a copy of "Damascus Steel" by Manfred Sachse. I am unaware of any book that covers the subject more throughly than this one. The copy that I have belonged to Oscar Gaddy and I purchased it from his wife after he passed away.

I'm not sure whether it is possible to scan and post some of the pictures that are in the book but I believe that the information in this book may clear up some of the questions about damascus manufacture.

Doug,

Please do post some. If any one is looking for this book, it was published in German and English. The English version is difficult to find. There is one up on eBay now.

http://cgi.ebay.com/GERMAN-DAMASCUS-SWOR...8QQcmdZViewItemI am not connected to this auction.

Pete

Oh I get it I guess. No American damascus barrel production (my mistake) but immense secrecy in Belgium to hide the "new ways" from their own Luddites/labour protectionists. Must have succeeded since there appears to be an entire mechanized industry which never happened.

jack

My next Model 12 project gun will have a Damascus magazine tube. No worry about blowing up the gun, and a legitimate "new project" for Sherman Bell. "Are Composite Magazine Tubes Safe with Smokeless Loads?"

Rabbit, There were damascus barrel makers in America, but very few...relatively none, when compared to Europe and England...during the hey-day of American double production it seems as though not one American damascus maker could not compete with the Europeans makers in both numbers or cost..American makers chose the fluid steel alternative, as the Europeans eventually did.

.

Also

.

Didn't all heavy industry, in Liege, crash during WWI or WWII, or was Liege spared?

.

.

Although I have no saved proof to offer, I was told, that after WW II, a few Val Trumpia gunsmiths (desparate consumers of Liege forgings) bought out Manufacture Liegeois's drop forges, dies, or fixtures. Shortly afterwards, the Val Trumpia double shotgun production numbers climbed like never before while the Liege smiths re-tooled.

.

If the Liege sporting gun industry wasn't interrupted during WW II, why then would the Italian gunsmiths be so desparate as to buy their tooling?

Since the formation of the EU all patents are now under one authority. I have tried to use their web search engine to find exactly the sort of patents you are asking about. Unfortunately, my attempts are futile and frustrating. There is something I am not getting, but the results are always worthless. I guess, I should start trying to pry that information out of the American patents

Pete

.

Pete...If you could narrow it down at the US patent office, there will probably be a European classification number to cross reference...But I won't waste my time on such a pursuit...I've been searching for years for any related patent to the venerable Belding & Mull without success. There are more dispensing and metering threads than I can view. The machinery patents that you seek could be buried in any number of classifications with all the various sub-catagories or threads. Could be in a winding thread, could be in a seam welding thread, or it could be in a manufacturing process thread. It's probably in several threads. But who knows...you might get lucky by patent searching the names of known makers of damascus/twist steel. If that doesn't work, it's going to be hard row to hoe. Maybe Gaier's book will offer some search names...Bob

There were damascus barrel makers in America, but very few...relatively none, when compared to Europe and England...during the hey-day of American double production it seems as though not one American damascus maker could not compete with the Europeans makers in both numbers or cost..American makers chose the fluid steel alternative, as the Europeans eventually did.

I think part of this has to do with profitability. If you are going to start making barrels, then you will be looking to the rifle and hand gun markets as well. From at least 1890 to 1920's American policy implemented a series of tariffs on imported goods. So, the Belgians, English and German barrel makers had to be offering a unique / affordable product. In addition, makers like Heuse had American agents competing for business here.

Didn't all heavy industry, in Liege, crash during WWI or WWII, or was Liege spared?

From the little research I have done. After WWI there was a great outcry about German atrocities in Belgium, mainly forced labor. I do not believe the factories themselves were damaged. After WWII the a lot of the heavy industry of Belgium was damaged by Allied bombing and the ground war that ensued. So there had to be a major rebuilding effort.

If the Liege sporting gun industry wasn't interrupted during WW II, why then would the Italian gunsmiths be so desparate as to buy their tooling?

The Italians were in even worse shape after the war. A lot of damage was done during the German retreat and again the bombing campaign.

Hopefully, some one with more detailed knowledge of this period will respond.

Pete

Pete...I know nothing of the import tariffs but this....and I am reluctant say this, as it will surely be interpreted as "fighting words" by some...but here goes...

.

Back in the 19teens an immigrant Austrian apprenticed gunsmith by the name of Fred Adolph of Genoa and Rochester New York imported Austrian and other high grade guns into America. He advertised that he made the guns to cover the fact that he was in fact importing the guns in pieces in order to skirt the import tariffs. Because of the Fred Adolph stories, and the fact that his close personal friend, Chas Newton (a lawyer and owner of Newton Rifle Corp.), also tried to follow suit as a barrel importer for his own factory, I think barrels (and parts) were exempt from any stiff tariffs...I can elaborate on the Newton barrel importing effort if you would like.

.

As for the Italians being heavily damaged, maybe the Val Trumpia region was spared becuase of it's location away from the shores, way up north. By the way...I was told that as a general rule (not always), you can locate family origins by the last vowel. Families whose name ends in "o" or "a" are from sothern Italy (traditionally)...Family names that end in "i" are from the north, like Bernadelli, Zanotti, and Beschi...just in general though

Back in the 19teens an immigrant Austrian apprenticed gunsmith by the name of Fred Adolph of Genoa and Rochester New York imported Austrian and other high grade guns into America. He advertised that he made the guns to cover the fact that he was in fact importing the guns in pieces in order to skirt the import tariffs. Because of the Fred Adolph stories, and the fact that his close personal friend, Chas Newton (a lawyer and owner of Newton Rifle Corp.), also tried to follow suit as a barrel importer for his own factory, I think barrels (and parts) were exempt from any stiff tariffs...I can elaborate on the Newton barrel importing effort if you would like.

The tariffs started out as a protectist move for the American farmer. They had the opposite effect. McKinley gained national recognition with his 1890 tariff. The tariff wars in Congress raged for almost 30 years. The actual tariff rates and those items on the list changed back and forth. I believe that the barrel tubes incurred 1 rate, while finished barrels a higher rate. One of Wilson's campaign planks was to do away with the tariffs, which to a certain extent he did.

A Puck cartoon attributing the Republican defeat to the McKinley Tariff. With McKinley as Napoleon leading his troops out of Russia.

I am surprised there aren't more stories about "black market" gun parts. Yes, what more do you have about Newton.

Pete

I like to think that I have the most of the big picture when it comes to the the evolution of the Newton barrels. I've been a long time wildcatter, shooting a .220 Dean (blown out swift), .256 Sabad (Vom Hofe), .30 Reis, .256 Newton, and I recently acquired a ".30 Nedgley" barrel by Neidner Rifle Corp. but I haven't started on it yet. The area where I live is wildcat country, maybe because of Newton's influence on local interests, but whatever the reason, Western New York has been the home of well over a dozen wildcats. Most notably the 25.06 (.25 Newton to .25 Neidner to 25.06 Rem) .338 Winchester (.33 Newton with a belt) and 6.5 06 (.256 Newton)

.

That being said, it's important to note that Newton abandoned the .25 caliber bullet for the 6.5, not because of the liability of the .25 getting into the wrong guns as some have suggested, but because Mauser, Steyr, and Sauer where already tooled for 6.5. ... WW I, and the tremors that led up to it, created enough difficulties, that ultimately Newton changed horses mid-stream and abandoned importation from Mauser and Sauer, and just imported a rifling machine from Steyr (in 6.5). The machine arrived in several shipments of parts and upon assembly, no one could get to work correctly. In a letter to Newtons investors, he explained that one of his large expenses was the high cost of paying his "model maker" (Emil Flues) to work exclusively trying to make the machine work. After months of wrestling with it, Newton brought in a barrel expert (Harry Pope) to work out the remaining kinks...which he did...and to this day, if you know what your looking for, you can still buy a Newton rifle, hand finished by Flues with Pope rifling.

Oh yeah... I have the remains of Harry O Dean's files and unpublished manuscripts...He was a gun writer for several gun magazines after WW II ...and big Newton enthusiast/researcher/writer and for what ever the reason he was also photographer for Marlin, Ithaca, Savage Fox, Crossman and others. I got the manuscripts and negatives, but unfortunately all the factory photos were stolen by Joe Reece and the "high tech burglary gang" along with Charles Newton's personal Austrian drilling marked Fred Adolph, Genoa New York. The gun can't be missed as it has a gold C N cypher where the top lever should be. There's a picture of the gun in his files. They stole Harry's entire collection from his widow a few weeks after he died.

Many thanks to those of you who suggested Keith Kearcher to my younger brother. His Greener G60 (he found the grade marking not on the trigger guard but on the fore end iron) just back today from having had his barrels refinished, sighting ivory bead replaced, ebony diamond insterts restored, stock glass bedded and action tightened up. Keith measured the minumum bore wall thickness at .035. I think this one will be a good shooter for many years to come.

I'll leave it to my brother to post more photos, here is a photo of his damascus. Keith turned the gun around in record time (under 4 weeks). I think these barrels are the highly prized three iron. My brother just got the Greener book and wonders if these are the silver, stub, or other version of Greener's damascus.

Kearcher would certainly know, but they look like high grade Bernard. When was the Greener made?

Rev-

Thanks. Another member based on the SN dated it to the late 1880s.

Doug

Robert- that's where the quote on the 'Damascus Barrels' PictureTrail album intro page originated

"These fine barrels are not worked and twisted so neatly and nicely that they may look beautiful alone, but rather for the reason that greatest lightness, combined with greatest durability, may be produced." (from the 1899 Parker Bros. catalog)

I'd like to add a few more interesting/meaningful quotations if anyone has a good one.

rev...sorry to re-hash ground that has already been covered...I was hoping to have something new for you...

.

not that these qoutes will relate to your damascus picture trail, but they have always been my favorites...

.

taken from a sign in Harry Pope's shop

"If you must know when your gun will be done, the answer is now. Take it when well done, or take it elsewhere"

.

then this not so good gunshop sign

"Gunsmithing is a lot like oats. Premium oats will command a premium price, but oats once through the horse do come a little cheaper"

The white is iron and the dark is steel. Did we not decide it was opposite just the other day?

Yes, the Parker catalog was one of the sources of my original confusion-but per other sources, Dale Edmonds, and Dr Gaddy- it's IRON turns BLACK and STEEL turns WHITE.

So does it stand to reason that the barrels with the most steel (white swirl) in them are the superior barrels and thus, the percentage of white the barrel, a fair indication of the quality of a damascus barrel; or is there anything good about having iron in a barrel?

It would appear that in the Greener photo I posted above, there is a lot of steel in those barrels (is this an example of the famous 70% Birmingham damascus...actually it looks like it might have a bit more than 70% white swirl)?

On p. 380 of 'L.C. Smith "The Legend Lives"', the damascus barrels as graded by Hunter Arms are shown, and the steel % described as follows:

English Stub Twist- 52%

Good Two Rod Damascus- 60%

Good Four Stripe Chain Damascus- 60%

Fine Three Rod Damascus- 67%

Finest Three Rod Damascus- 70%

Choice Three Rod Herring Bone Pattern- 70%

The Greener brls may be 'Bernard', which was available in several grades. Please see Ferdinand Drissen's 1897-1898 price sheet:

More notes on American damascus if anyone is still interested

.

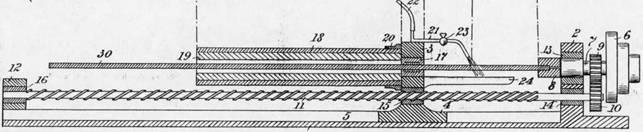

In early 1864, Walter Baker of Ilion NY (very near Lisle NY. then home of W H Baker, but I don't know if they're related)recieved a patent for a trip hammer that was specially designed for making gun barrels (patent 41669)...one of the reasons I'm mentioning this patent, is to show the tail end of hammering, and that by the late 1860's the shotgun industry had already adopted the higher volume production techniques. I am hoping that the thread contributor with access to the Tompkins County directory will cross check the name of Walter Baker, to see if he appears anywhere near Motts Corners (prior to 1863). I'll check Jerry Swinney's files for the same.

.

In 1865, Ethan Allen recieved a patent for twisting, winding, and welding damascus shotgun barrels. The patent, 48249, goes into details of the process. One the witnesses is Sullivan Forehand. Then, exactly one year later Ethan recieved another patent for soldering the tubes together through internal flaming. Again Sullivan Forehand was a witness. Ethan Allen resided in Worcester Mass at the time of both patents

.

In 1869, a patent was issued to Selah Hiler of Harlem NY for improvement in the manufacture of gun barrels in which he states that "sucessive rolling operations" is the "usual" (manufacturing process) (by 1869). This is not the only reference to the rolling of damascus shotgun barrels in the historical record, but it is the last time I will spend trying to convince the guys still holding onto the thousands of hammering elves concept. (samurai barrels)

.

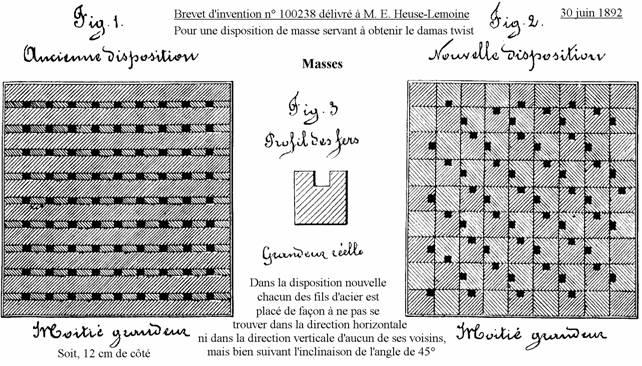

Lastly, although this is not for American made damascus, I thought that you might be interested to know that winding was not the only technique used for making damascus barrels. In 1892, Franz Meixner of Austria recieved a U.S. patent for a new departure in damascus barrel making that involves many cones stacked around the mandrel. This technique offers a much higher surface to surface area for welding, and theoretically offers a far stronger damascus barrel than anything seen before. (US pat 477763)

I hope I'm adding to the understanding and not inadvertantly adding to the misunderstandings involved with damascus steel shotgun barrels...Please note how the great missing chapter of American double evolution keeps cropping up ...Worcester

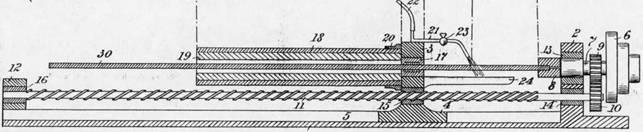

Here's a copy of Ethan Allen's damascus patent. I decided to post it only because it's a very interesting read. Please say if this data is overly technical.

Walter Baker is 33 in 1870. Born in England and works in the armory. He lives in German Flats, NY with his wife and 4 children.

William H Baker is 44 in 1880. He lives in Manlius, NY with his wife and 7 childern, the youngest a boy named Walter. William H Baker is listed as being born in NY.

Of course, I could have these 2 names very confused...

Worcester is interesting. It is the home of the Bay State gun company which was later purchased by Hopkins & Allen. Bay State used several patents by W.H. Davenport, who later sold single barrel shotguns under his own name.

By the way. Nice work finding the trip hammer patent.

Drew,

I like the price list. I have seen similiar, but never so complete.

Pete

Pete,

You sure nailed it down at light speed. With W H and Walter being only a year apart and born on different continents, I guess it's highly unlikely they're related. Also, Walter's being born in England, makes it unlikley that he ever worked for the dyed in the wool outfit later known as Losey and Lull (in Motts Corners) Thank you Bob

Pete: The Price List comes from the April, 1976 American Rifleman article, and helps a great deal trying to interpret the quality level of the various named damascus patterns.

Rev,

After all this is your topic...and you have taught me 10X more about damascus barrels than anyone...I was hoping that you would say whether or not I'm adding to the understanding or whether I'm being overly technical. I figured that the biggest contributions I could add, is to dispell the erred concepts that damascus was never produced in America and the samurai barrel notion. I hope you see this data as positive advances in the understanding of damascus barrels. If not, just say so and I won't contribute further...Bob Chambers

Robert: By profession and calling, my duty and responsibility is to seek the truth. ANY 'truth', as best we can document and understand, is a contribution to the field of knowledge. Unfortunately, in Medicine anyway, what passes as 'truth' usually changes every few years

Hard to argue with copies of patents however! And your, and Pete's, contributions, and every pic posted with a different damascus pattern, have been extremely valuable.

I believe the book, Espingarda Perfeyta or The Perfect Gun, written in 1718 shows the "cone" method of making Damascus barrels. Of course, not called Damascus then. Interesting a patent for something similar over 150 years later.

In 1869, a patent was issued to Selah Hiler of Harlem NY for improvement in the manufacture of gun barrels in which he states that "sucessive rolling operations" is the "usual" (manufacturing process) (by 1869). This is not the only reference to the rolling of damascus shotgun barrels in the historical record, but it is the last time I will spend trying to convince the guys still holding onto the thousands of hammering elves concept. (samurai barrels)

Robert,

Do you have a patent number for the Selah Hiler patent? I want to read it. Rolling mills became essential for the gun industry. Curious to see if the patent talks about low / high carbon etc.

Your information is very valuable. Do not stop.

Pete

Pete,

Thanks, that means a lot more coming from top quality contributors/researchers like you and Rev. I really admire the way that Rev leaves records (picuretrail) to be added to at any time. His data collection will probably outlive all of us.

.

The reason I didn't post the Hiler patent (34961)is because his patent marks the beginning of decarburized/compressed steel shotgun barrels (1869)...it would be another 20 years before the industry really began to utilize this technology. More to follow...

There seems to be several patents and many records of barrel makers in New York City in the mid to late 1800's. It must have been a sort of "hub" for barrels makers and iron workers.

.

I don't know what to say exacly so again I'll just blurt it out...3 years ago, at this website, I would have been tarred, feathered, and run out of town on a rail for suggesting that not all damascus guns have samurai barrels (in fact relatively few)...but now that the age of ignorance has passed, I have become a fisherman of sorts. I'll explain,...for example...now that Ethan Allen's patent has been posted, I'm waiting for someone to come forward with an early Allen shotgun, where there can be no doubt that it is actually American made damascus....especially if the barrels are dovetailed together completely down the barrel...The other maker to watch for American damascus is Wesson, I suspect his barrels were sometimes American made but I have no evidence yet. Once we learn how to recognize Allen damascus, hopefully we will be able to recognize it if it appears on other guns...thanks again...Bob Chambers

Pete,

If your interested in the demise of damascus, you may want to read 1005115 (1911)...it was issued to Franz Hatlanek of Kladno Austria...Kladno is also the home of Poldi steel including "anti-corro steel" but I have not yet connected Hatlanek and Poldi except for proximity and trade. At the very least, they where competitors if not associates. My guess is that Hatlanek was an employee at/for Poldi. I'm assuming Poldi is also someones last name and not just the name of that large Austro-Hungarian steel producer located in Kladno.

.

also the exclusive horse shoe nail period was 1800 - 1825, after that there were more variations to choose

.

true hand hammered damascus (stub/twist/skelp/mingled), like Rigby damascus (Dublin), became economically unfeasable in the percussion era. If someone thinks they have a hammered damascus gun, it had better be percussion or a converted percussion (like Barber & Lefever)...past that, you better have documentation that shows that maker (or makers supplier) was still hammering so late. The only breech loading exceptions that I have seen had high relief Rigby damascus recievers and rolled damascus barrels. Both were Irish guns.

.

True Damascus steel (capital D) better known as "wootz" actually originated in Kurdistan. At least that seems to be the general consensus. Perhaps Rev already stated that, and I'm re-hashing old ground.

.

Does this BBS have a spell checker?

HJ,

I think Bob is referring to the very early breechloading Ethan Allen shotguns(which I dont have an example of yet) that had a hinged breech cover that opened to the side and used the triggerguard (I think) like a lever to extract the cartridges.

RC - excellent research - keep going!! For sure I enjoy hearing what you find out.

Reb I knew the gun wasn't in the time frame...I just posted it because of the Damascus pattern.

This is a c. 1870 Ethan Allen-sure would be nice to know if this is British Laminated or 'home' made

I have two, and have had several other Ethan Allen trapdoor shotguns. Their Damascus varied by grade. In 1869 they offered Fine Stub Twist on their $100 gun, and Fine Laminated on their $150 gun. A special gun, not serial numbered , was made for G.H. Coates, the foreman of the Allen factory. It's barrels are marked Finest Laminated. These guns are interesting in that the bottom half of the breech of the gun, approximately 2 1/2" wide x 3" long x 1" deep, appears to be made from the same piece of "steel" as the barrels.

The Allen in Hopkins & Allen was Charles H. Allen. Hopkins & Allen was formed in 1868 in Norwich, Conn.

Ethan Allen was from Massachusetts. He was born in 1806 and died in 1871.

Firearm firms associated with Ethan Allen, from Wikipedia:

1831–1837: E. Allen (Grafton)

1837–1842: Allen & Thurber (Grafton)

1842–1847: Allen & Thurber (Norwich)

1847–1854: Allen & Thurber (Worcester)

1854–1856: Allen Thurber & Co (Worcester)

1856–1865: Allen & Wheelock (Worcester)

1865–1871: E. Allen & Company (Worcester)

Pete

1867 Bernard shotgun, decorated by Joseph Boussart from the Liege Museum of Arms

1887 Lefever with Boston damascus, from the Liege Museum of Arms

Drew,

There are a lot more of these images available on-line. Go to

http://www.museedarmes.be/home.htm Click on Catalogue

Click on Base de données du Musée d'Armes de Liège

Click on Connector

Click on Recherche en full text

enter Damas

You will get 26 items.

Pete

Reb87 has brought up a very important point. Ideally an Allen trapdoor double will surface. the words, Patented Nov. 25 1890 has been recorded on Hopkins and Allen shotguns. That date correspondes to patent 441395, issued to Martin Bye and assigned to Sullivan Forehand. Both patent and shotgun were toplevers. Allen died (1871) only 6 years after the trapdoor patent was issued. His successors , Forehand being one of them, continued on with the Worcester gun trade after his death. It would be very hard to concieve that Forehand and the others produced no double guns from 1871 to 1890...surely there were many, but again we are into lost chapter of American double evolution...the Worcester gun...I guess that makes all Worcester doubles suspect, especially the early toplevers (pre1890)...Wish I could be more definitive but I never got around to buying the book by Harold Mouillesseaux about Ethan Allen...maybe that book will yield some information or clues, if anyone has it...I'll take a picture of Torkelson damascus barrels and post it, but I think that's way too late.

You're killin' me Pete

Moire, Bernard, Turc mine blanc, damas turc, Boston and a Purdey-what I wouldn't give for high resolution close up pics of those barrels!! Anyone with lots of class and money hitting the Musée d'Armes de Liège this summer?!

One of the Irish doubles with the high relief Rigby damascus recievers, that I mentioned in an earlier post, is a Joseph Harkom, 12ga, round action,front action hammergun, Jones rotary underlever, straight grip, with what looked like rolled damascus barrels to me. I think the gun now lives somewhere near Syracuse NY. So for good examples of late hand hammered Rigby damascus take a look at the Harkom rotary underlever reciever. There is little to no engraving, but instead the action is 100% high relief damascus.

.

I once bought a caplock T. Mortimer, 20ga, fully engraved, str grip double, with high relief silver damascus barrels and raised proofmark silver soft plugs on top from Dutchman Woodworks for $300...I loved it for a few years and let it go for $375 to a friend from Batavia NY...wish I hadn't...I never knew much about that gun or the origin of the damascus. The main reason I bought it was because it was the only piece of silver damascus I had ever seen.

Unfortunatley, I think the Liege museum is still closed. They have been "refurbishing" it for several years.

Krupp "Nirosta" (patent 1912) is another stainless that may have originated at Poldi. At that time in the company's history, Krupp had enough money to buy anything he wanted like patents and whole armorplate companies simply for the technology.

Early on, A. Krupp's pride and joy was his huge steam hammer "Fritz". By 1864 he had 7000 men using it to make "fluss stahl" barrels amoung other things; by 1871, he had 10,000 men. When "Fritz" failed in the mid 1880's, Alfred Krupp installed a 5000-ton hydrulic press for his now 20,000-man workforce. It was no different in Liege, Gardone, Birmingham, Suhl or New Haven; the industrial revolution had hit gunmaking by the 1860s(It all started with Watt's engine in 1782 and was going "full-steam" in England by 1800). The British need us too, and came to America for mass-production rifle-making machinery from Robins and Lawrence of Windsor, Vermont and Ames Mfg. Co., Chicopee Falls, Mass. With it, they to equiped their arsenal at Enfield. There, by 1858, they were turning out 2,000 rifles a week. (Tate, 1997). Greener, himself, mentions using "17 different machines to shape stocks".

I could'nt help but think by the mid 1860's Damascus barrels were at least partially machine-made--ultimately, a dollar is a dollar; machines were cheaper and more efficient, then as now.

It still takes the touch of human hands to make a good gun, however, now as then!

Sorry for the late addition...this may help someone identify their damascus barrels maker.

.

In 1894 a British patent was issued to Eugene Joris of Fraipont Belgium, who lists himself as a "manufacturer", seeking a patent for a new metheod of manufacturing damascus tubes. He prefaces his patent by stating that "damascus tubes in use up to the present time consists in rolling the steel band into a spiral".

His new patent damascus is comprised of 16 longutudinal rods, without a mandrel, that can be welded by rolling in a press or by hand hammering.

.

the key info is that another damascus craftsmen has been identified including city of origin..the patent number is 1981, it was issued in 1894....And yes, there were still a few stragglers interested in hand hammering well into the 1890's... NOTE...Not to be confused with Belgian gunmaker Jean Joiris of Wandre Belgium...jor not joir

Rocketman,

To quote yourself "Carbon can't be mechanically driven into iron - it must "disolve" in a high heat environment."

I know what you mean, the carbon must be absorbed on a molecular level, but when you're standing there with the tongs in one hand and a hammer in the other, molecular injection is not the model the old timers had you thinkin' about. You layer and sometimes folded (rarely) the carbon (ground bone and charcoal dust) into your separate bars. After welding with heat and hammer, the single massive bar is twisted hot with borax and the remaining slag is driven out using heat and hammer.

Well at least this is the technique I was taught or maybe my perception of what I was taught.(30 yrs ago)

.

Well I could sense that you weren't buying that concept, and it's easy to see why...I'm not in disagreement with you, I just didn't want you to go away thinking that I had my ass on completely backwards...so in defense of erred (maybe) concept, I would like to post his page from a book published by Johns Hopkins University press (1960's)

Maybe you can't mechanically drive carbon into steel, but we didn't know that, so we went ahead and did it anyway...My blacksmithing experiments, unlike my case color experiments, rarely resulted in defeat. Bob Chambers

.

P.S. except for the common beginners mistake of forging the billet way too wide, I can think of no other reason to make longitudinal folds. The longitudinal folding technique allows the smith to concentrate the high carbon area at the cutting edge of the blade (in the crease). Wrong or right, that was the idea. Keep in mind that I learned farm implement smithing, the only kind still in existence in these parts. 100+ years ago, this technique was used when making implement blades out of regular mild steel. Nowadays most steel choppers just run over the cutting edge with some hardface welding rod and grind it sharp, the technology has changed, but the idea is the same.

RC - I have no issue with what you do/did at the forge, only how you describe it. To be effective, the carbon must be exposed to the steel at high enough temperature to chemically combine. By repeated heating, folding, and hammering, you "kneeded" the steel much as one "kneeds" bread dough to mix in a little extra flour. By making the steel flow in the heating, hammering, and welding steps, you exposed a lot of new surfaces to the extra carbon you added. This increased the amount of steel exposed to extra carbon and allowed for a much more uniform alloy. A ten pound bar of iron would need less than a tenth of a pound of carbon added (absorbed) to become a serious high carbon alloy. The trick is, of course, to carbon without burning out the carbon in the surfaces exposed to air.

I have no reservations as to admiration of blacksmithing skills.

Thanks, I knew we were on the same page. I was thinkin'...that you were thinkin'...that I wasted all that time, barkin' up the wrong tree, rather than teaching myself damascus steel making.

.

Did you see that new damascus solid rods are available as raw material for gun barrels and jewelry manufacture(?) directly bubble wrapped from Bombay, India? Some say wootz originially came from India. I've also heard or read Sri Lanca (Ceylon), Kurdistan, Persia, Assyria (nearby to Damascus City), and even Sweden. Is Kurdistan the general consensus?

I doubt there is any hope of proving where Wootz originalted. It would have been widely traded as it was highly desirable stuff.

I'd bet on the re-emergence of barrel damascus - only highly automated.

Verhoeven seems to think Wootz originated in S. India

http://met.iisc.ernet.in/~rangu/text.pdf

Well most scholars from India agree:

http://materials.iisc.ernet.in/~wootz/eritage/WOOTZ.htmhttp://metalrg.iisc.ernet.in/~wootz/heritage/Ind-heritage.htmlI have a couple of books on damascus and it's history, all point to India as the primary source. Rocketman is correct. This was a highly valued trade item.

Hey Robert, a 14" shotgun barrel?

Pete

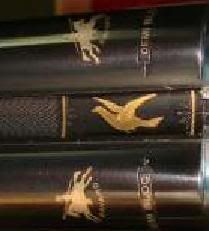

STILL working on the PictureTrail. Have found 3 excellent examples showing 2-, 3-, and 4-Iron Crolle patterns in which you can clearly count the number of 'scrolls' between the 'ribband' weld lines. This works fairly well in "Turkish" and "Horseshoe" Crolle patterns, not so well in others as the weld lines can be difficult to distinguish.

The 'ribband' weld lines are seen clearly in this 'Black and White' refinished Two Iron Crolle pattern. Within the weld is one 'scroll', representing one 'iron' or 'blade', and 1/2 of the adjacent 'iron' on each side. F Grade Lefever:

Three Iron Crolle has two full scrolls with a 1/2 scroll on each side. LC Smith 'Finest Damascus':

Four Iron Crolle:

Three full scrolls between two 1/2 scrolls within the ribband weld lines. Baker Presentation Grade:

Everybody see it?

Best explaination and illustrations I've ever seen. Thanks.

PeteM,

Howdah you know that's the only legnth? When I saw the part that said 51-100 employees, I figured there's probably something bigger, after all it's listed as "for the gunmaking and jewelry trade" ...sorry about the "howdah", from now on I'll leave the double entendre (no pun intended)to the other guys.

.

Rev,

It's probably pointless to say/ask...but...are you a member of the Ohio Gun Collectors Assoc? ..The reason I ask is because the editor of the the original OGCA newsletter called the "Hoss' Thief Gazette" also had a "long sufferin'" assistant editor...thought you might be related.

I second Rocketmans previous post!

Robert: I'm a KS boy, though mostly edukatd at the U. of Mo.-Columbia, and

WAY down the editorial chain in this household

"Horseshoe" Damascus has been mentioned. This is Two Iron Crolle "Horseshoe" on a W.H. Baker & Co c. 1877-1880.

Note the ribband weld lines are a bit more difficult to pick out, but you can still see a more open full scroll with a 1/2 scroll on each side:

Any opinions on the rib marking and pattern on these?

http://www.auctionarms.com/search/displayitem.cfm?itemnum=8035246Was thinking "laminated" and "twist" were same....these certainly dont look like "twist though, so guess I was wrong?

Best,

Mark

Mark: Definitely NOT twist and, though tough to tell from the pics, those do appear to be Laminated Steel (as stamped) which are very high quality damascus barrels.

Now that Oscar is gone, does anyone do an outstanding job on Black & White?