I'm doing a little digging to try and nail down when the CIP countries dropped lead crushers for pressure measurement and converted to piezo-electronic transducers. So far, here's what I know:

Per the Birmingham Proofhouse, they were still using crushers as recently as November 2001. And as far as I know, the Brits continued to mark their guns (12 bores) 850 bars standard proof, 1200 bars superior, until they dropped all proofmarks with an actual pressure number in 2006. Those are crusher numbers.

The proof certificate of a Spanish double from 2001 shows a proof pressure of 1370 bars, which is a transducer number. So the Spanish Proofhouse had converted to transducers by then--but maybe not long before that. (I have a photo of a Spanish 20ga from 1999 which is stamped 1200 bars, which is the old, crusher-derived magnum/superior proof.)

I'd like to hear from those of you that either have guns with pressure figures included in the proofmarks, like Spanish guns or British guns from the "bars" era, if your gun also includes a date code. I'd particularly like to hear from those that have proof certificates on Italian guns, which are only marked with a symbol rather than an actual pressure figure. Specifically, I'm trying to determine when the Gardone Proofhouse switched from crushers to transducers, but I think it would also be of interest to determine when other CIP countries did the same thing. It would appear, from the evidence on British and Spanish proof, that they did not all make the conversion at the same time.

Finally, I'd note that the old crusher figures and the new transducer figures are simply different ways of expressing the same pressure. 1200 bars crusher = 1370 bars transducer, again per the Birmingham Proofhouse. However, if you're trying to convert your gun's proof pressure to psi, you can't multiply crusher values x 14.5. If you do, you end up with lead units of pressure (LUP), not psi. You can convert transducer-derived values, either bars or kilograms per square centimeter, by multiplying x 14.5.

Thanks in advance for your assistance!

Possibly they were doing both for a period of time to gain familiarity and confidence?

Possibly they were doing both for a period of time to gain familiarity and confidence?

Could be. I'd be interested in seeing any evidence along those lines.

A bit off topic...

Larry,

I think you are looking for revisions to the Brussels Convention. These happen on a regular basis. I know they issued guidelines in 1991. Not sure when the latest was.

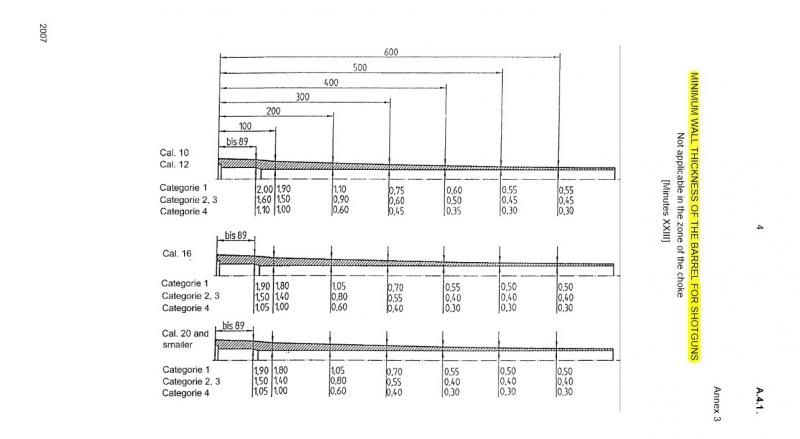

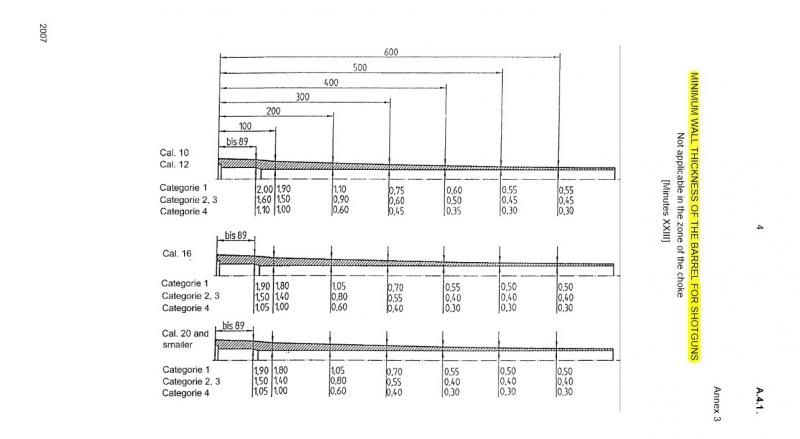

http://www.cip-bobp.org/sites/default/files/new_file/A-4-1_EN.pdfMinimum shotgun wall thickness by gauge and steel category.

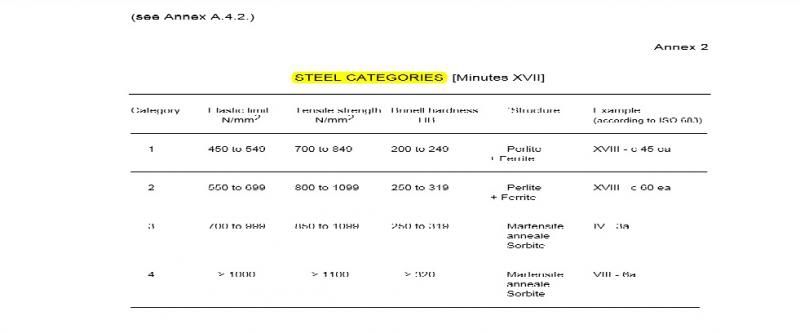

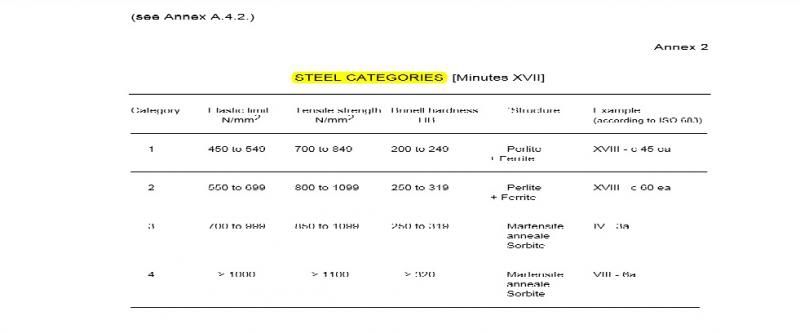

Steel categories.

https://en.wikipedia.org/wiki/Proof_test#cite_note-14

https://en.wikipedia.org/wiki/Proof_test#cite_note-14Under SAAMI proof test procedures, for bottlenecked cases the centre of the transducer is located .175" behind the shoulder of the case for large diameter (.250") transducers and .150" for small diameter (.194") transducers. For straight cases the centre of the transducer is located one-half of the transducer diameter plus .005" behind the base of the seated bullet. Small transducers are used when the case diameter at the point of measurement is less than .35".

Under C.I.P. proof test standards a drilled case is used and the piezo measuring device (transducer) will be positioned at a distance of 25 mm from the breech face when the length of the cartridge case permits that, including limits. When the length of the cartridge case is too short, pressure measurement will take place at a cartridge specific defined shorter distance from the breech face depending on the dimensions of the case.

The difference in the location of the pressure measurement gives different results than the C.I.P. standard

Videos of CIP proof testing

http://www.cip-bobp.org/epreuves%20videoPete

The short version of the CIP recs in American

For 12g Standard Steel................................20g

End of chamber - .079”..............................075”

Past forcing cone/ 4” from breech - .075”.......071”

8” - .043”............................................041”

12” - .030”...........................................028”

16” - .024”...........................................022”

20” - .022”...........................................020”

The wiki article seems to provide a clue, referring to pressure testing prior to 2006. That's an interesting date, because it's also the date of the latest change in British proofmarks. Since 2006, the British proofhouses no longer use any numerical pressure markings, having replaced them with STD (standard) and SUP (superior). But the Spanish proofhouse was using transducer values several years prior to that.

Another possibility is that although some countries (England) continued to stamp crusher-derived pressure values on their guns (850/1200 bar), they may in fact have changed to transducers at an earlier date but did not change the proofmarks to conform to transducer-derived values.

Every time I think it's getting clearer, it gets murkier. If even their transducer system is different than ours, then it would seem that it would not work to convert their bar/kg readings to psi by multiplying x 14.5. Or at least you would not get the same psi reading derived from our transducer testing.

Larry, I went back and re-read Kennett, 1978 on the Belgian proof marks. He mentions the various changes in the proof agreements (Brussels Convention). Reading his various articles, from what I can gather there are 2 levels. The Convention and then minor agreements between Conventions. Belgium adopted the 1924 changes rather quickly while others put it off until 1925.

I am sure since the EU that "fudge factor" has changed. While the English follow CIP, they may not be "ruled" by it since they are not part of the EU in all matters.

Hopefully, some of our European based members will chime in.

Pete

I don't know if it helps, but I noticed this in the book, The Worshipful Company of Gunmakers A History. The UK Proof House self published it in 2008, edited by Stimpson.

"It became clear in 1992 that with many standards of conducting proof being detailed on an international basis it was essential that the Proof House should be modernised and furnished with the latest electronic measuring equipment. By December 1993 the planning stage was complete and, in order that work could continue, a temporary Proof Chamber was erected for use just as had been done, long ago, in the year 1757.

...All work was completed by September [1995]."

I also noticed the following comment about the CIP. "in June 1980 the UK became a Member State. The immediate result was that British proof procedures were required to conform fully to CIP standards and decisions".

Kennett's article on Italian proof runs pretty much along the same lines. Their standard proof of 12,800 psi and the Belgian proof of 12,900 psi are certainly close enough to be considered identical. Likewise the higher proof pressure for smaller gauges.

CIP member countries may have adhered to the same basic standards, even if sometimes they added optional proofs (like the Italian "reinforced proof", which dates from 1962). And continue to use very different proofmarks. The Brits really confused things when they went to the "tons" proofmarks in the 50's.

I'm still wondering whether they all transitioned to transducers at the same time. There are some clues from countries like Spain, which includes the proof pressure as a proofmark. But the ones that don't do that, like Belgium and Italy--or for the ones like England that used crusher values as proofmarks until 2006--leave the situation less than clear.

craigd,

Very useful. Good research!

Larry,

Too bad you can't simply call a proof house and ask questions. Good topic for more research though. Certainly worth an article.

Pete

I noticed both UK Proof Houses have phone and email contacts. The Birmingham museum says most request for information would be free, but if significant research time was involved, they would request a donation. Might help fill in some gaps.

I wonder if the different pressure reading methods were for ammo and powder measuring, and stamped guns didn't actually have pressure read for proof, but survived firing proof cartridges.

--- snip --- and stamped guns didn't actually have pressure read for proof, but survived firing proof cartridges.

Largely correct. Both transducer and crusher methodologies require the test barrel have a hole drilled into the chamber to grant access to obtain the pressure measurement. It's hard to sell a gun with a hole in the chamber :-)

Preliminary or first proof (testing of barrels alone) and final or second proof (testing of the assembled barrels and receiver) is done by firing one or more proof cartridges and examining the barrel/assembled action for unacceptable changes. If no unacceptable changes are found proof has been passed; if unacceptable changes are forum proof has been failed.

The pressure number we find on the barrel flats of a gun identify the pressure standard applied to that barrel/assembled action and do not indicate the pressure actually attained in that gun during proof.

Obviously correct. Proof loads are designed to generate whatever pressure the authority in question (CIP or SAAMI) has determined to be the pressure to which guns passing proof under their standards should be subjected. Those loads are pressure tested in pressure guns. The loads are then fired in the guns subjected to proof testing. If they don't blow up or show any other changes when carefully inspected, they've passed proof.

Similarly, shells for general use are also pressure tested by ammunition manufacturers, and must conform to the service pressure standards (significantly lower than proof pressure standards) established by either SAAMI or CIP for general use.

I have emailed the Birmingham Proofhouse. Awaiting a reply.

Re British proof: Conforming to CIP standards is an issue which does not relate directly to the proofmarks used in CIP countries. For example, although the UK joined the CIP in 1980, they continued to proof their guns at the same level they had been proofing them previously (expressed in "tons"--a language which only the British and Americans speak!) Those proof rules remained in force until 1985. There was a transition period, 85-89, when British guns could be marked either with the old "tons" proofmarks or the new "bars" proofmarks. Those proofmarks (850 bar standard, 1200 bar magnum/superior) were values derived via the old lead crusher measuring system. If, per the quote in a previous post, the "modern electronic equipment" refers to electronic transducers, then that means they switched to transducers in 1992--but continued marking their guns with crusher-derived pressure values until 2006!

Once more I should stress that 1200 bar crusher and 1370 bar transducer are THE SAME PROOF PRESSURE. It's only a question of whether one can multiply a bar (or kg) value times 14.5 to come up with the equivalent psi value. You multiply bars/kgs measured by a lead crusher x 14.5, you get LUP rather than psi. That's the issue in question, rather than an actual change in the proof pressure to which guns were subjected when measured with crushers vs transducers.

I apologize Larry. Though not fact, I was commenting on hints of possible time frames for changing of pressure measuring equipment, not conversion formulas.

I made the CIP comment because apparently the confusing and differing marking choices are in full compliance. In the same book, I noticed that a 'Working Group' of the CIP 'Technical Committee' had 'Calibration of Piezo Electric Transducers' as a task to work on in 2008. It explains that if a standard could be determined, it would not be up for vote by Member States till the next meeting, two years later.

It seems to point out that CIP compliance allows/ed variation in methodology not just marking, significantly later historically than the likely introduction of the electronic transducer. Best of luck with the folks in Birmingham. The '92 to '95 modernization comment I quoted was for the London Proof House.